Mach-zehnder type silicon optical waveguide switch based on narrow slit wave guide

A slit waveguide and waveguide switch technology, which is applied in the field of Mach-Zehnder type silicon optical waveguide switches, can solve the problems of limited application range, large absorption loss, and low extinction ratio, and achieve improved modulation efficiency, shortened pitch, and structural size compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

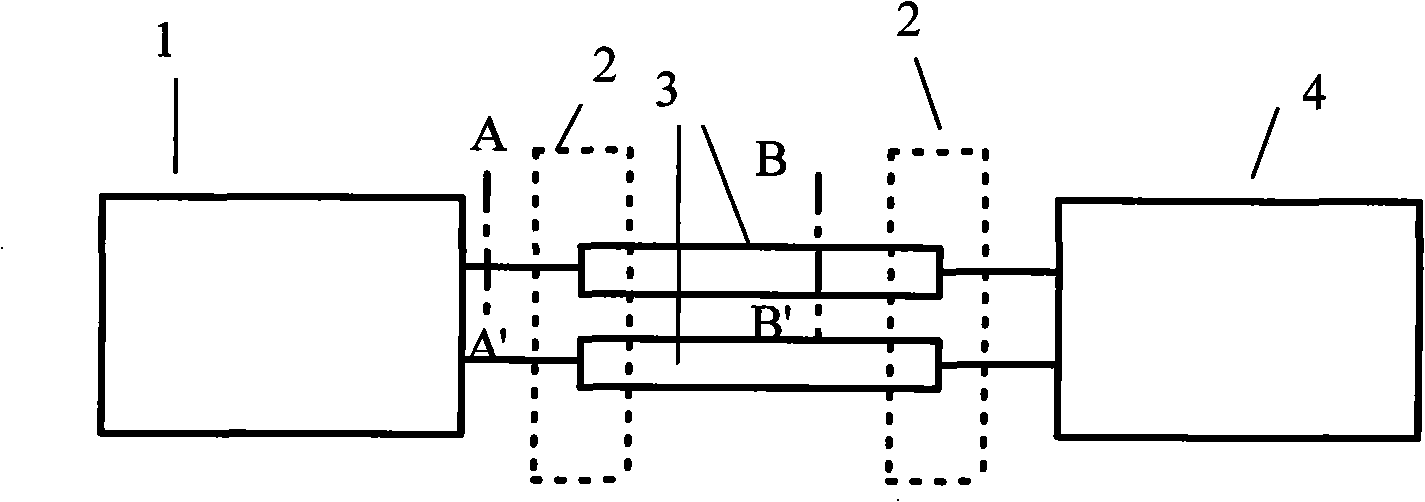

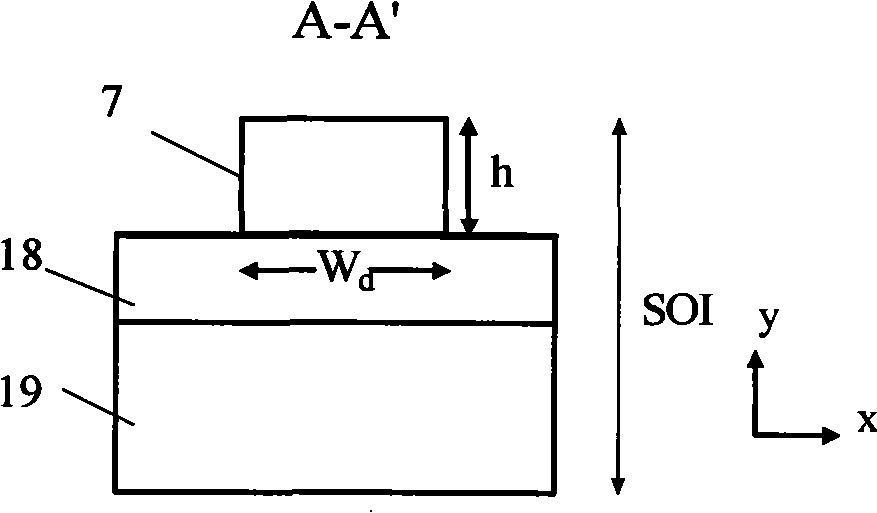

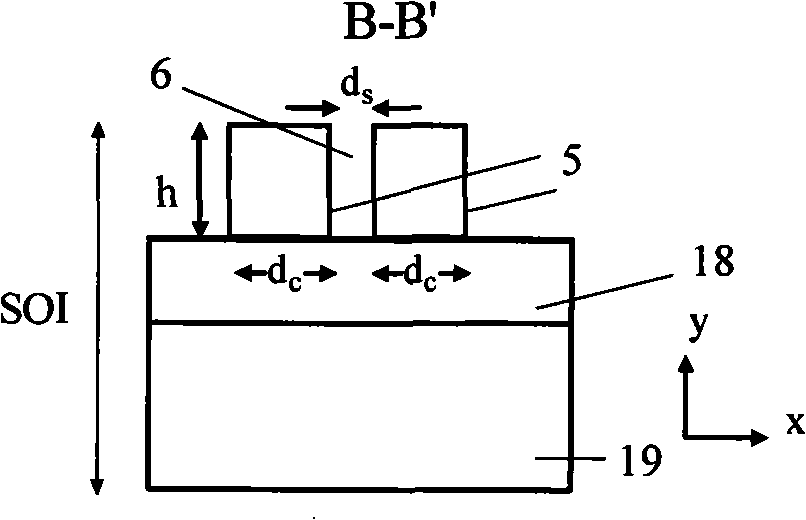

[0031] see Image 6 As shown, a 1×2 optical switch composed of a Y branch and an X structure is used. Take the SOI wafer with the top silicon thickness of 500 nanometers and the silicon dioxide buffer layer 18 thickness of 2 microns, thermally oxidize a layer of silicon dioxide on the top layer as a mask, and use the E-beam direct writing method to etch the device structure. . It includes a Y branch 10 for demultiplexing, a 9-mode spot conversion structure 2 for a tapered gradient waveguide pair composed of two silicon waveguides, an interference arm 3 for the slot waveguide structure, and an X junction 11 for combining waves. The electro-optical polymer DR1 / PMMA was covered by spin coating as the upper cladding layer and filled into the slits of the interference arms. The silicon waveguides 5 on both sides of the slit serve directly as electrodes.

[0032] When no phase modulation is applied, the guided wave is output from the wide-core waveguide 12; when one of the interf...

Embodiment 2

