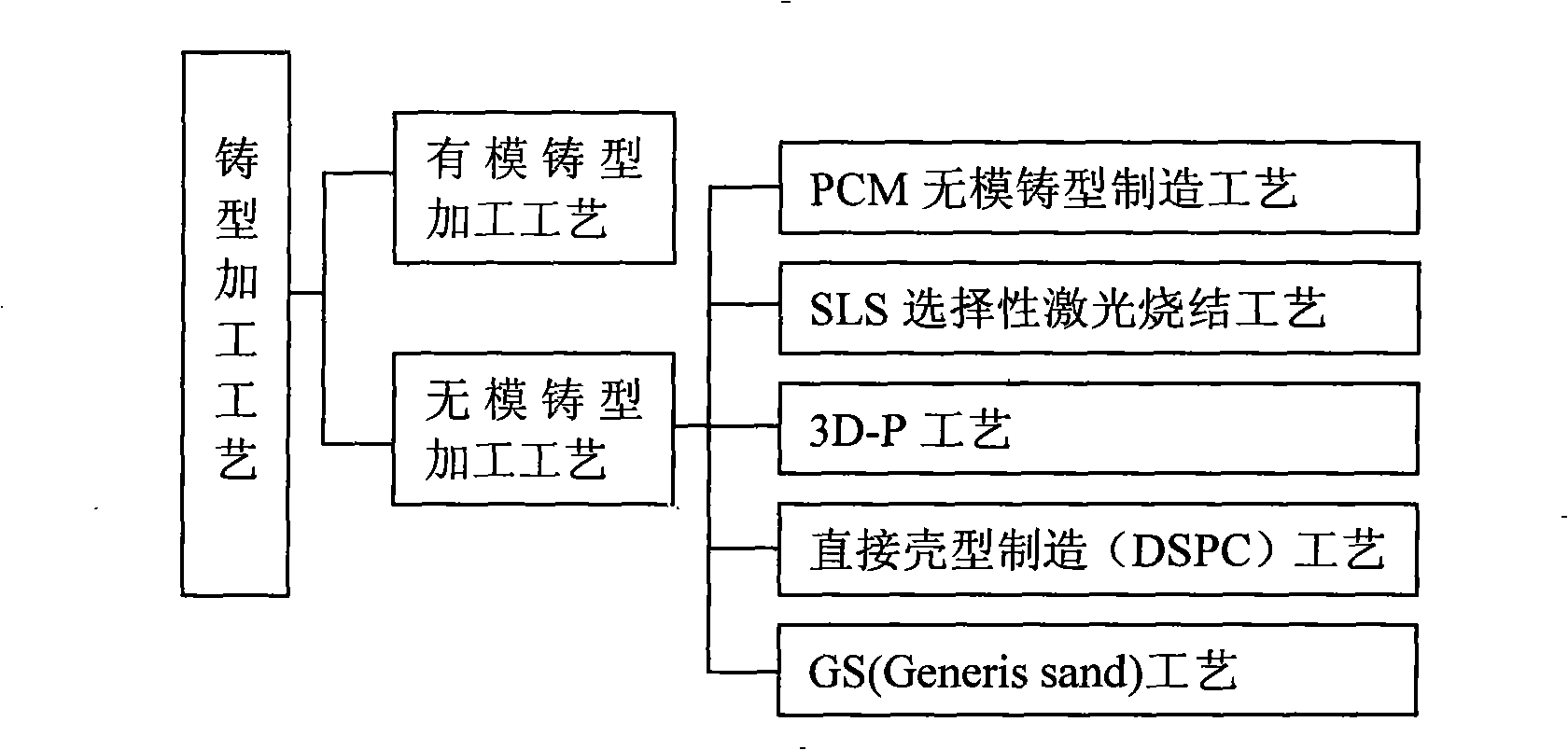

Non die-casting type digitalization fast manufacturing method

A manufacturing method and rapid technology, applied in the directions of casting molds, casting mold components, manufacturing tools, etc., can solve the problems of high product development cost, difficulty in cleaning sand, and high equipment cost, shortening the processing cycle, shortening the processing time, and saving raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

