Preparation of surface crosslinked antimicrobial compound film

A composite membrane and cross-linking agent technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of antibacterial substance loss, membrane antibacterial performance decline, loss, etc., to achieve stable antibacterial composite layer, antibacterial Long-lasting effect and strong antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

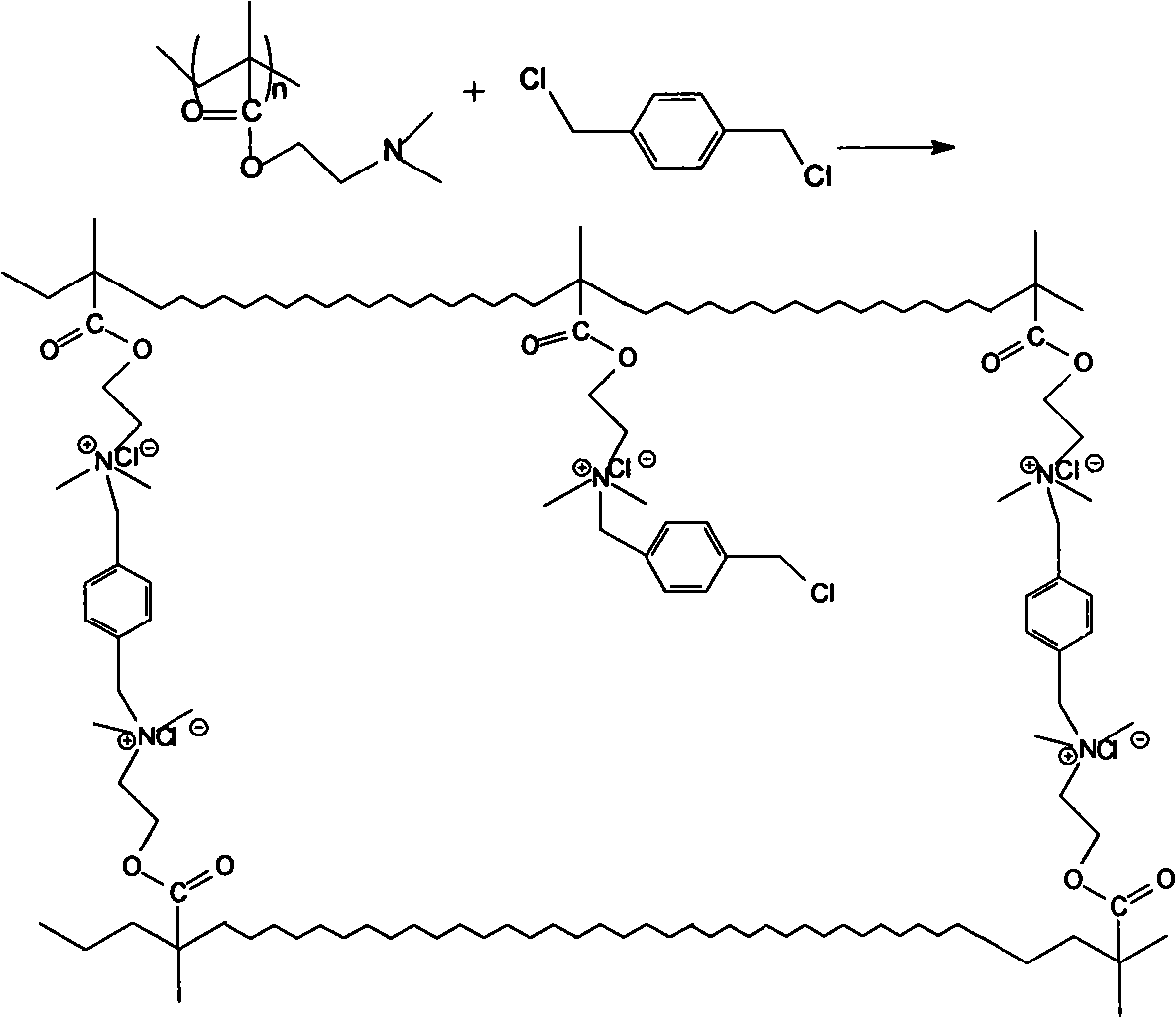

Method used

Image

Examples

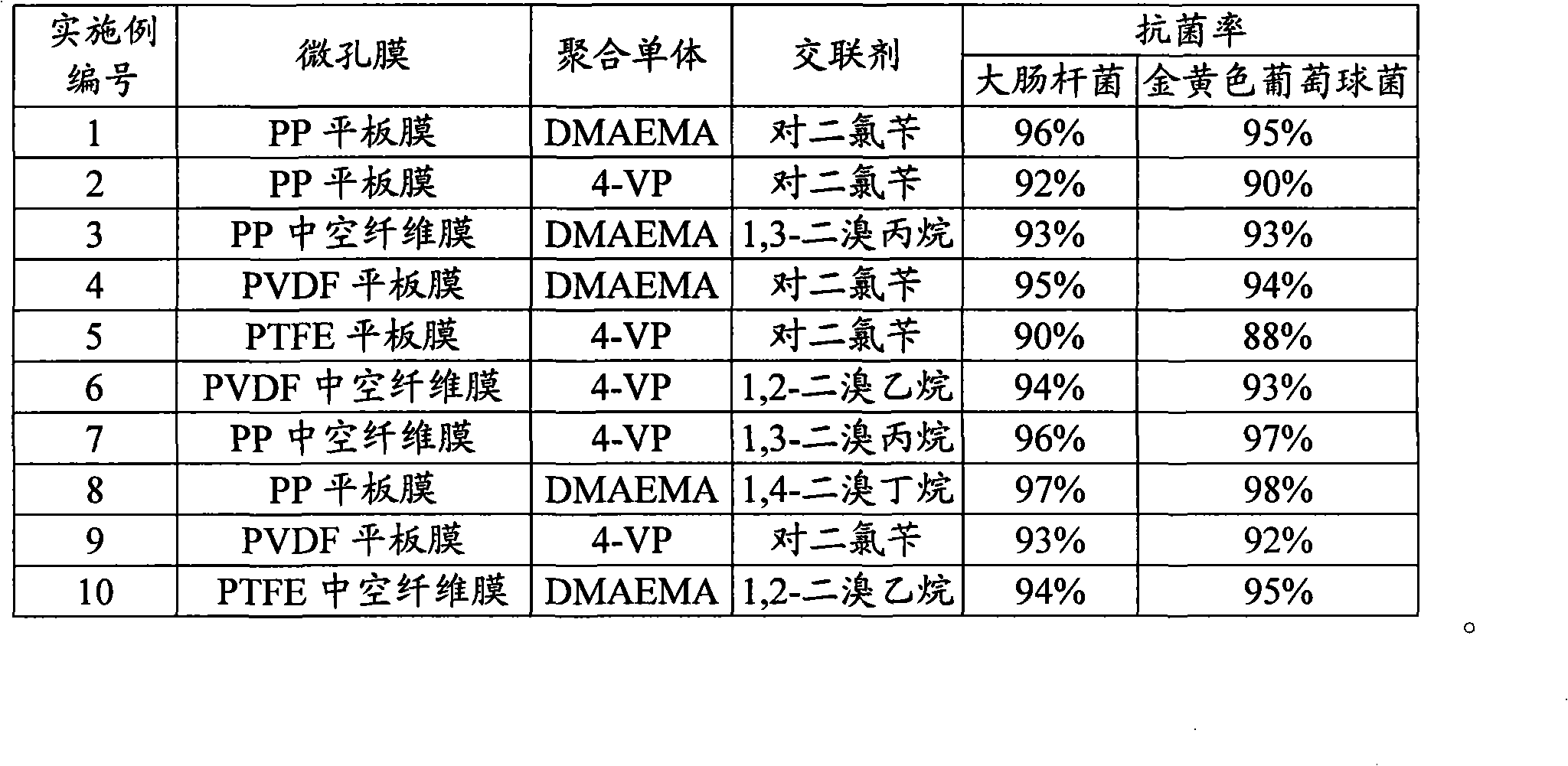

Embodiment 1

[0021] Inject 2 ml of dimethylaminoethyl methacrylate (DMAEMA) and 0.002 g of azobisisobutyronitrile (AIBN) into the ampoule and mix evenly. Bubble nitrogen for 10 minutes to drive away oxygen, then seal and place at 45°C The polymerization reaction was carried out in a constant temperature shaking water bath for 48 hours. Dissolve the reaction product with ethanol, precipitate with petroleum ether to remove unreacted monomer, and dry to obtain the polymer. The flat polypropylene microporous membrane was immersed in a 10 g / L ethanol solution of polydimethylaminoethyl methacrylate obtained above, shaken at 30° C. for 6 hours, and then taken out to dry. Then the dried film was placed in a 10 g / L ethanol solution of p-dichlorobenzyl, and in-situ cross-linking and quaternization were carried out at 30° C. for 12 hours. Finally, ethanol and deionized water were used to wash off the unreacted p-dichlorobenzyl and uncrosslinked polymers on the surface of the membrane in sequence, an...

Embodiment 2

