Metal semiconductor composite ultra-distinguish film and preparation method thereof

A metal-semiconductor, super-resolution technology, applied in the field of optical storage, can solve the problems of focusing spot energy attenuation, damage to the film and substrate, shortening the life of the disc, etc., to achieve high light energy utilization, simple preparation method, fast signal response Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

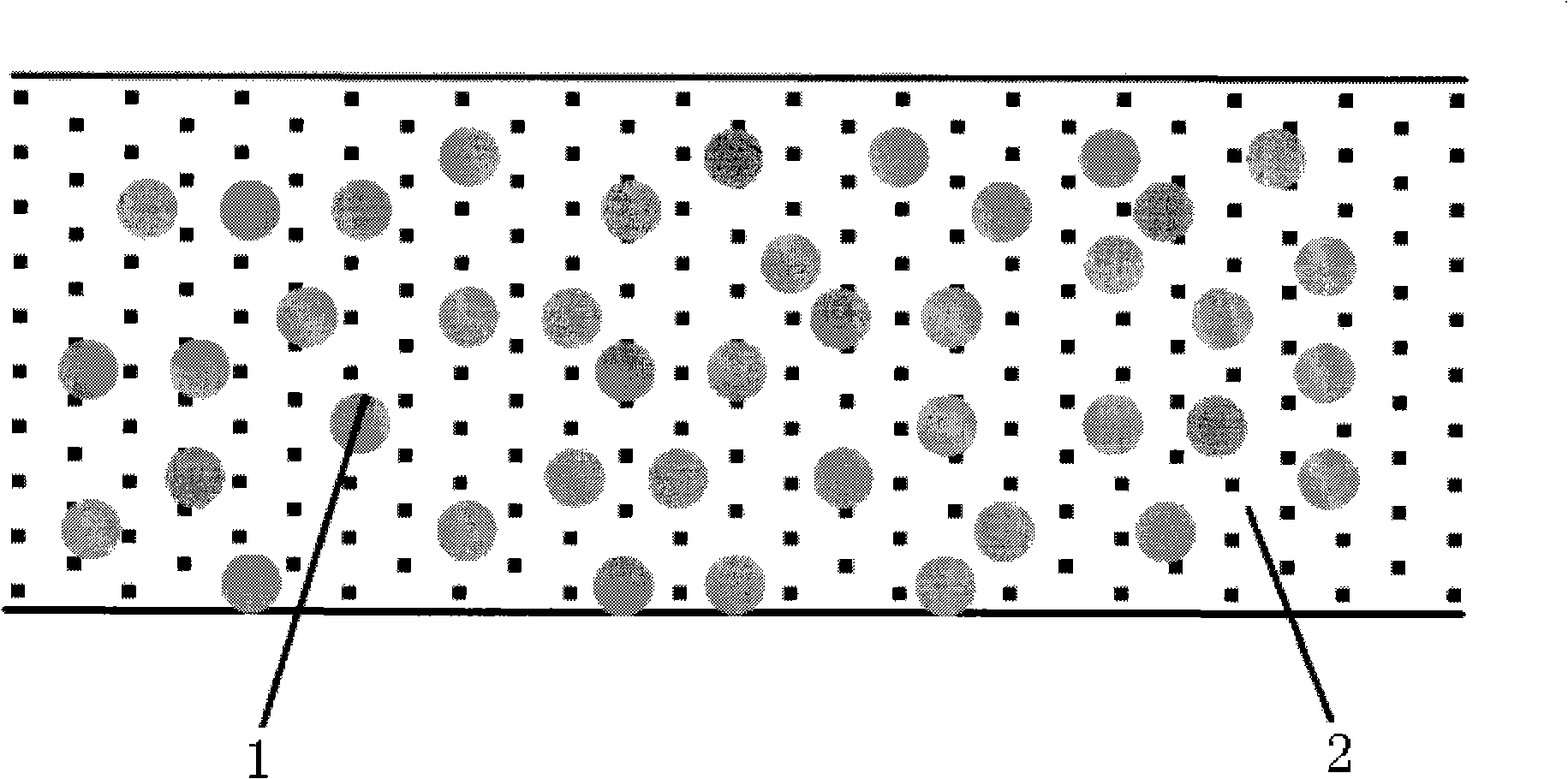

[0021] Taking the Ag-Si composite film as an example, a mixed target with a molar ratio of Ag and Si of 1:9 is used as the sputtering target. The substrate is a polycarbonate disc with a thickness of 1.2 mm. The engraved pit points are used as information points. Pump the background vacuum of the sputtering chamber to 6.0×10 -4 After Pa, argon gas is introduced, the flow rate of argon gas is 70 sccm, the sputtering pressure is adjusted to 0.6Pa, the sputtering power is 250W, and the composite target is pre-sputtered for 5 minutes to remove the pollution on the surface of the composite target, and then sputtered for 10 minutes , to obtain the desired Ag-Si composite film. figure 1 It is a structural schematic diagram of the metal-semiconductor composite thin film of this embodiment, and the thin film is composed of a semiconductor matrix 2 and nanometer metal (Ag or Au or Pt or Pd) particles 1 buried in it or located on its surface. In order to test its super-resolution effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com