[0034] see Figure 7 shown, MMI-MZI type 1×2 optical switch. Take the SOI wafer with the top silicon thickness of 500 nanometers and the silicon dioxide buffer layer 18 thickness of 2 microns, thermally oxidize a layer of silicon dioxide on the top layer as a mask, and use the E-beam direct writing method to etch the device structure. . It includes a 1×2 MMI 16 for demultiplexing, an 8-mode spot conversion structure 2 consisting of a tapered gradient waveguide pair consisting of a single silicon waveguide, an interference arm 3 for a slot waveguide structure, and a 2×2 MMI 15 for combining waves. The device is immersed in liquid crystal, which acts as an upper cladding and fills the slits of the interference arms. The silicon waveguides 5 on both sides of the slit serve directly as electrodes.

[0035] When no modulation is applied, the light is output from the cross-state port. If modulation is applied to one of the phase-shift arms to produce a phase shift of π, the phas...

Embodiment 3

[0037] see Figure 8 As shown, the directional coupler constitutes a 2×2 optical switch. Take the SOI wafer with the top silicon thickness of 500 nanometers and the silicon dioxide buffer layer 18 thickness of 2 microns, thermally oxidize a layer of silicon dioxide on the top layer as a mask, and use the E-beam direct writing method to etch the device structure. . It includes a first directional coupler 17 that functions as a demultiplexer, a 9-mode spot conversion structure 2 composed of a tapered gradient waveguide pair composed of two silicon waveguides, an interference arm 3 of the slot waveguide structure, and a second wave-combining function. A directional coupler 11. The electro-optical polymer DR1 / PMMA was covered by spin coating as the upper cladding layer and filled into the slits of the interference arms. The silicon waveguides 5 on both sides of the slit serve directly as electrodes.

[0038] When unmodulated, the guided wave is output from the crossed state. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com