Self-supporting transmission metal grating based on nanometer stamping technology and its preparation method

A technology of metal grating and nanoimprinting, which is applied in nanoscale structure devices and micro-nano processing technology to make nanoscale structure devices, space detection, and nuclear fusion detection. Simple, low cost, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

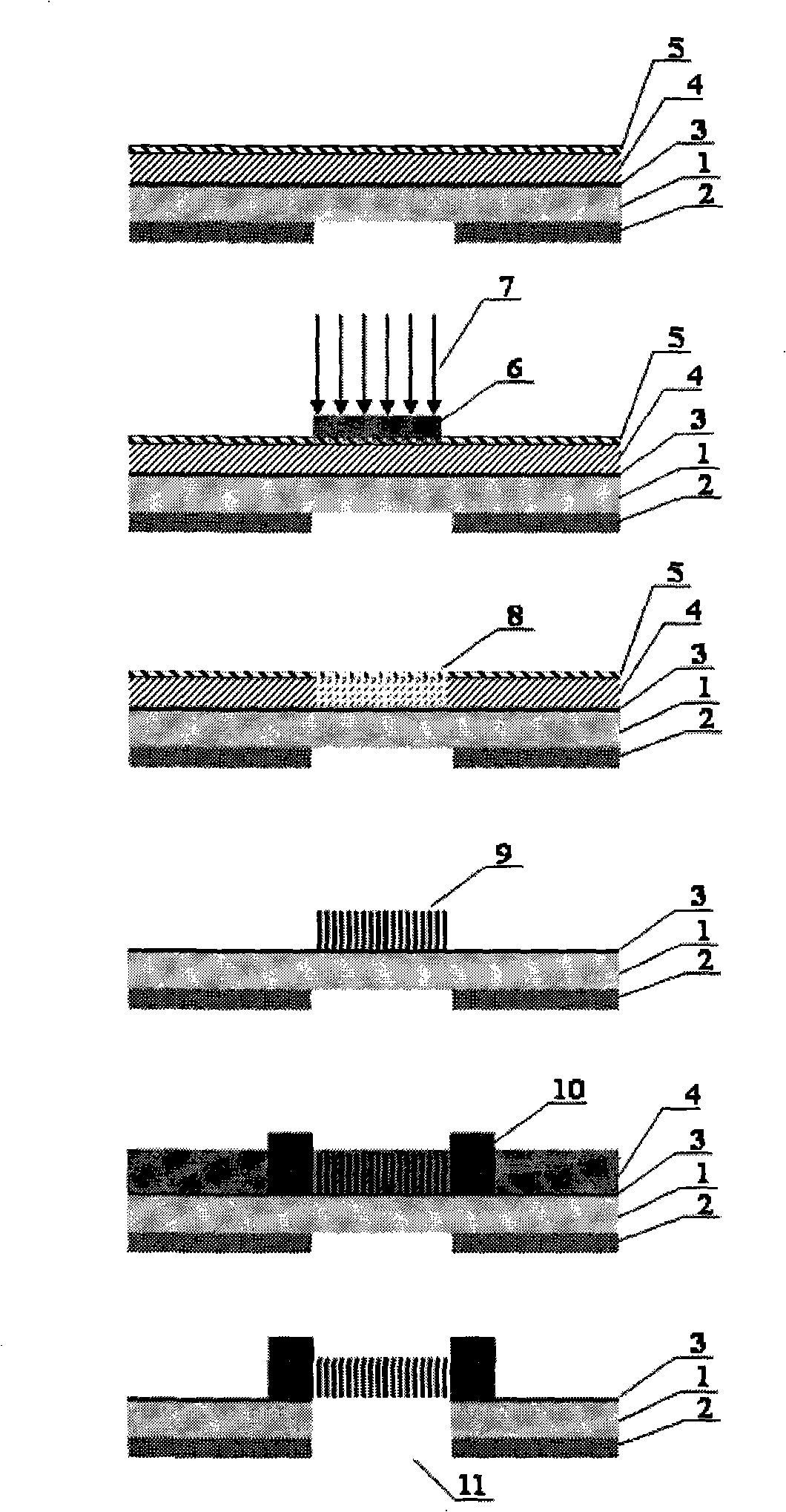

[0050] Example 1. Take the P-type (100) silicon substrate as an example:

[0051] (1) Select a P-type (100) silicon substrate 1 with an appropriate size and a clean surface as the substrate material for preparing the grating;

[0052] (2) Spin-coat SU-8 photoresist negative resist 2 on the back side of the silicon substrate, and use contact photolithography exposure and development process to form a window consistent with the light flux aperture on the photoresist to expose the substrate material;

[0053] (3) adopt electron beam evaporation process to vapor-deposit 5nm thick Cr on the front of silicon substrate, vapor-deposit 15nm thick Au metal thin film 3; Cr layer and Au layer constitute metal thin film together, and Cr layer contacts with substrate, The Au layer is in contact with the Cr layer to increase the adhesion between Au and the substrate;

[0054] (4) Spin-coat the transfer layer 4 (NXR-3000, Nanonex, USA) and the UV-cured imprint layer 5 (NXR-2000) of the nanoi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com