Generating method for crassitude carbon nano-tube and carbon nano-fibre in carbon composite refractory material

A technology of carbon nanofibers and refractory materials, which is applied in the field of generation of thick carbon nanotubes and carbon nanofibers in carbon composite refractory materials. Good, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

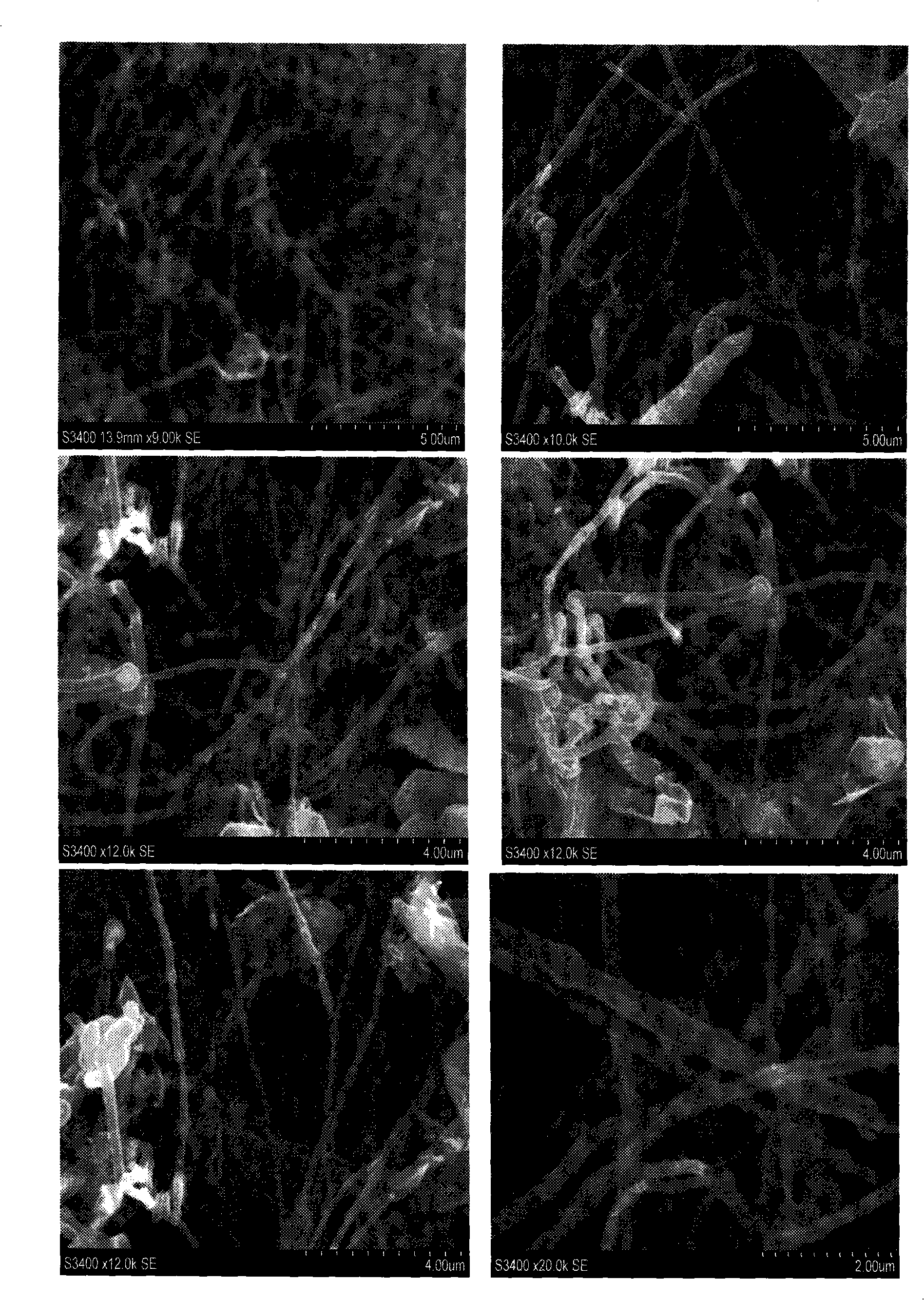

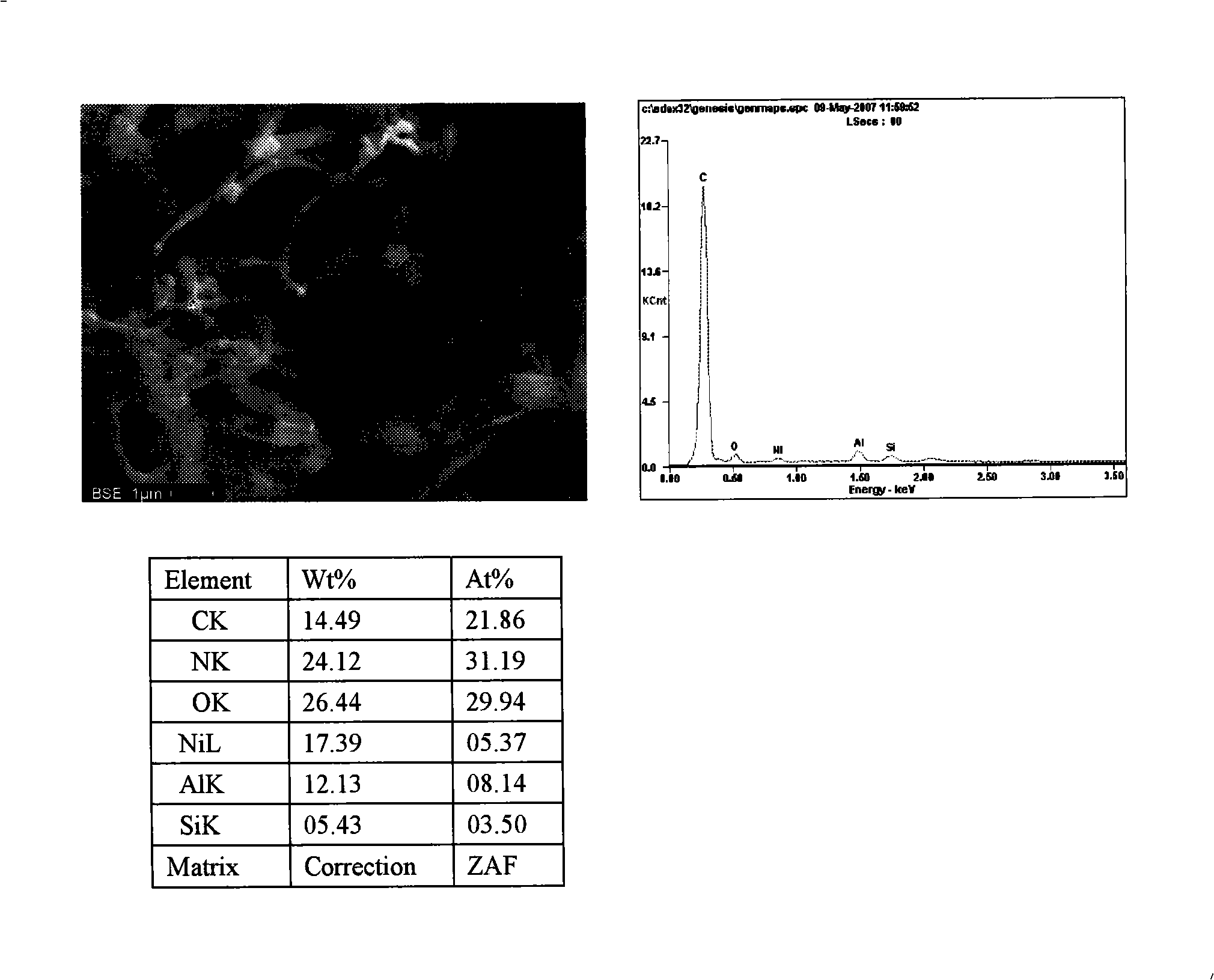

Image

Examples

Embodiment 1

[0015] 1) According to the physical and chemical indicators shown in Table 1, select sintered tabular alumina, α-Al 2 o 3 , graphite, metal silicon powder, phenolic resin, and nickel nitrate; according to the mixing ratio of various materials shown in Table 2, respectively weigh 380g of tabular alumina with a particle size of 1.0-0mm, 330g of tabular alumina with a particle size of 2 o 3 Powder 30g, flake graphite 240g, metal silicon powder 20g, phenolic resin 60g spare;

[0016] 2) Weigh 5 grams of nickel nitrate and add 45 grams of distilled water to prepare a solution with a concentration of 10%, then add it to the 330 g of plate-shaped corundum powder with a particle size of 2 o 3 Powder, 20g metal silicon powder mixed for later use;

[0017] 3) After heating 60g of phenolic resin in a water bath at 80°C for 15 minutes, add half of it to 380g of plate-shaped corundum with a particle size of 1.0-0mm weighed in step 1). After mixing for 5 minutes, add 240g of flake graphi...

Embodiment 2

[0020] 1) According to the physical and chemical indicators shown in Table 1, select sintered tabular alumina, α-Al 2 o 3 , graphite, metal silicon powder, phenolic resin, and nickel nitrate; according to the mixing ratio of various materials shown in Table 2, we weighed 380g of tabular alumina with a particle size of 1.0-0mm, 330g of tabular alumina with a particle size of 2 o 3 Powder 30g, flake graphite 240g, metal silicon powder 20g, phenolic resin 60g spare;