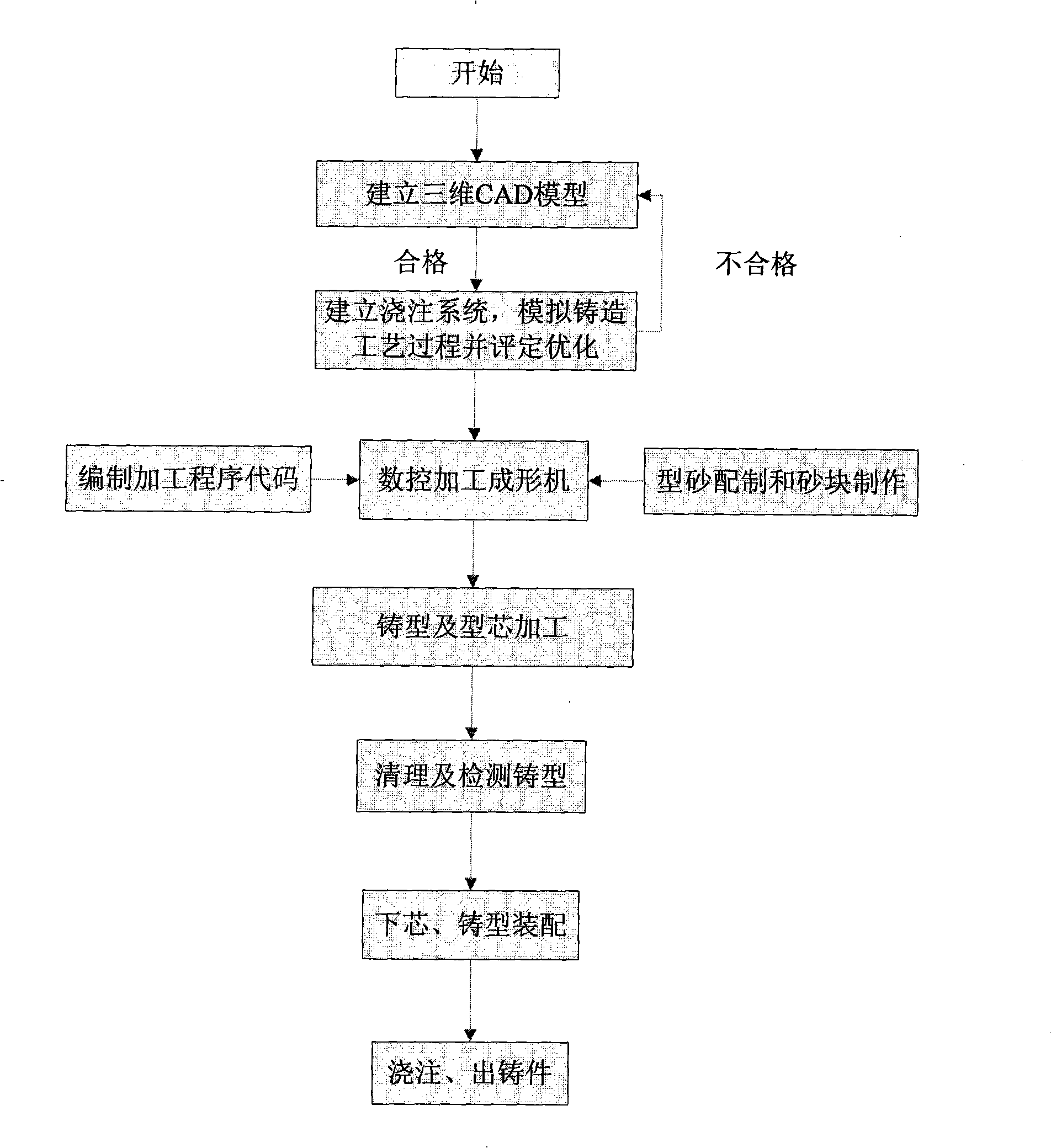

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: A 20×20×30 mm cubic mold cavity is manufactured by using the present invention.

[0033] (1) Utilize computer to establish a cube of 20×20×30mm;

[0034] (2) Determine the size of the sand blank according to the size of the part, and use the casting simulation software to establish the casting system plan, and determine that it is divided into upper and lower sand blanks without sand cores;

[0035] (3) The washed sand with the particle size of the original sand is 50 / 80 and 100 / 200 is mixed according to the ratio of 1:2, the amount of curing agent accounts for 50% of the resin, and the amount of resin added accounts for 1.5% of the washed sand. The mixed molding sand should be First add curing agent;

[0036] (4) According to the outline to be processed, the numerical control program is compiled, and the depth of the mold cut out is 15mm. The processing parameters are: the feed rate F is 100mm / min, and the rotating speed of the milling cutter is 640r / min...

