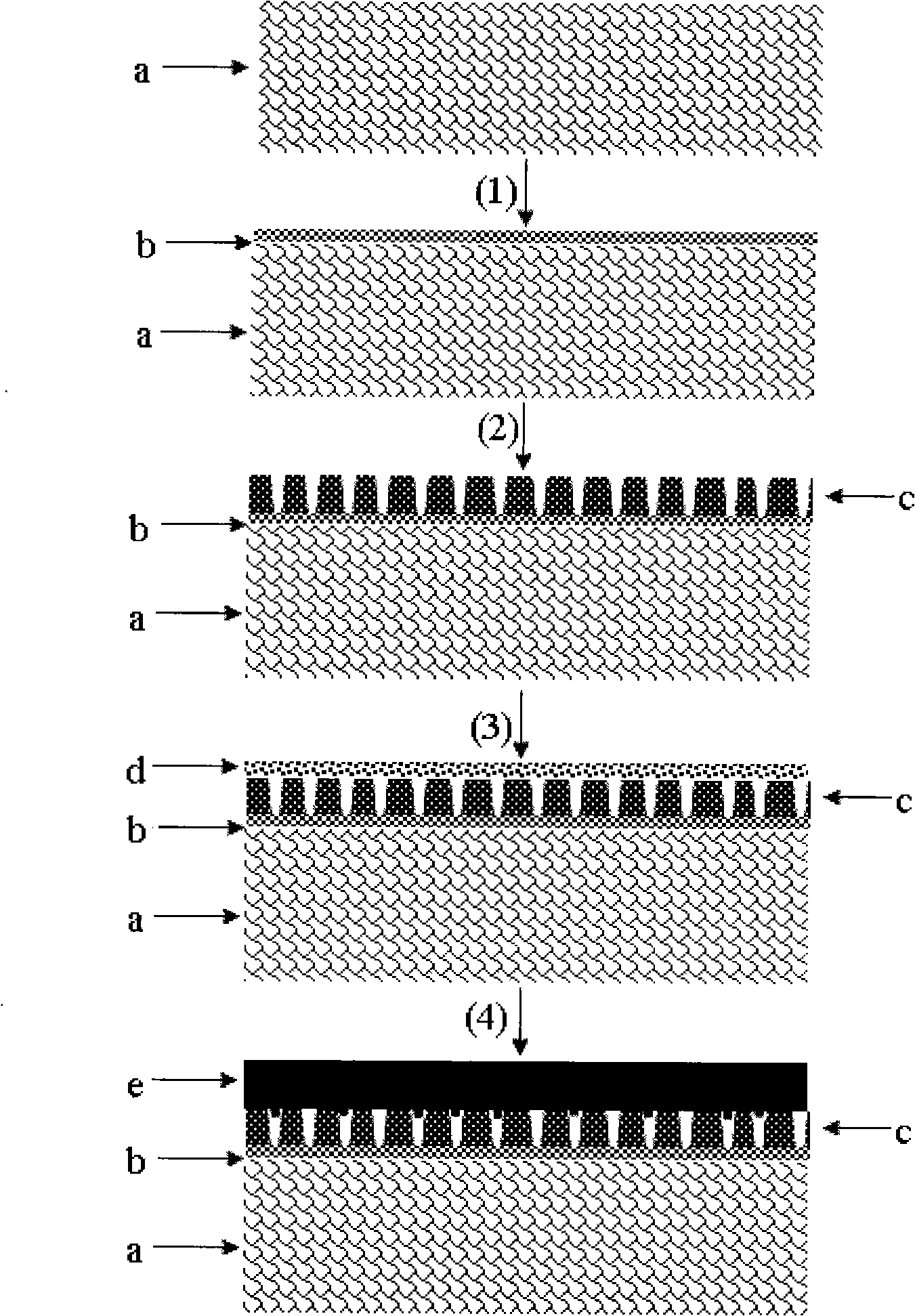

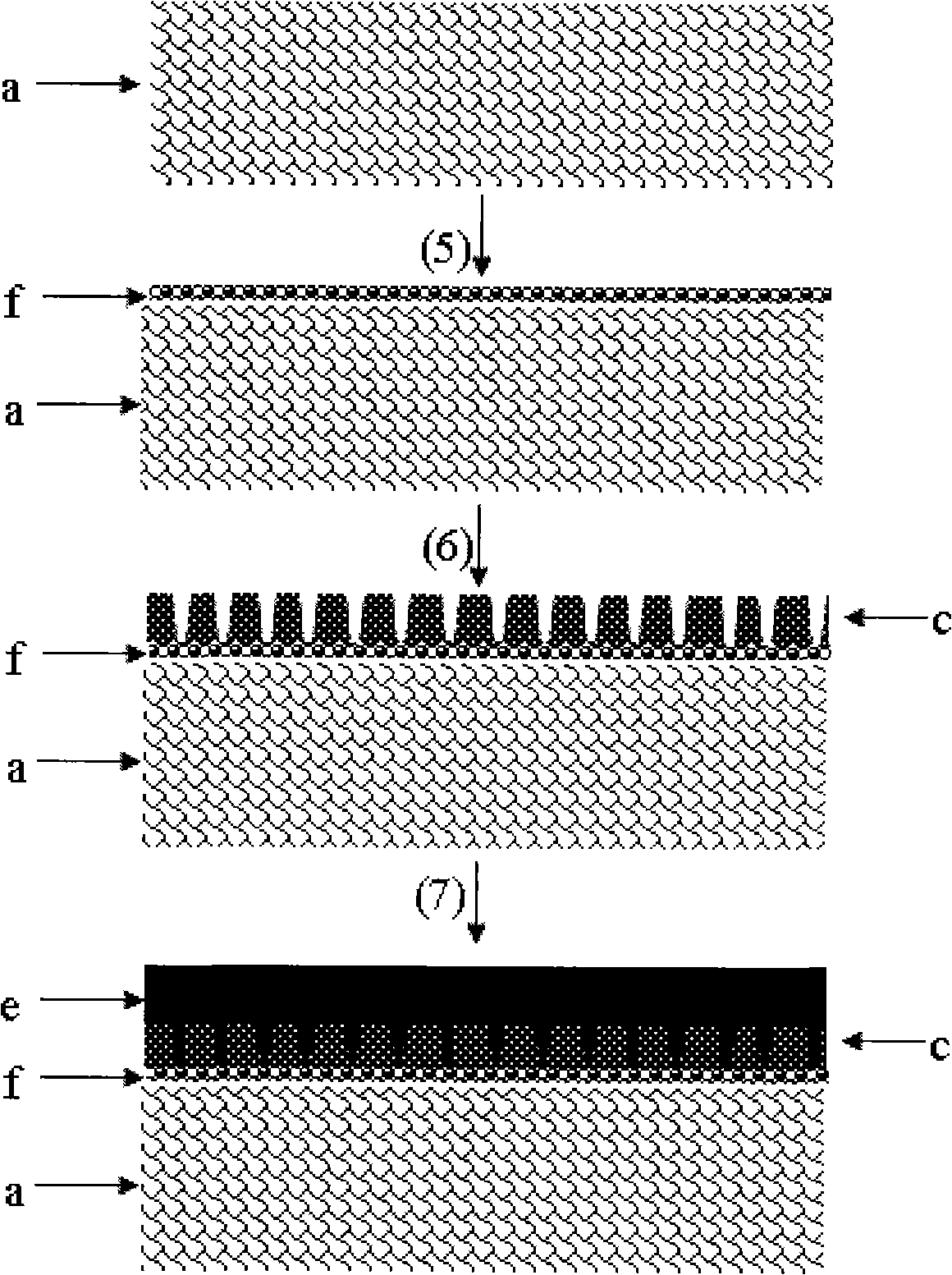

Method for preparing pd-zeolite compound film based on zeolite bed regulated macroporous support

A macroporous carrier and composite membrane technology, used in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of high temperature requirements in the activation process, violation of sustainable development, human and environmental hazards, etc. Low, practical, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Carrier pretreatment:

[0032] The porous support is α-Al with an average pore diameter of about 3 μm 2 o 3Ceramic carrier tube. Before the synthesis, the surface of the carrier was polished smooth with 600# and 800# sandpaper, and the carrier was cleaned to neutrality with dilute sodium hydroxide, dilute hydrochloric acid and deionized water under ultrasonic vibration, and then dried and roasted for use.

[0033] (2) Preparation of pure silicalite seed liquid and pre-coating seed crystal on the carrier surface:

[0034] Using tetrapropylammonium hydroxide (TPAOH), sodium hydroxide and deionized water as raw materials, according to SiO 2 :TPAOH:H 2 O=100:25:2700 molar ratio to prepare pure silicalite seed crystal synthesis precursor solution, stir at room temperature for 24 hours, pour into a stainless steel crystallization kettle with polytetrafluoroethylene lining, seal it and put it in an oven at 100°C, place Take it out after 16 hours, centrifuge the obtain...

Embodiment 2

[0040] (1) Carrier pretreatment: same as embodiment one.

[0041] (2) Preparation of palladium-containing pure silicalite seed crystals and pre-coating seed crystals on the carrier surface:

[0042] Pure silicon seed crystal preparation method is the same as embodiment one, according to PdCl 2 : pure silicon seed: PVA: H 2 The mass ratio of O=0.5:2:33:65 was used to prepare palladium-containing pure silicalite seed liquid, and stirred at room temperature for 6 hours. Put the pretreated carrier into the palladium-containing pure silica zeolite seed solution for 10 minutes by pulling method, then pull it out, dry it overnight at room temperature, and then put it into a muffle furnace at 500 ° C for 6 hours, and then raise and lower the temperature. The rate is: 1°C / min.

[0043] (3) Preparation of a palladium-containing zeolite layer carrier on the surface of the carrier: same as in Example 1.

[0044] (4) Activation of Pd-containing zeolite layer carrier and preparation of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com