Solar energy battery copper-indium-gallium-selenium film key target material and preparation method thereof

A technology of solar cells and copper indium gallium selenide, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve problems such as complex sputtering process and film quality problems, and achieve good product stability and low cost. Low, increased controllability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

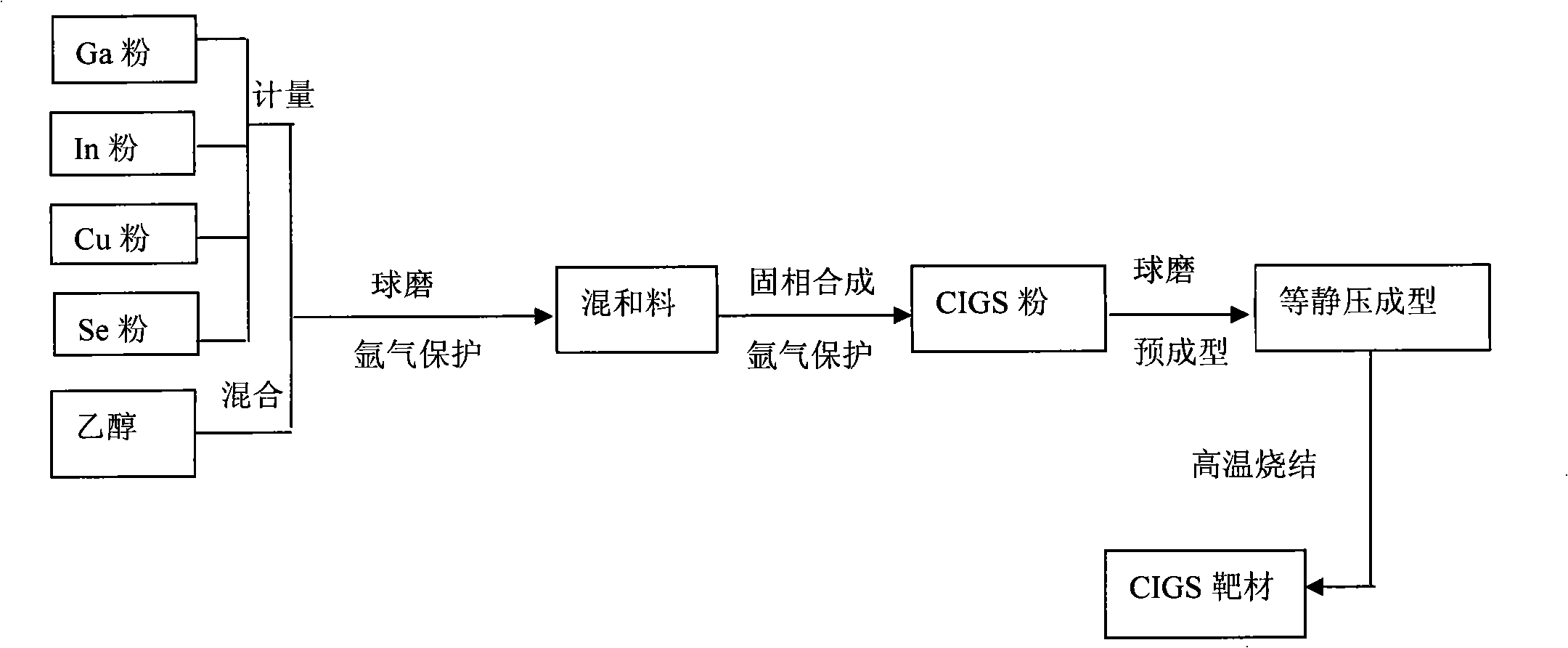

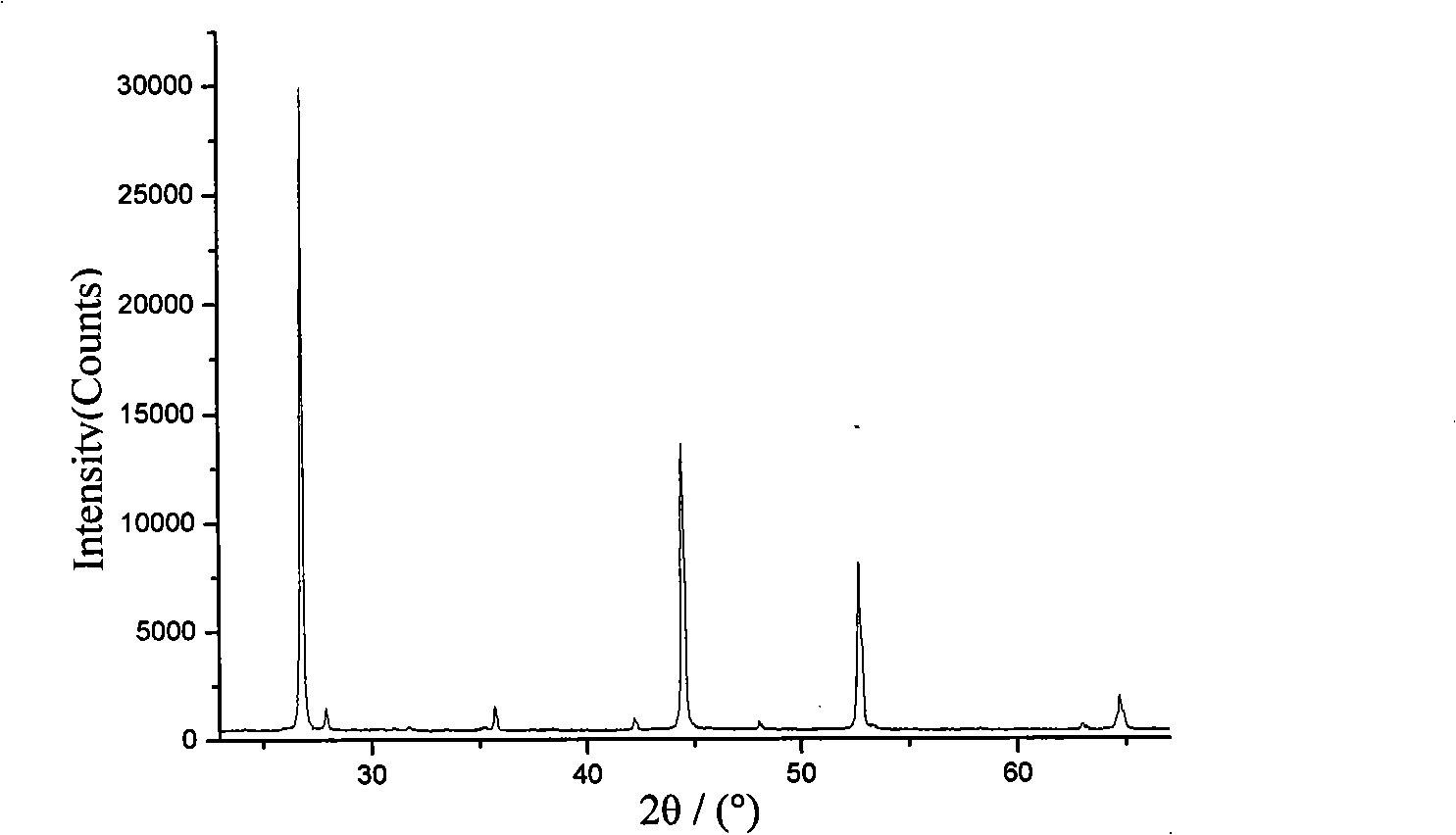

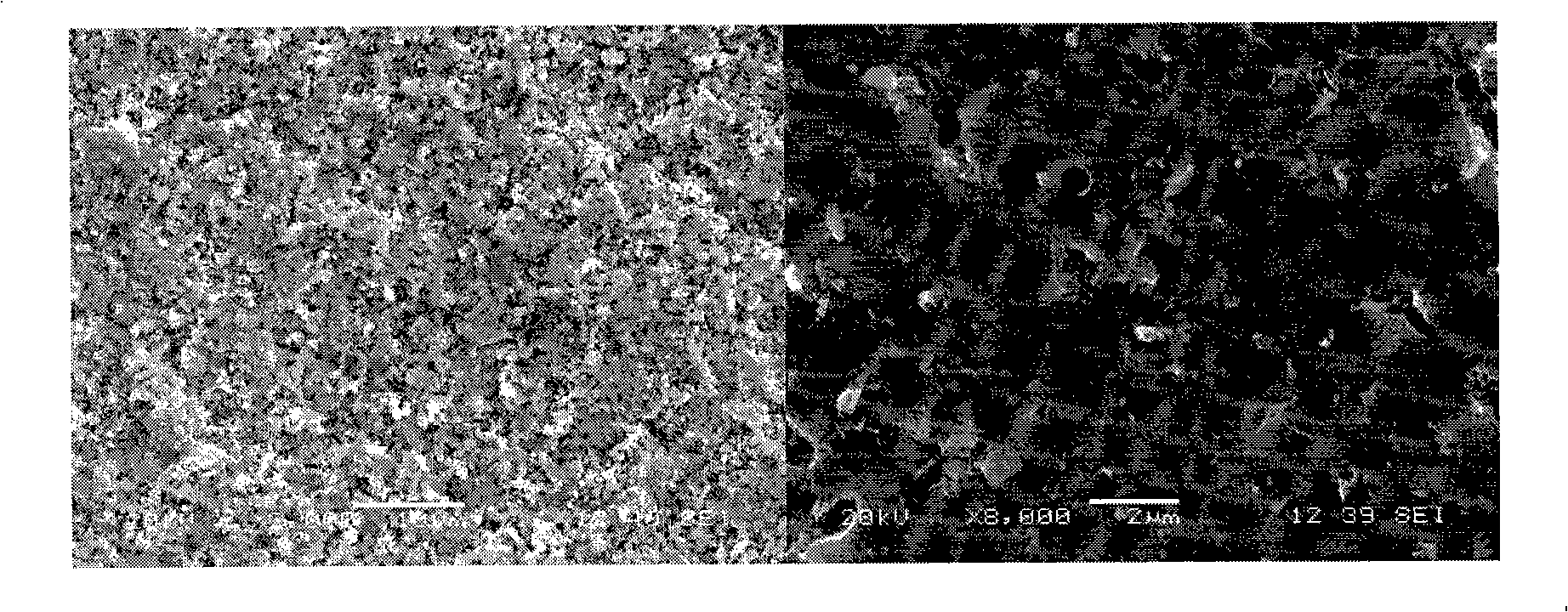

[0022] Using Cu powder, In powder, Ga powder, and Se powder as raw materials, according to the molar ratio Cu:In:Ga:Se=1:0.6:0.2:1.8, weigh 994.5g Cu powder, 1075.5gIn powder, 216.0gGa powder, 2214.0gSe powder powder, add 3500ml of absolute ethanol as a medium, pour it into a ball mill jar filled with argon, and ball mill the mixture at a speed of 100r / min for 24 hours. After mixing, put it into a corundum crucible, dry it in vacuum, put it into an argon-protected high-temperature furnace, raise the temperature to 550°C, keep it warm for 1 hour, and cool to room temperature. The argon gas was cut off, and the reaction product was ball milled