Embodiment 2

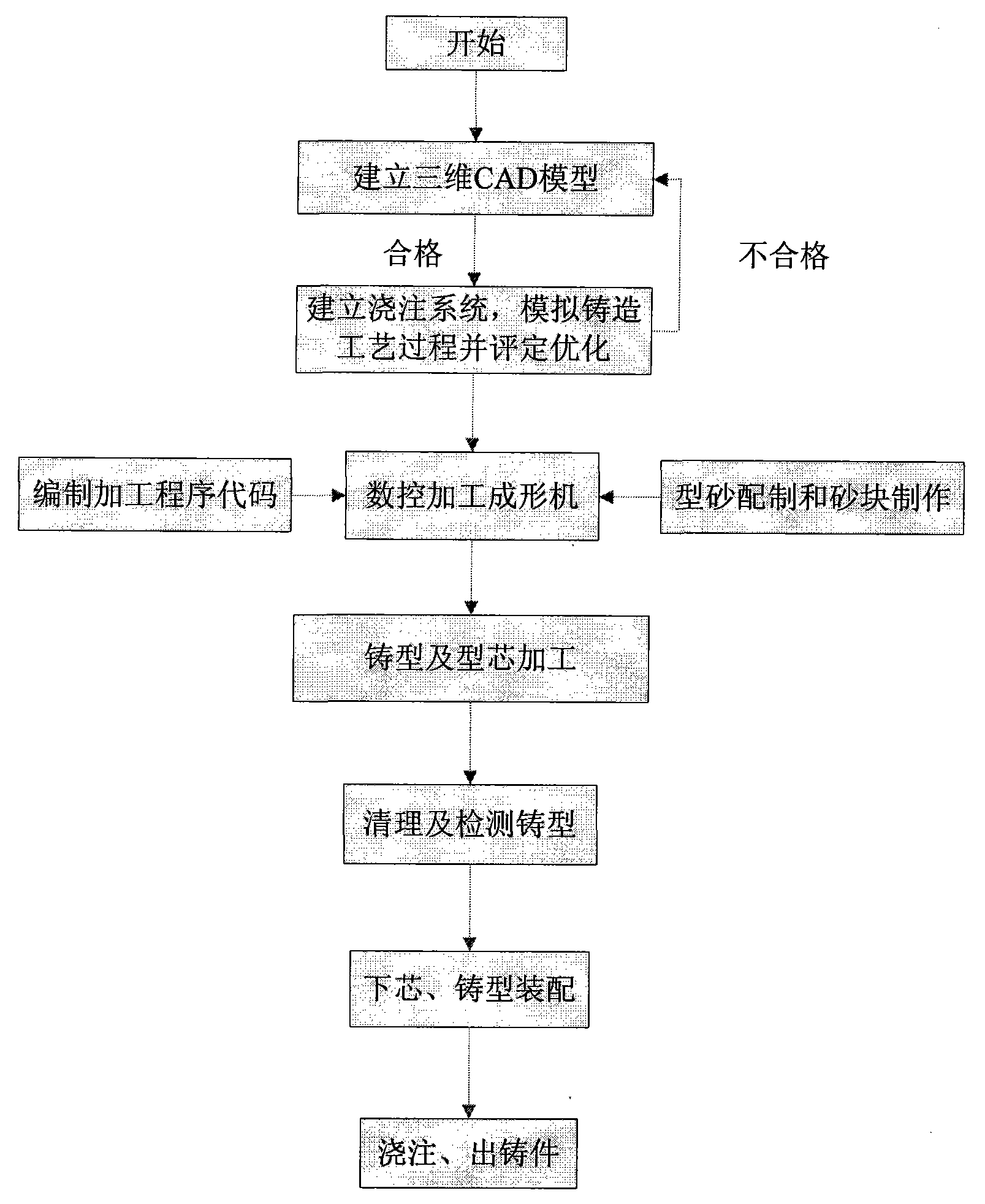

[0041] Embodiment 2: A 60×60×40mm cuboid is manufactured by using the present invention, and a through hole with a diameter of 30mm is formed on the 60×60mm surface.

[0042] (1) Use 3D modeling software to build a cube of 60×60×40mm, and drill a through hole with a diameter of 30mm;

[0043] (2) Determine the size of the sand blank according to the size of the part, and establish the casting system plan in the casting simulation software, and determine that it is divided into upper and lower sand blanks, without sand cores;

[0044] (3) The ceramic powder with the particle size of the original sand is 30 / 50 and the washed sand of 50 / 80 are mixed according to the ratio of 3:1, the amount of curing agent accounts for 50% of the resin, and the amount of resin added accounts for 3% of the washed sand;

[0045] (4) According to the outline to be processed, the numerical control program is compiled. The processing parameters are that the feed rate F is 80mm / min, and the rotating spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com