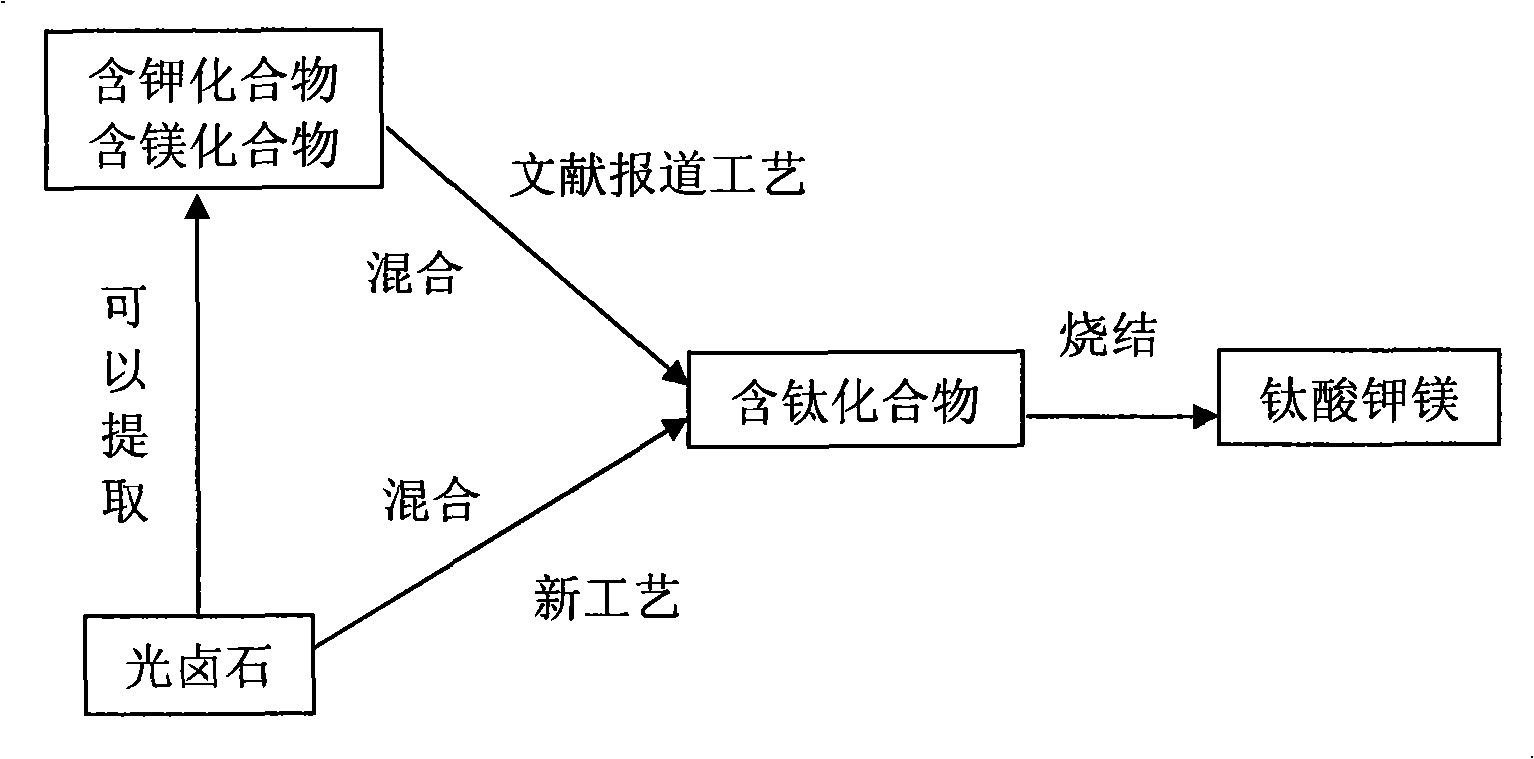

Method for preparing kalium-magnesium titanate by carnallite

A technology of potassium magnesium titanate and carnallite, applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., to achieve the effects of reducing raw material costs, improving production efficiency, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

