Technique for preparing alpha-semi-hydrated gypsum from chemical gypsum

A technology for chemical gypsum and hemihydrate gypsum is applied in the field of chemical gypsum to prepare α-hemihydrate gypsum, which can solve problems such as product performance decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

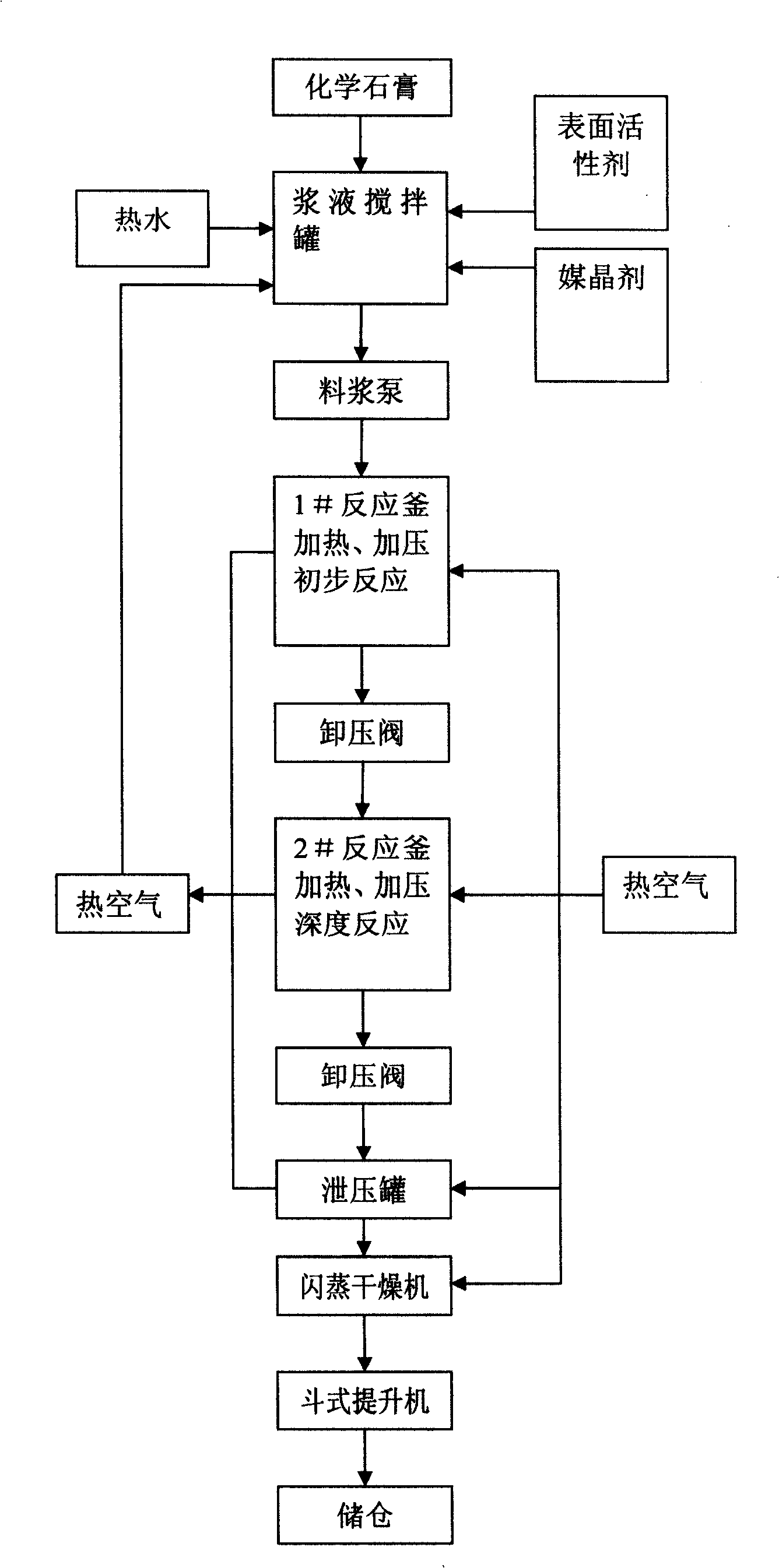

Image

Examples

example 1

[0019] Transport the chemical gypsum powder to the slurry mixing tank to prepare gypsum slurry with a slurry concentration of 50wt%, and at the same time inject a crystallization agent into the mixing tank, the total concentration of the crystallization agent is 4wt% of the total concentration of the slurry, and the composition is: Al 2 (SO 4 ) 3 1wt%, CaCl 2 1wt%, KCl 1wt%, MgCl 2 1wt%, and at the same time add soapy water with a concentration of 0.1wt% of the total concentration of the slurry, and at the same time feed hot water for stirring, so that the crystallization agent and surfactant are fully contacted with the material. The stirred slurry is transported to the 1# preliminary reaction kettle through the slurry pump, the pressure is 1.3MPa, the reaction temperature is 220°C, the stirring speed is 100 rpm, the dynamic residence time of the material is 5 minutes, and hot air is introduced at the same time Heating and heat preservation are carried out to make the d...

example 2

[0021] Transport the chemical gypsum to the slurry mixing tank to prepare gypsum slurry with a slurry concentration of 50wt%, and at the same time inject a crystallization agent into the mixing tank, the concentration of the crystallization agent is 0.1wt% of the total concentration of the slurry, and the composition is Al 2 (SO 4 ) 3, and at the same time add industrial pulp waste liquid, the concentration is 3wt% of the total concentration of the slurry, while feeding hot water for continuous stirring, so that the crystallization agent and surfactant are fully contacted with the material. The stirred slurry is input into 1# preliminary reactor, the pressure is 0.6MPa, the reaction temperature is 150°C, the stirring speed is 60 rpm, the dynamic residence time of the material is 25 minutes, and hot air is introduced at the same time for heating and heat preservation. The slurry is transported to the 2# deep reaction kettle through the pressure relief valve using the combined ...

example 3

[0023] Transport the chemical gypsum to the slurry mixing tank to prepare gypsum slurry with a slurry concentration of 75wt%, and inject a crystallization agent into the stirring tank at the same time, the concentration of the crystallization agent is 3wt% of the total concentration of the slurry, and the composition is: CaCl 2 , and add surfactant simultaneously to be 10wt% of the total concentration of slurry: 5wt% of soapy water, 5wt% of industrial paper pulp waste liquid, pass into hot water and stir continuously simultaneously, make crystallization agent and surfactant fully contact with material. Transfer the stirred slurry to 1# preliminary reaction kettle, the pressure is 0.4MPa, the reaction temperature is 100°C, the stirring speed is 40 rpm, the dynamic residence time of the material is 45 minutes, and hot air is introduced at the same time for heating and heat preservation . Through the pressure relief valve, the slurry is transported to the 2# deep reaction kettle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com