for 3 hours to obtain CIGS powder for future use. Take 4000g of the above CIGS powder and add it into an axially pressurized mold, and preform it under a molding pressure of 5MPa. The preformed CIGS test block is tightly wrapped and molded under isostatic pressure of 200MPa. The formed test block was placed in a high-temperature furnace ...

Embodiment 2

[0024] Using Cu powder, In powder, Ga powder, and Se powder as raw materials, according to the molar ratio Cu:In:Ga:Se=1:0.7:0.3:2, weigh 980.1g Cu powder, 1232.6g In powder, 321.7g Ga powder, 2415.6g Se powder powder, add 4000ml of absolute ethanol as a medium, pour it into a ball mill jar filled with argon, and ball mill the mixture at a speed of 130r / min for 24 hours. After mixing, put it into a corundum crucible, dry it in vacuum, put it into an argon-protected high-temperature furnace, raise the temperature to 350°C, keep it warm for 1.5 hours, and cool to room temperature. The argon gas was cut off, and the reaction product was ball milled for 3 hours to obtain CIGS powder for future use. Take 4000g of the above CIGS powder and add it into an axially pressurized mold, and preform it under a molding pressure of 5MPa. The preformed CIGS test block is tightly wrapped and molded under isostatic pressure of 200MPa. The formed test block was placed in a high-temperature furn...

Embodiment 3

[0026] Using Cu powder, In powder, Ga powder, and Se powder as raw materials, according to the molar ratio Cu:In:Ga:Se=1:0.9:0.5:2.2, weigh 901.0g Cu powder, 1457.5gIn powder, 492.9gGa powder, 2448.6gSe powder, add 4306ml of ethanol as medium, pour it into a ball mill jar filled with argon, and ball mill the mixture at a speed of 160r / min for 12 hours. After mixing, put it into a corundum crucible, dry it in vacuum, put it into an argon-protected high-temperature furnace, raise the temperature to 400°C, keep it warm for 2 hours, and cool to room temperature. The argon gas was cut off, and the reaction product was ball milled for 4 hours to obtain CIGS powder for future use. Take 5000g of the above CIGS powder and add it into an axially pressurized mold and preform it under a molding pressure of 10MPa. The preformed CIGS test block is tightly wrapped and molded under 300MPa isostatic pressure. Put the formed test block into a high-temperature furnace protected by argon and he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com