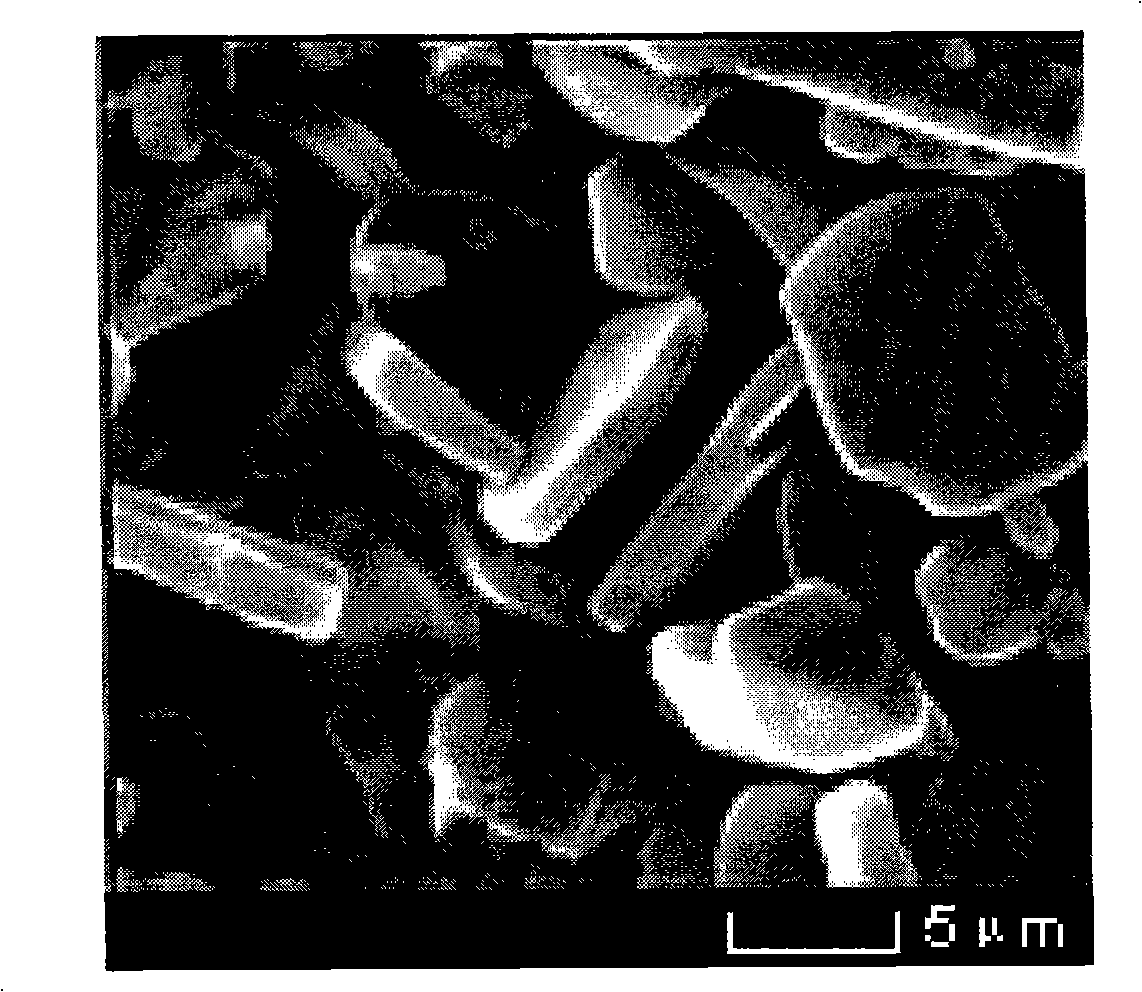

[0025] Carnallite, TiO 2 (Anatase), KOH and KNO 3 by KMgCl 3 :TiO 2 : K 2 The ratio of O=1:4.5:1.5 is uniformly mixed, the mixture is sintered in a high-temperature furnace to 1000°C, kept for 1 hour, and then cooled with the furnace; the sintered product is pulverized, washed with water, filtered, dried, and then heated at 700°C Under heat treatment. The obtained product is potassium magnesium titanate lamellae whose arithmetic mean value of equivalent length and equivalent width is 1-5 μm, the ratio of equivalent length and equivalent width is 1-3, and the average thickness is 0.05-1 μm; Fluorescence X-ray diffraction analysis, its chemical formula is K 0.8 Mg 0.4 Ti 1.6 o 4 (Such as figure 2 shown). Figure 4 K before and after heat treatment 0.8 Mg 0.4 Ti 1.6 o 4 The comparison of the X-ray peak intensities of the lamellar crystals shows that the crystallinity of the product without heat treatment is relatively poor.

