Gravure platemaking roll and its manufacturing method

A technology of gravure plate making and manufacturing method, applied in the directions of printing plate, printing plate preparation, ion implantation and plating, etc., can solve the problems of poor lubricity, deterioration, unsharp cutting of the squeegee, etc. Excellent strength, the effect of omitting the chrome plating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

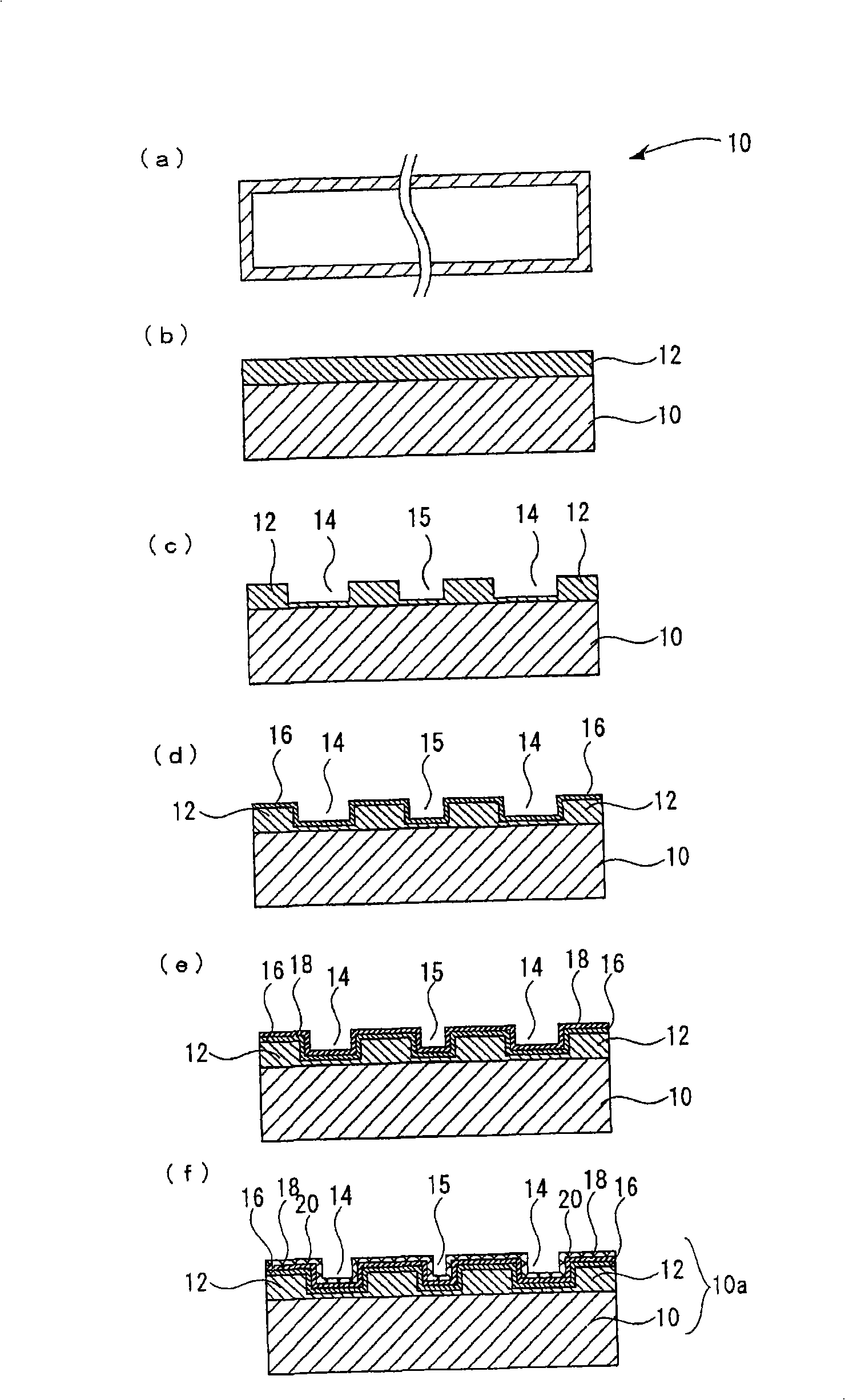

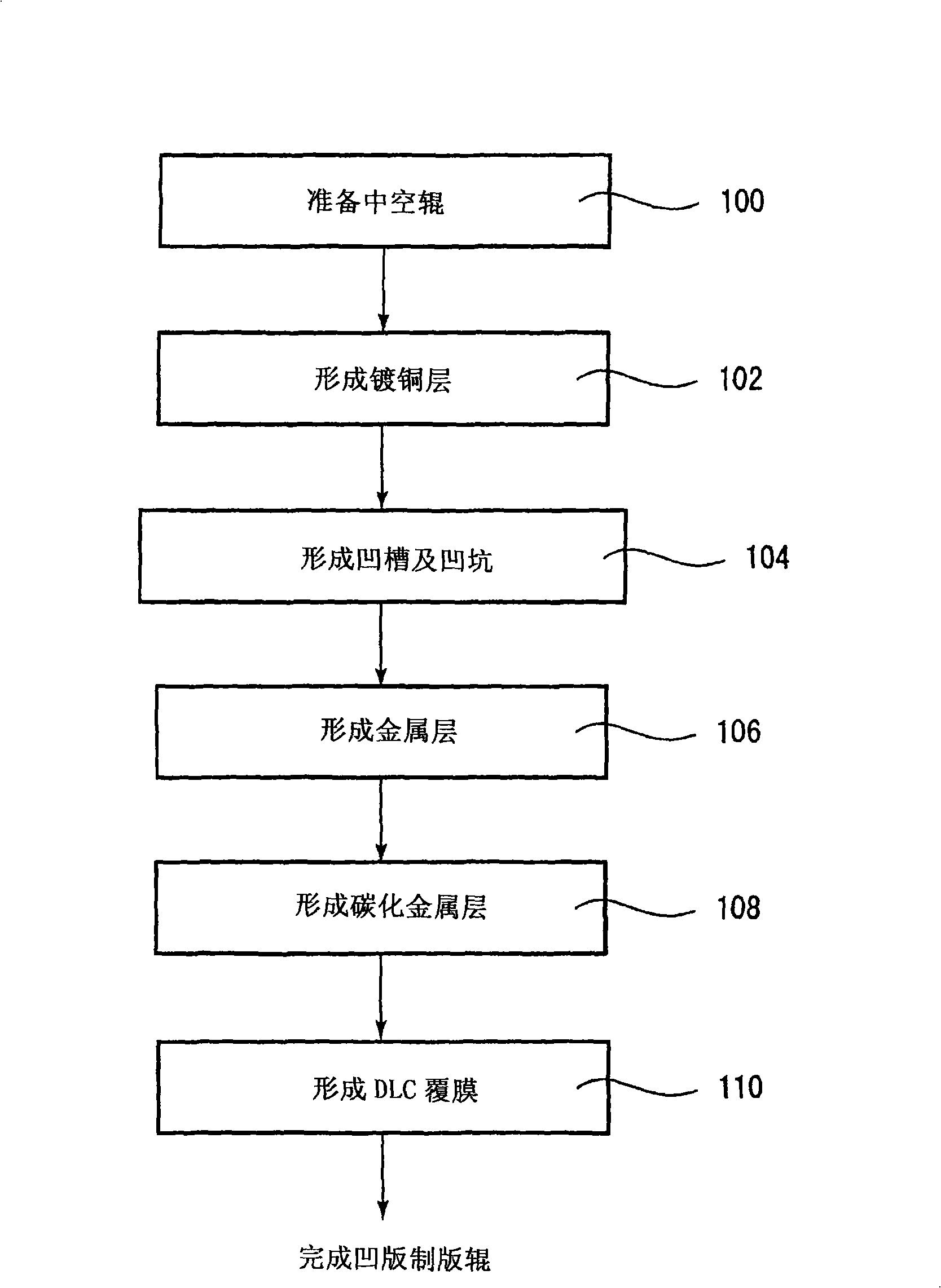

[0062] Install a gravure cylinder (aluminum hollow roll) with a circumference of 600 mm and a surface length of 1100 mm in the plating tank, and use an automatic sliding device based on a computer system to move the anode chamber to the hollow roll to a distance of 20 mm, so that the plating solution overflows and submerges the hollow roll. / dm2, 6.0V to form a copper plating layer of 80μm. The plating time was 20 minutes, no peeling etc. occurred on the plating surface, and a uniform copper plating layer was obtained.

