Method for production of water absorbing agent

一种生产方法、吸水剂的技术,应用在生产吸水剂领域,能够解决吸水性树脂表面改性不均匀等问题,达到缩短处理时间、降低原材料成本、降低能量消耗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

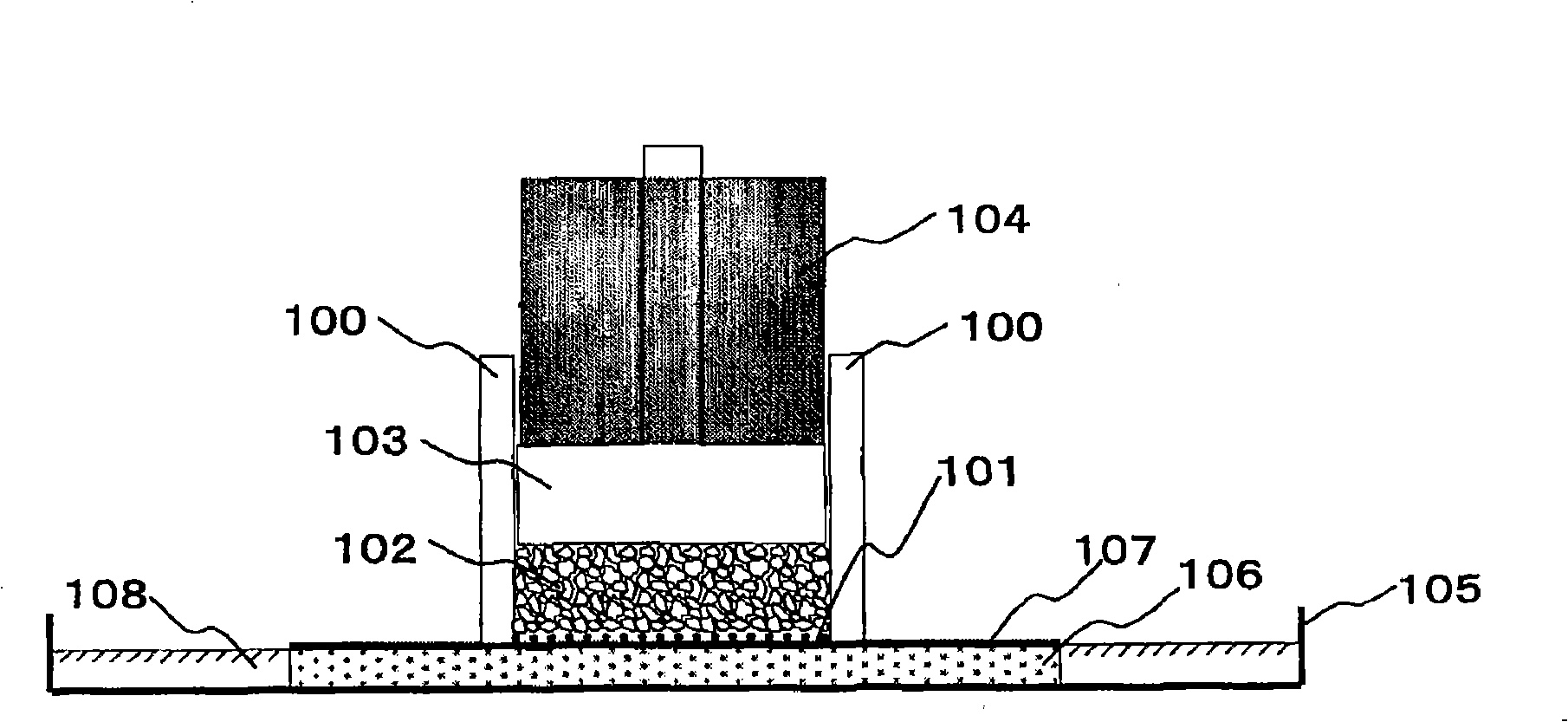

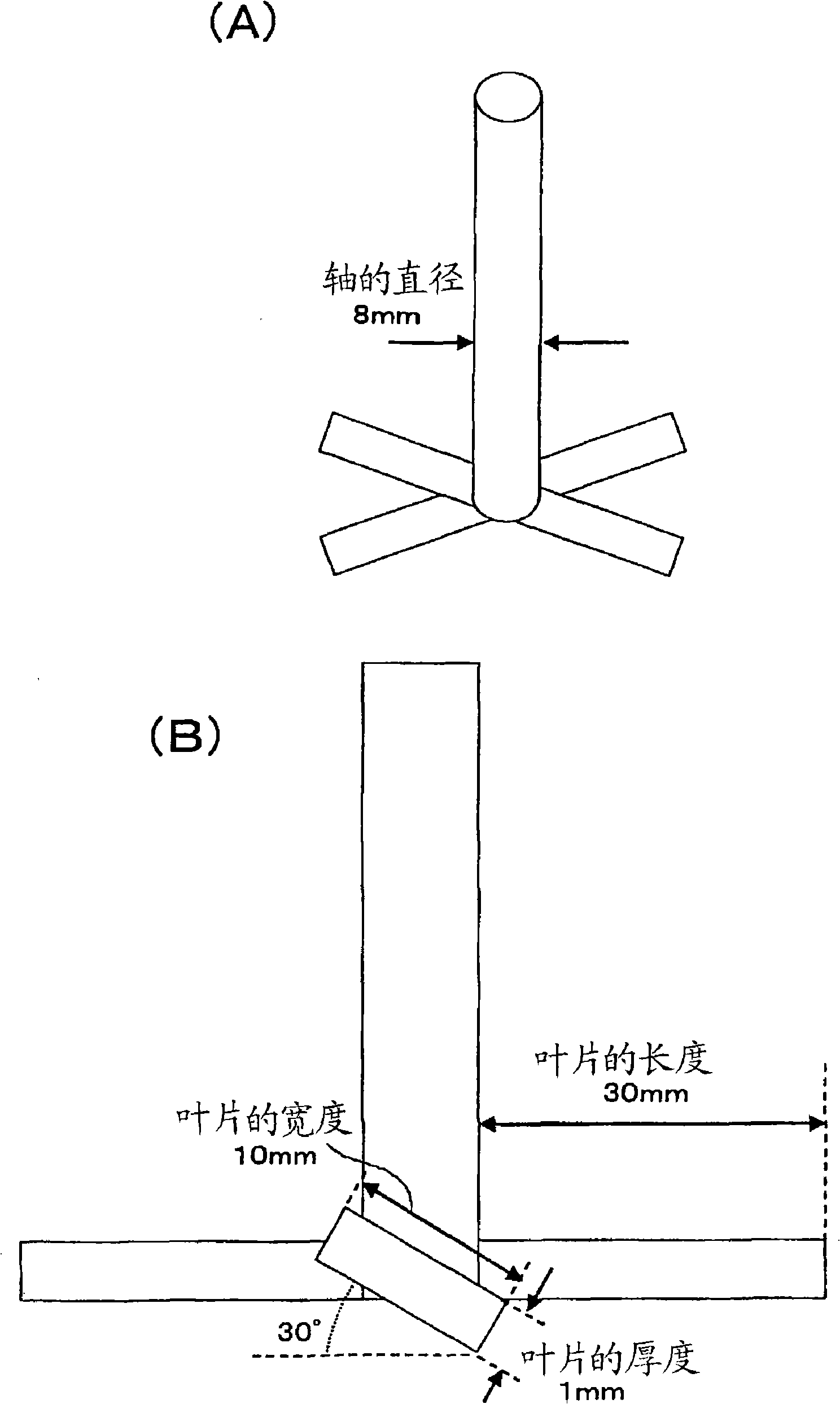

[0109] Now, the present invention will be described more specifically below with reference to working examples and comparative examples. The invention is not limited to these working examples. Incidentally, various properties of the water-absorbent resin described here were measured by the following methods. All operations described here were performed at room temperature (20-25°C) and humidity 50RH%, unless specific conditions were cited.

[0110] (1) Centrifuge holding capacity (abbreviated as CRC)