Embodiment 2

[0027] Carnallite, TiO 2 (rutile type) and K 2 CO 3 by KMgCl 3 :TiO 2 : K 2 The ratio of O=1:4.5:2.5 is uniformly mixed, and the mixture is sintered in a high-temperature furnace to 1100°C, kept for 30 minutes, and then cooled with the furnace; the sintered product is crushed, washed with water, and filtered; then heat-treated at 300°C. The obtained product is potassium magnesium titanate lamellar crystals whose arithmetic average of equivalent length and equivalent width is 50 μm, ratio of equivalent length and equivalent width is 1.5, and average thickness is 2-5 μm; Diffraction analysis, its chemical formula is K 0.6 Mg 0.4 Ti 1.6 o 4 .

Embodiment 3

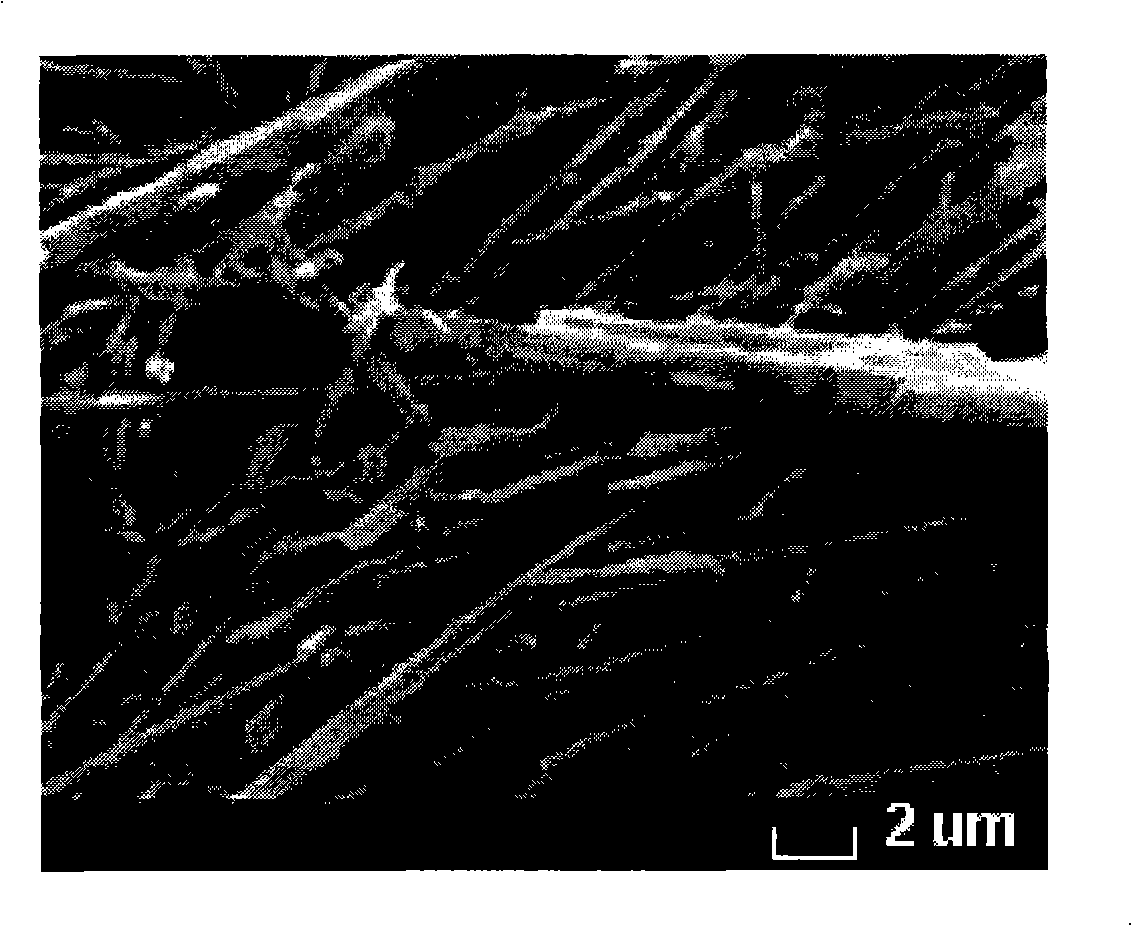

[0029] Carnallite, hydrated titanium oxide and KNO 3 by KMgCl 3 :TiO 2 : K 2 The ratio of O=1:3.5:1 was uniformly mixed, the mixture was sintered in a high-temperature furnace to 800° C., kept for 6 hours, and then cooled with the furnace; the rest of the operations were the same as in Example 1. The resulting product is a potassium magnesium titanate whisker with a length of 10-20 μm and a diameter of 0.5 μm; analyzed by X-ray diffraction, its chemical formula is K 2 MgTi 7 o 16 (Such as image 3 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com