System and method for innocent treatment of garbage flying ash

A technology of harmless treatment and garbage fly ash, which is applied in the field of hazardous waste treatment and disposal, can solve the problems that the diffusion of dioxin cannot be avoided, and the leaching of heavy metals cannot be guaranteed to meet the standards, so as to improve the quality of fly ash, avoid release, and improve the quality of materials. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

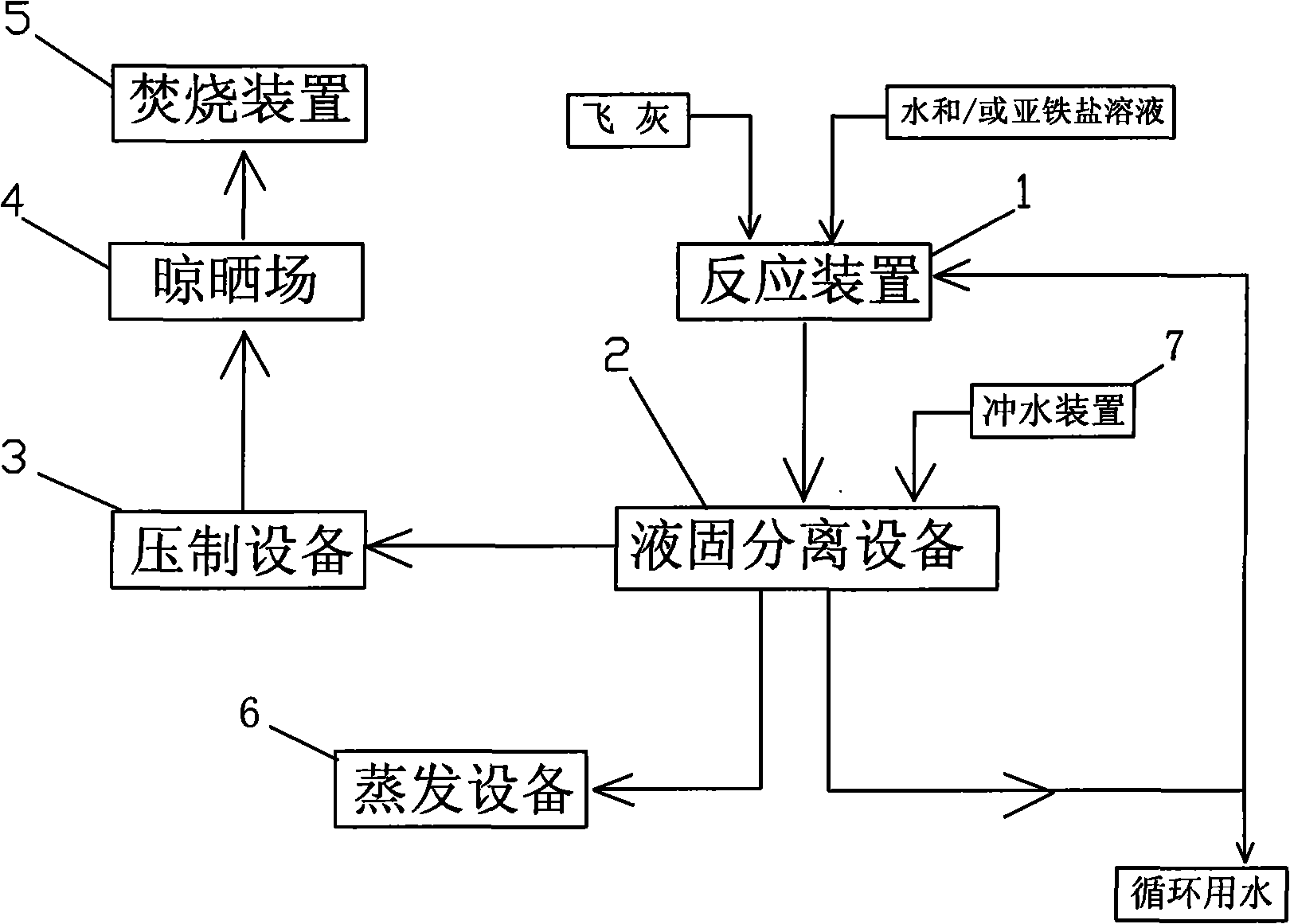

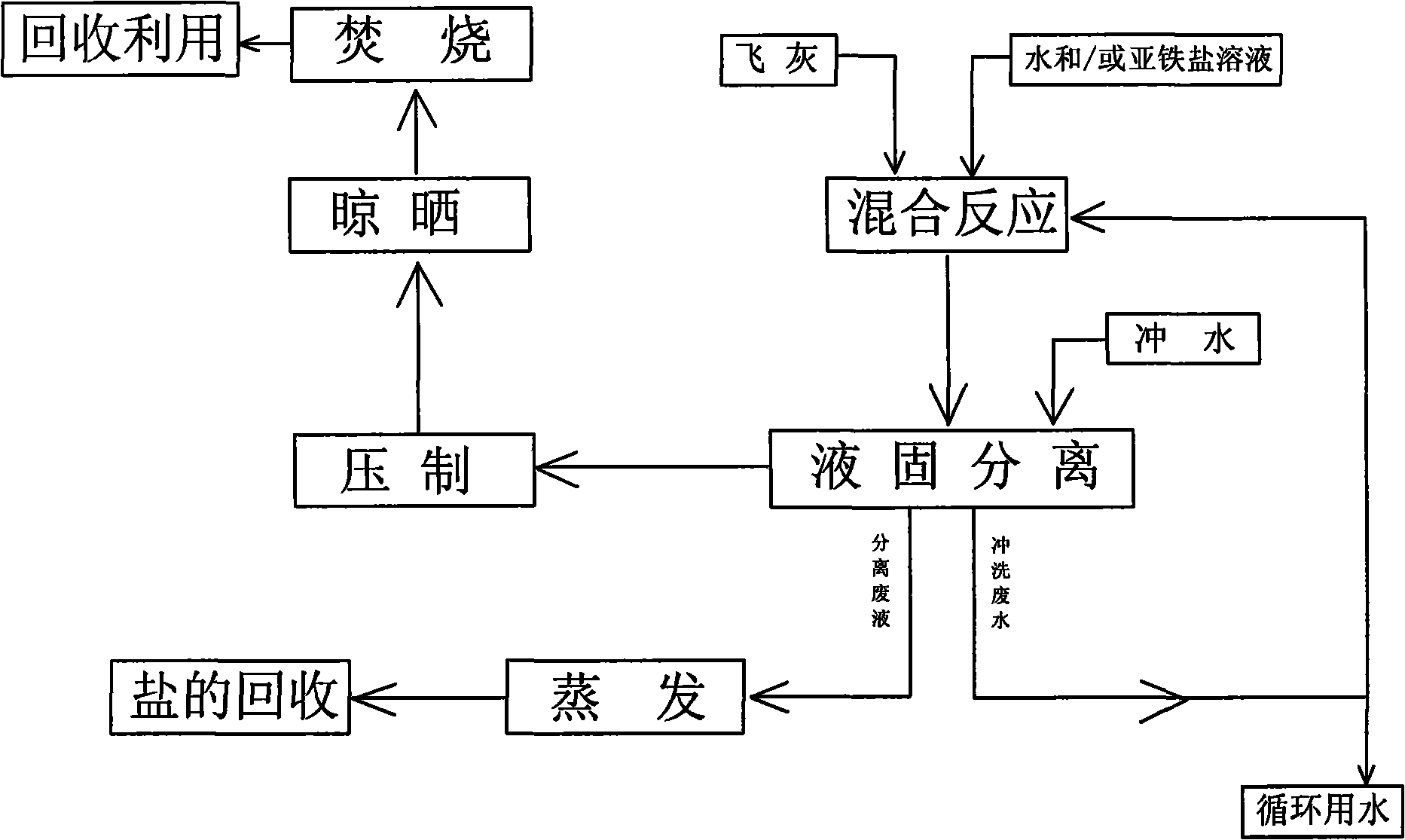

Image

Examples

example 1

[0034] The fly ash collected by a grate type garbage incinerator filter bag dust collector, the content of some heavy metals, chlorine and alkali metals are shown in Table 1:

[0035] Table 1 Contents of some heavy metals, chlorine and alkali metals in the fly ash of an incinerator

[0036] Element type

[0037] The fly ash shown in Table 1, with 4.5% FeSO 4The solution is fully mixed with the fly ash in the reaction device 1 according to the liquid-solid ratio = 1.5: 1, and after being stirred evenly (the corresponding iron / ash mass ratio is 1: 40), a mixture in a liquid-solid state is formed, and then sulfuric acid or titanium dioxide waste is used to The acid adjusts the pH value of the system to 11 ± 0.15; the above-mentioned mixture is sent to the vacuum filtration equipment 2 for liquid-solid separation; the waste liquid after the suction filtration is pumped into the spray hot air drying tower 6 for spray evaporation ( Close the pipeline that vacuum filtratio...

example 2