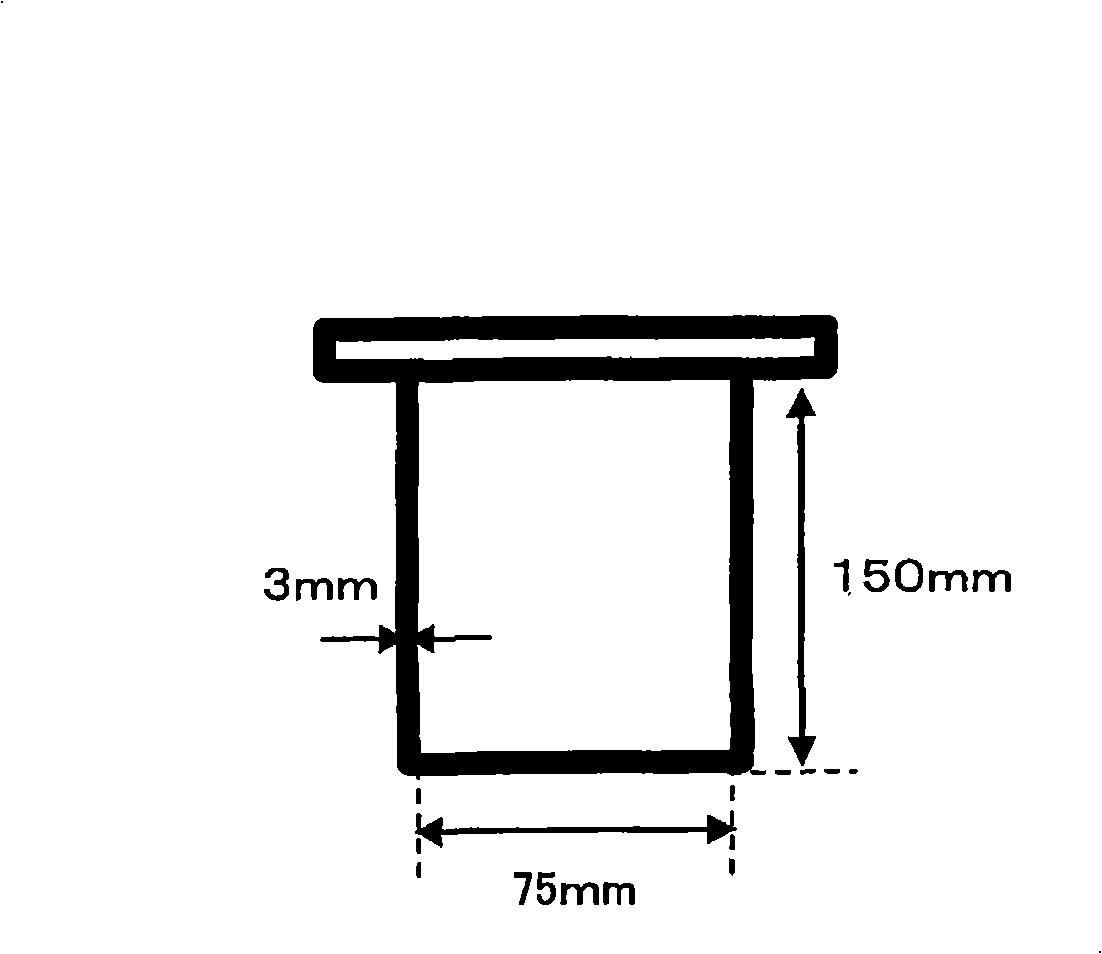

[0111] The centrifuge retention capacity (CRC) indicates the absorption capacity exhibited by a given sample after standing without pressure in a 0.90% by weight aqueous solution of saline for 30 minutes. A bag (85 mm x 60 mm) made of a nonwoven fabric (manufactured by NangokuPulp Kogyo K.K., sold under the trade name "Heatlon Paper, Type GSP-22") is uniformly filled with 0.200 g of a given water-absorbent resin or water-absorbent, heated Seal and immerse in a large excess (t...

reference example 1

[0138] 8.55 g of polyethylene glycol diacrylate was dissolved in 5446 g of an aqueous sodium acrylate solution having a monomer concentration of 39% by weight and a neutralization rate of 60 mol% was used to prepare a reaction solution. Then, the reaction solution was deaerated under nitrogen atmosphere for 30 minutes. When 20.1 g of a 10% by weight aqueous solution of sodium persulfate and 25.2 g of a 0.1% by weight aqueous solution of L-ascorbic acid were subsequently added and the reaction solution was kept stirring, polymerization was initiated within about 1 minute of the addition of the aqueous solutions. Then, polymerization was carried out at 20-95° C. while continuously pulverizing the formed gel. 30 minutes after the start of the polymerization, the hydrogel-like crosslinked polymer was taken out. The hydrogel-like polymer is produced in the form of particles finely divided into particles not exceeding about 5 mm in diameter. The finely divided hydraulic cross-lin...

reference example 2

[0141] In a reaction vessel formed by fitting a stopper to a jacketed stainless steel double-arm type kneader provided with two sigma-type blades and having an inner volume of 10 liters, 7.95 g of polyethylene glycol diacrylate was dissolved in a A reaction solution was prepared in 5438 g of an aqueous sodium acrylate solution having a monomer concentration of 39% by weight and a neutralization rate of 70 mol%. Then, the reaction solution was degassed for 30 minutes under nitrogen atmosphere. When 29.43 g of a 10% by weight aqueous solution of sodium persulfate and 24.53 g of a 0.1% by weight aqueous solution of L-ascorbic acid were subsequently added and the reaction solution was kept stirring, polymerization was initiated within about 1 minute of the addition of the aqueous solutions. Then, polymerization was carried out at 20-95° C. while continuously pulverizing the formed gel. 30 minutes after the start of the polymerization, the hydrogel-like crosslinked polymer was tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com