Method for preparing high purity solid cyanoacetic acid

A cyanoacetic acid and high-purity technology, applied in the field of preparation of high-purity cyanoacetic acid, can solve problems such as application limitation, and achieve the effects of easy recovery and reuse, simple process and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

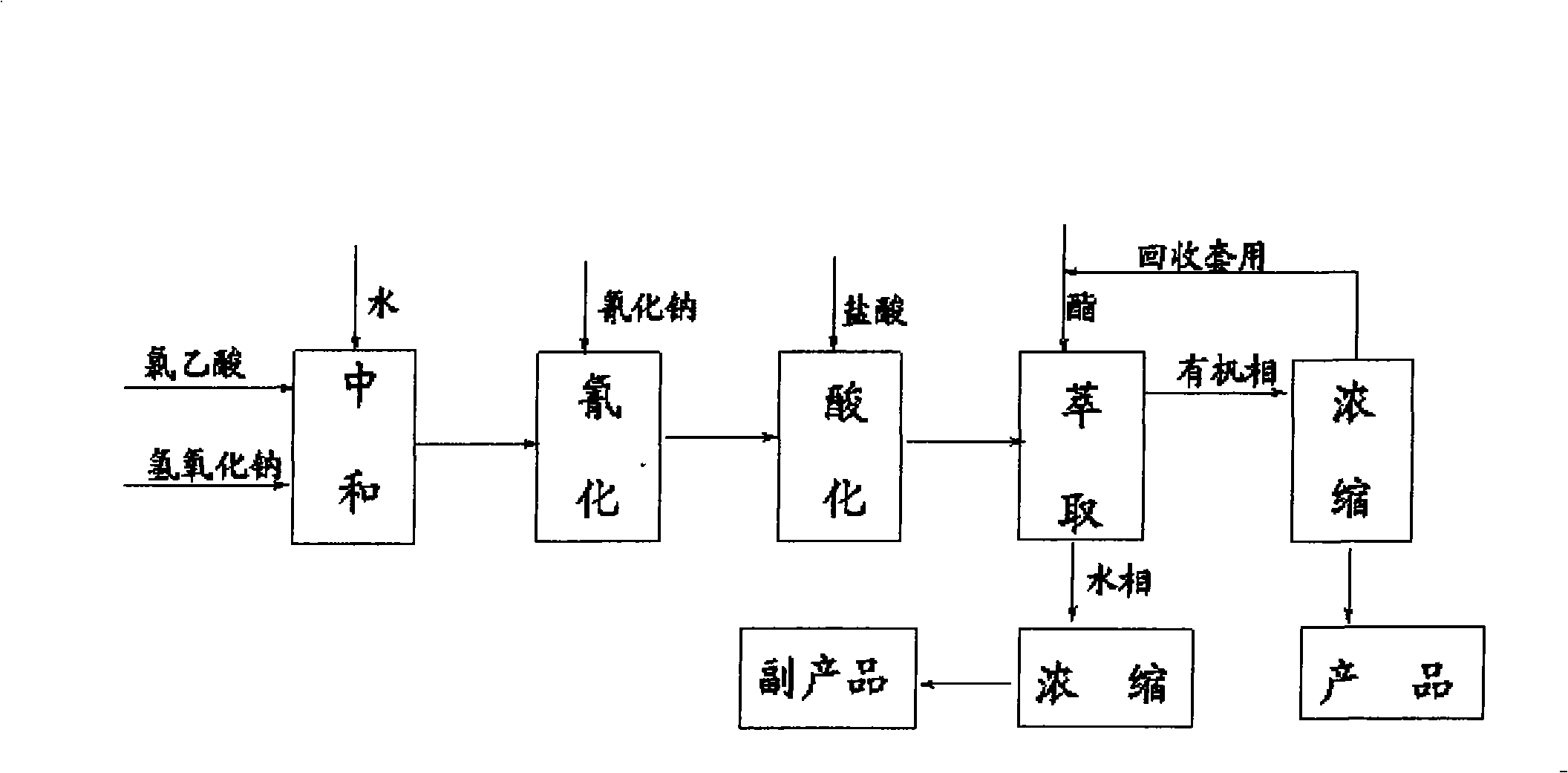

Image

Examples

Embodiment 1

[0018] (1) Preparation of cyanoacetic acid aqueous solution:

[0019] Add sodium hydroxide to chloroacetic acid for neutralization, add sodium cyanide for cyanation to obtain sodium cyanoacetate aqueous solution, then add hydrochloric acid for neutralization to obtain a mixed solution of cyanoacetic acid and sodium chloride:

[0020] ClCH 2 COOH+NaOH→ClCH 2 COONa +H 2 o

[0021] ClCH 2 COONa +NaCN→CNCH 2 COONa+NaCl

[0022] CNCH 2 COONa+HCl→CNCH 2 COOH+NaCl

[0023] (2) At 50°C, extract the mixed solution prepared in step (1) with ethyl formate, the volume ratio of the mixed solution prepared in said step (1) to ethyl formate is 1:3, and the number of extractions is 5 times , each extraction time is 10min;

[0024] (3) Concentrating the extract by evaporating under reduced pressure to obtain solid cyanoacetic acid with a content of more than 98%, while reclaiming the extractant ethyl formate;

[0025] (4) Recovery of salt

[0026] Extract the inorganic salts in the...

Embodiment 2

[0028] (1) Sodium hydroxide aqueous solution is added in the chloroacetic acid, neutralizes to neutrality below 45 ℃, obtains sodium chloroacetate solution; The neutralization solution is added in the sodium cyanide aqueous solution that mass percent concentration is 30%, react Control the temperature at 105-115°C and keep it warm for 30 minutes to obtain an aqueous solution of sodium cyanoacetate; after cooling down to below 50°C, add hydrochloric acid to neutralize to obtain a mixed solution of cyanoacetic acid and sodium chloride, and measure the content of cyanoacetic acid; (this step It is a traditional process, and a mixed solution of cyanoacetic acid and sodium chloride can also be obtained under other conditions)

[0029] (2) Take the mixed solution of cyanoacetic acid and sodium chloride as the water phase (W), ethyl acetate (O) as the oil phase, and extract with intermittent stirring, in a there-necked flask equipped with a stirrer, a thermometer and a condenser Add ...

Embodiment 3

[0032] (1) with embodiment 2;

[0033] (2) Compared with O / W=3, the ester solvent is propyl formate, which is extracted by intermittent stirring, the extraction temperature is 50°C, and the extraction time is 10 minutes;

[0034] (3) After phase separation, the organic phase was distilled under reduced pressure to obtain solid cyanoacetic acid, and the yield of one extraction of cyanoacetic acid was 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com