Thermal sublimation photographic paper electrostatic resistance coatings

An antistatic and sublimation technology, applied in the direction of photosensitive material substrate/auxiliary layer, etc., can solve the problems of reducing surface resistance, polluting image receiving layer, and deterioration of adhesive fastness, so as to ensure effectiveness, permanence, and excellent The effect of antistatic performance and good adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

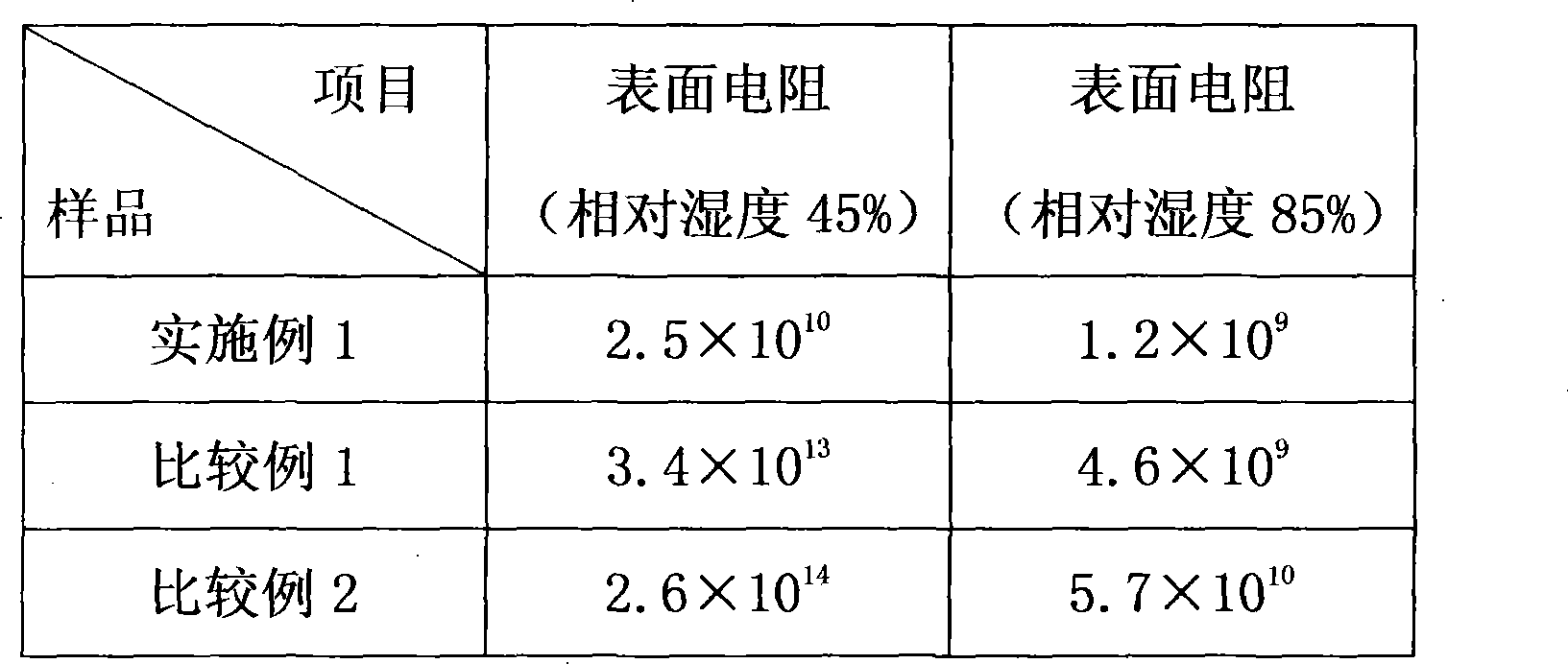

Examples

Embodiment 1

[0012] permanent antistatic agent 5

[0013] Auxiliary antistatic agent 12

[0014] Titanate coupling agent 0.6

[0015] Dispersant 0.2

[0016] Acrylic 15

[0017] Brightener 0.005

[0018] Leveling agent 0.03

[0019] Toluene 30

[0020] Butyl acetate 28

[0021] Auxiliary antistatic agent TiO 2 Add the conductive powder into the high-speed disperser, add the dispersant (Disponer912) and titanate coupling agent, stir to carry out the coupling reaction, and then disperse at high speed to make a dispersion liquid. Add this dispersion into the acrylic resin solution and stir well, add permanent antistatic agent (IRGASTAT P18 from Ciba), whitening agent and leveling agent to make antistatic coating liquid. The coating solution was coated on a polyethylene terephthalate (PET) film with a metering rod, placed in an oven, and dried at 100° C. for 3 minutes to form an antistatic coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com