Method for extracting alpha-glucosidase restraining agent effective ingredient from plants

A technology of glucosidase and active ingredients, which is applied in the preparation of Chinese herbal medicines and the fields of chemical and chemical engineering, can solve the problems of no α-glucosidase inhibitors, and achieve the effects of no pollution to the environment, simple process and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

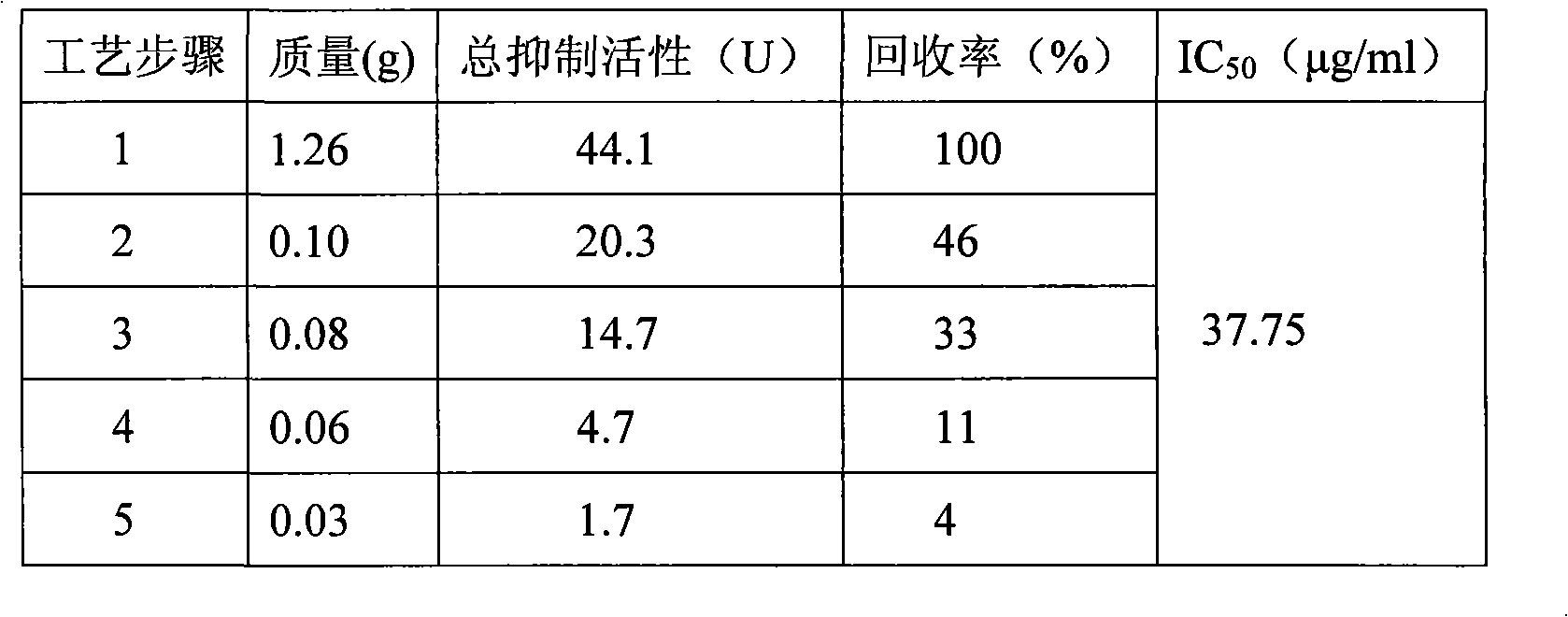

Examples

Embodiment 1

[0014] In the present embodiment, the extraction process and steps of α-glucosidase inhibitor are as follows:

[0015] (1) First, crush 2g of plant leaves; put a 250ml beaker and add 50% ethanol solution at a ratio of 1:40 (g / ml), shake at room temperature for 3h; centrifuge at 8000rpm / min for 20min at room temperature, and harvest the supernatant; plant residues are added 50% ethanol solution, repeat the extraction 3 times; combine the 3 extractions;

[0016] (2) Recover the ethanol solution with a rotary evaporator to obtain 0.72g of solid, add 100ml of hot water for redissolving; add ethyl acetate solution for extraction at a ratio of 1:1, collect 85ml of the aqueous phase; in the harvest solution at a ratio of 1:1 Add n-butanol solution for extraction, collect the water phase part, spin dry to obtain 0.48g solid, 5ml hot water redissolving for use;

[0017] (3) MARC (macroporous adsorption resin) chromatography on the above sample (filler height 35cm, column diameter 2.6c...

Embodiment 2

[0020] The process of the present embodiment 2 is exactly the same as that of the embodiment 1, and its steps are as follows:

[0021] (1) First, crush 2g of plant leaves; put a 250ml beaker and add 50% ethanol solution at a ratio of 1:40 (g / ml), shake at room temperature for 3h; centrifuge at 8000rpm / min for 20min at room temperature, and harvest the supernatant; plant residues are added 50% ethanol solution, repeat the extraction 3 times; combine the 3 extractions;

[0022] (2) Recover the ethanol solution with a rotary evaporator to obtain 0.81g of solid, add 100ml of hot water for redissolving; add ethyl acetate solution for extraction at a ratio of 1:1, collect 89ml of the aqueous phase; in the harvest solution at a ratio of 1:1 Add n-butanol solution for extraction, collect the water phase part, spin dry to obtain 0.52g solid, redissolve in 5ml hot water for use;

[0023] (3) MARC (macroporous adsorption resin) chromatography on the above sample (filler height 35cm, col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com