[0023] Inject 2 ml of 4-vinylpyridine (4-VP) and 0.001 g of azobisisobutyronitrile (AIBN) into the ampoule and mix evenly. Bubble nitrogen for 10 minutes to drive away oxygen, then seal and place at a constant temperature of 60°C Polymerization was carried out in a shaking water bath for 24 hours. Dissolve the reaction product with ethanol, precipitate with petroleum ether to remove unreacted monomer, and dry to obtain the polymer. The flat polypropylene microporous membrane was immersed in a 2 g / L ethanol solution of polydimethylaminoethyl methacrylate obtained above, shaken at 40° C. for 2 hours, and then taken out to dry. Then the dried film was placed in 2 g / L ethanol solution of p-dichlorobenzyl, and in-situ cross-linking and quaternization were carried out at 50°C for 24 hours. Finally, ethanol and deionized water were used to wash off the unreacted p-dichlorobenzyl and uncrosslinked polymers on the surface of the membrane in sequence, and the antibacterial composite me...

Embodiment 3

[0025] Inject 2 ml of dimethylaminoethyl methacrylate (DMAEMA) and 0.001 g of dibenzoyl peroxide (BPO) into the ampoule and mix well. Bubble nitrogen for 10 minutes to drive away oxygen, then seal and place at 75°C The polymerization reaction was carried out in a constant temperature shaking water bath for 24 hours. Dissolve the reaction product with ethanol, precipitate with petroleum ether to remove unreacted monomer, and dry to obtain the polymer. The polypropylene hollow fiber microporous membrane was immersed in a 5 g / L acetone solution of polydimethylaminoethyl methacrylate obtained above, shaken at 20° C. for 3 hours, and then taken out to dry. Then the dried film was placed in 20 g / L 1,3-dibromopropane ethanol solution, and in-situ cross-linking and quaternization were carried out at 30° C. for 6 hours. Finally, ethanol and deionized water were used to wash off the unreacted 1,3-dibromopropane and uncrosslinked polymer on the surface of the membrane in sequence, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com