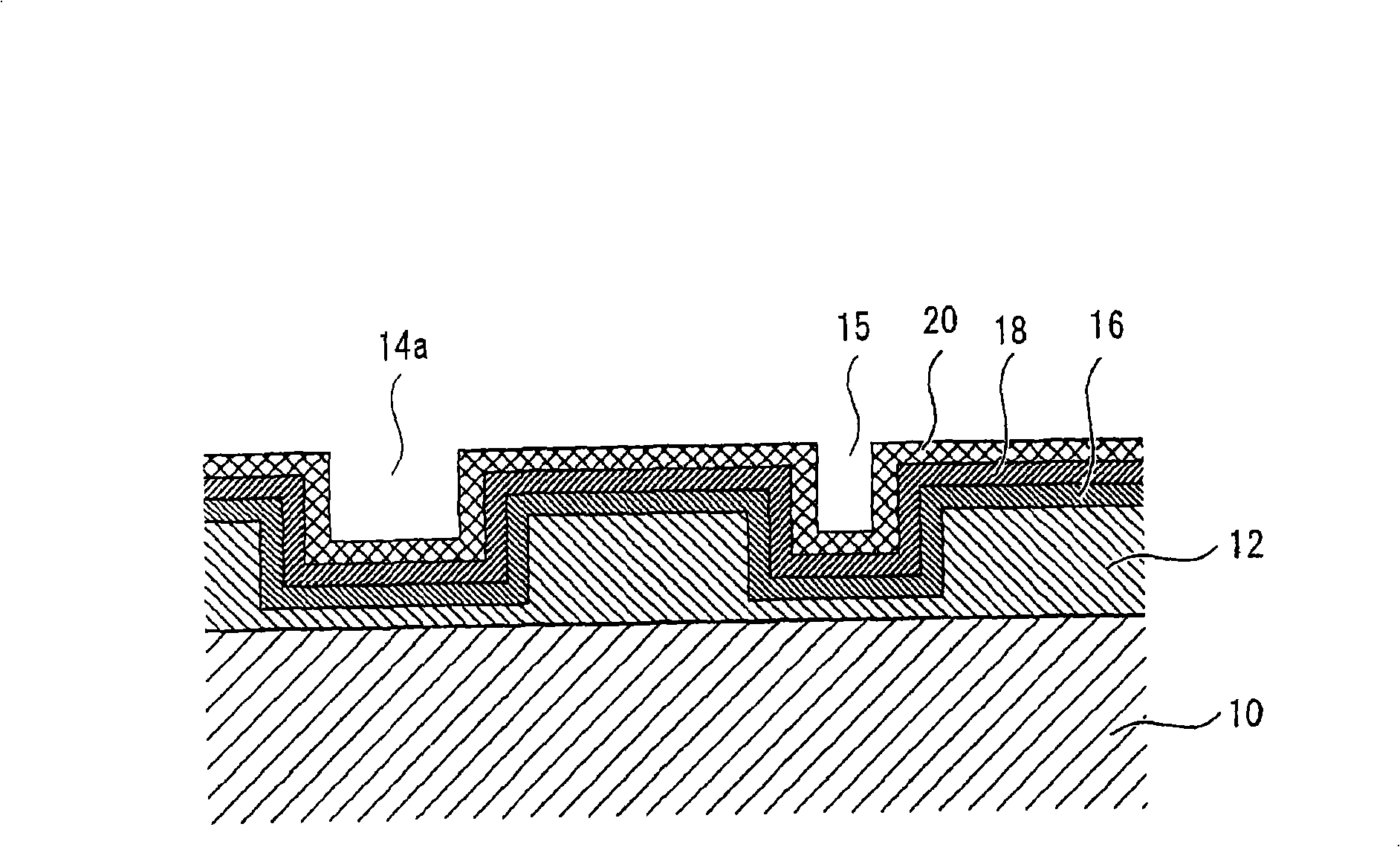

[0063] A photosensitive film is applied on the copper plating layer formed above, and the image is subjected to laser exposure, development, patterning, and a resist image is formed, followed by dry etching such as plasma etching, and the image composed of grooves is engraved and formed. pits, after which the resist image is removed to produce a hollow roll forming a printing plate.

[0064] A tungsten (W) layer was formed by sputtering on the copper plating ...

Embodiment 2

[0069]In the same manner as in Example 1, a hollow roll in which grooves and pits were formed was produced. For the above-mentioned hollow roll, except that the tungsten (W) sample was changed to a silicon (Si) sample, the gravure plate-making roll was processed in the same way as in Example 1, and after the printing test was similarly performed, it was obtained in the same way as in Example 1. A printed matter that does not generate fog in a part with slight scratches, or a part in which fine scratches are not applied with sandpaper also rarely generates fog and has good indexability. In these examples, it was confirmed that the diamond-like carbon (DLC) coating also has performance comparable to that of the conventional chromium layer and can be used as a substitute for the chromium layer sufficiently.

[0070] It was also confirmed that similar tests were performed using titanium (Ti) and chromium (Cr) as metal samples, and similar results were obtained.

Embodiment 3

[0072] A level of 0% to 100% is prepared as the board information before the board is formed. And, make the pattern that 2 laser beams are irradiated side by side along the roll peripheral direction, so that the unit exposure area as 3.5 μ m * 7.0 μ m is formed in the arrangement along the longitudinal direction of the roll surface with a pitch of 140 μ m, and the pitch in the roll peripheral direction is Randomly arrange within the range of 70 μm to 140 μm, and create digital version information in which the digital information of the screen screen screened through the screening program is superimposed on the above-mentioned grade.

[0073] Next, apply a positive-type photosensitive film made by Canada Creosity Technology Co., Ltd. on the mirror-finished copper-plated surface of the roller, so that the residual solvent is 2% or less, and then dry the photosensitive film, and then use the equipment that can be used at 1.8 The size of μm×7.0μm is used as a unit to output a lase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com