[0039] For the fly ash shown in Table 1, the middle water is fully mixed with the fly ash in the reaction device 1 according to the liquid-solid ratio=3.5: 1, and 300kg of ferrous sulfate heptahydrate is added to each ton of fly ash simultaneously (the corresponding iron / ash mass ratio is 1:16.7), and then stirred until the pH value of the system naturally rose to 10, the ash-water mixture was sent to the filter press 2 for liquid-solid separation, and the separated waste liquid was sent to the multi-effect evaporator 6 for evaporation and recovery of salt (this Close the pipeline that filter press equipment 2 is connected with reaction device 1 when closing). After the press filtration is basically completed, reclaimed water 1.5 times the mass of the original fly ash is sent through the flushing device 7, and the ash cake is washed in the filter press equipment 2, and the separated waste water is sent to the front-end reaction device 1 for use with the fly ash. Ash mixed trea...

example 3

[0041] The content of some heavy metals, chlorine and alkali metals in the fly ash collected by a grate type garbage incinerator filter bag filter is shown in Table 2:

[0042] Table 2 Contents of some heavy metals, chlorine and alkali metals in the fly ash of an incinerator

[0043] Element type

Pb

mg / kg

Cr

Mg / kg

Cd

mg / kg

Zn

mg / kg

Cl

g / kg

CaO

g / kg

Na 2 o

g / kg

K 2 o

g / kg

content

1395

134.9

91

3175

129

221

34.3

38.7

[0044] The unpurified ferrous nitrate solution is mixed and stirred with the fly ash in the reaction device 1 according to the mass ratio of iron / fly ash=1:90, and the liquid-solid ratio is 1.8:1; The pH value of the fly ash is adjusted to 10.5 ± 0.15, and then the fly ash-water solution is sent to the vacuum filtration equipment 2 for liquid and solid separation, and the separated liquid is sent to the spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com