[0021] 2) Weigh 10 grams of nickel nitrate and add 90 grams of distilled water to prepare a solution with a concentration of 10%, and then add it to the 330 g of platy corundum powder with a particle size of 2 o 3 Powder, 20g metal silicon powder are mixed for later use;

[0022] 3) After heating 60g of phenolic resin in a water bath at 80°C for 15 minutes, add half of it to 380g of plate-shaped corundum with a particle size of 1.0-0mm weighed in step 1). After mixing for 5 minutes, add 240g of flake graphite wei...

Embodiment 3

[0025] 1) According to the physical and chemical indicators shown in Table 1, select sintered tabular alumina, α-Al 2 o 3 , graphite, metal silicon powder, phenolic resin, and nickel nitrate; according to the mixing ratio of various materials shown in Table 2, we weighed 380g of tabular alumina with a particle size of 1.0-0mm, 330g of tabular alumina with a particle size of 2 o 3 Powder 30g, flake graphite 240g, metal silicon powder 20g, phenolic resin 60g spare;

[0026] 2) Weigh 30 grams of nickel nitrate and add 270 grams of distilled water to prepare a solution with a concentration of 10%, then add it to the 330 g of platy corundum with a particle size of 2 o 3 Powder, 20g metal silicon powder are mixed for later use;

[0027] 3) After heating 60g of phenolic resin in a water bath at 80°C for 15 minutes, add half of it to 380g of plate-shaped corundum with a particle size of 1.0-0mm weighed in step 1). After mixing for 5 minutes, add 240g of flake graphite weighed in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com