Method for preparing Mg2Si powder by semi-solid-state reaction

A semi-solid and powder technology, applied in the direction of metal silicide, etc., can solve the problems of long time, many impurities, low efficiency, etc., and achieve the effect of short reaction time, high purity and light pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) raw material Mg powder (99.9%) and Si (99.99%) powder are mixed by the weight percentage of 1.817: 1, in the vacuum glove box that has been filled with an atmospheric pressure high-purity argon, pack into ball mill jar, ball-to-material ratio is 48:1. Then on the planetary ball mill with 255 rpm ball milling for 1 hour;

[0030] (2) Take the powder out of the ball mill tank in the glove box, put it into a boron nitride crucible, and then put it into a stainless steel airtight tank as a whole for sealing.

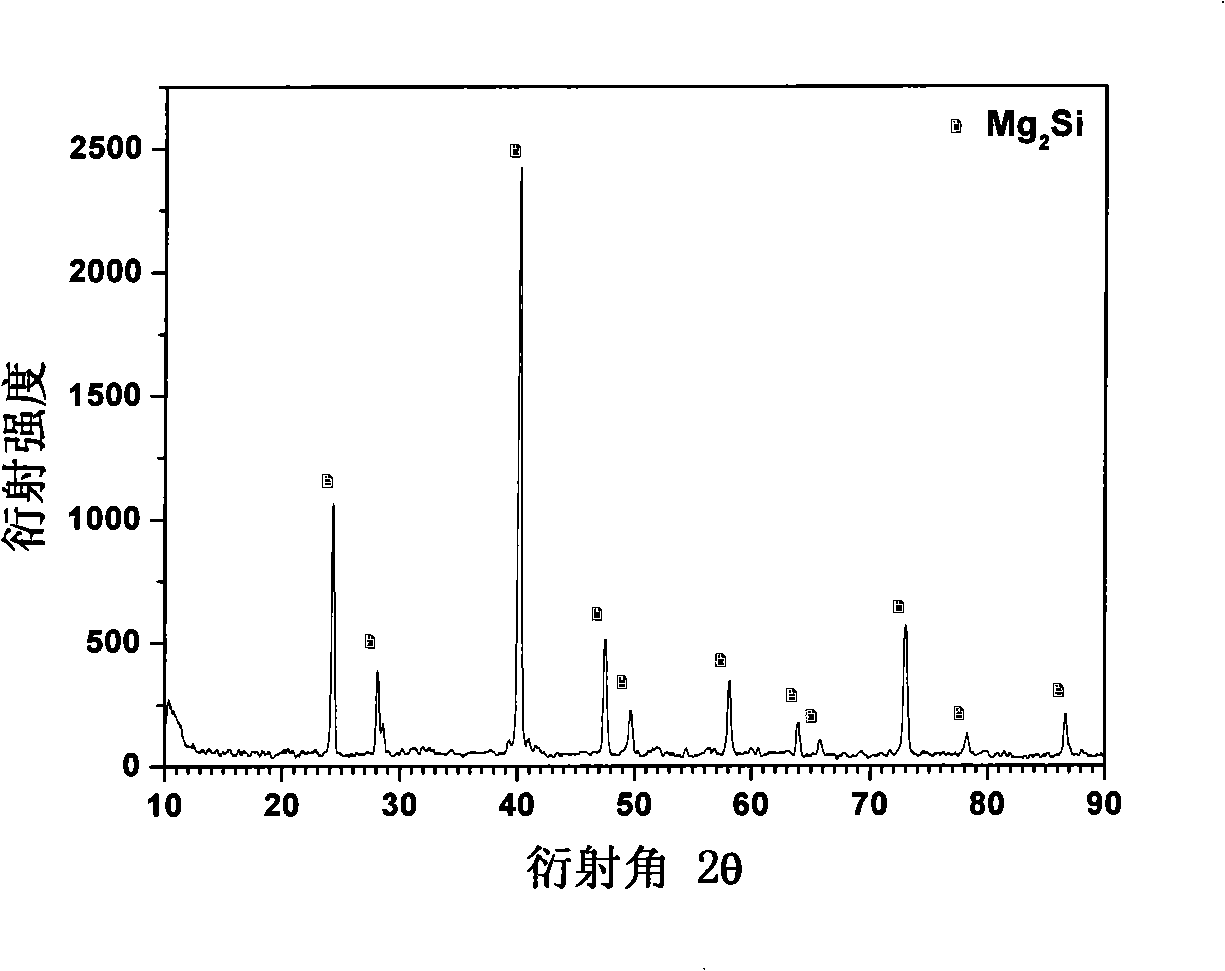

[0031] (3) Put the sealed jar into a box furnace heated to 700° C. to keep warm for 1 hour, then take it out and quickly cool it in the air. Open the can to get Mg 2 Si powder. Such as figure 1 As shown, the X-ray diffraction results show that there is no residual Mg or Si, and the original mixed powder has completely transformed into a single-phase Mg 2 Si. It is identified by chemical analysis that the impurity Fe content is lower than 0.01wt%.

Embodiment 2

[0033] (1) Prepare raw material powder as described in Example 1 (1). Then on the planetary ball mill with 255 rpm ball milling for 1.5 hours;

[0034] (2) prepare the Mg that obtains complete reaction as described in embodiment 1 (2) and (3) 2 Si powder, impurity Fe content is lower than 0.022wt%.

Embodiment 3

[0036] (1) Prepare raw material powder as described in Example 1 (1). Then on planetary ball mill with 255 rev / min rotating speed ball mills 2 hours;

[0037] (2) prepare the Mg that obtains complete reaction as described in embodiment 1 (2) and (3) 2 Si powder, impurity Fe content is lower than 0.031wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com