Extraction apparatus and method for producing hydrogen peroxide by anthraquinone method

A technology of hydrogen peroxide and extraction equipment, applied in chemical instruments and methods, liquid solution solvent extraction, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, etc., can solve anthraquinone work Problems such as high liquid viscosity and inability to enhance mass transfer can achieve the effect of saving equipment investment, avoiding amplification effect, and improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

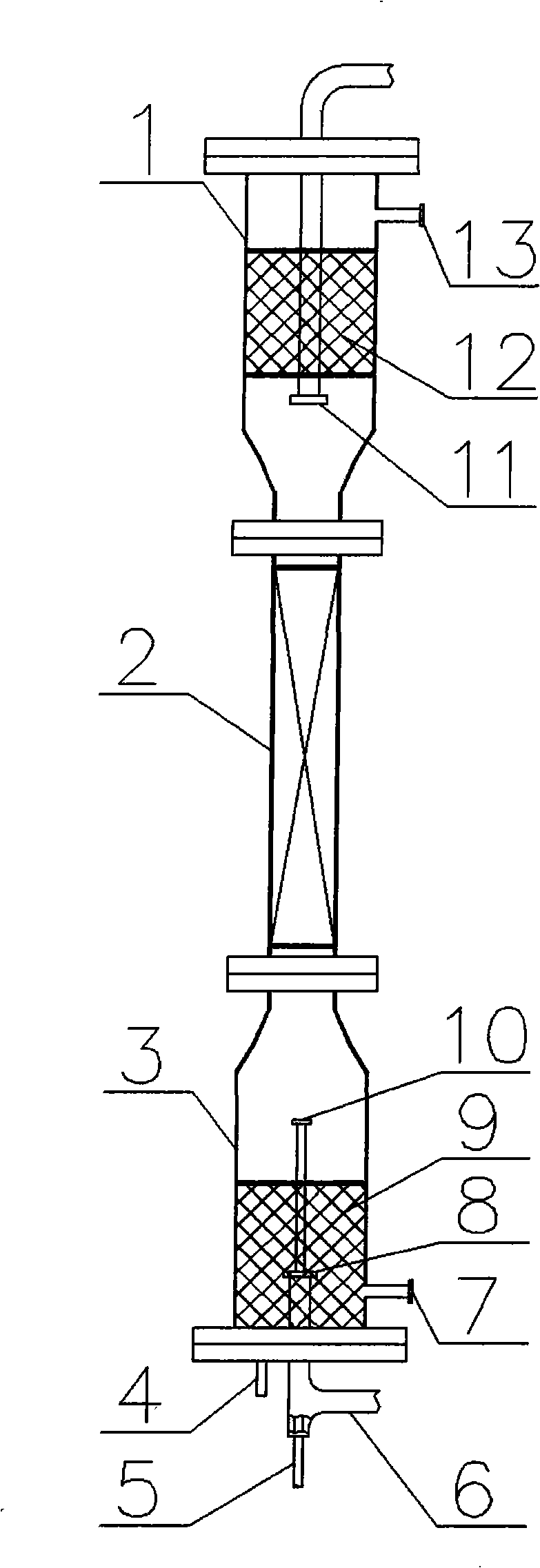

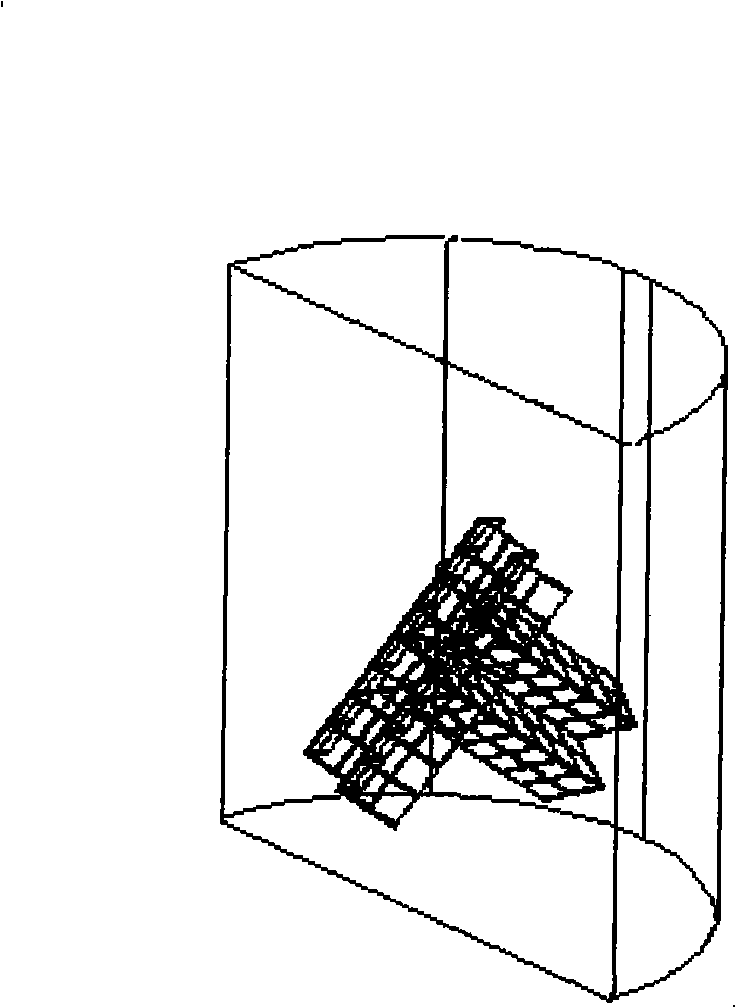

[0015] The present invention is described in detail below: a kind of special-purpose extraction equipment that is used for anthraquinone method to produce hydrogen peroxide, its structural schematic diagram is shown in figure 1 , the packed extraction tower has a total height of 3000mm; clarification section 1 has a height of 600mm and an inner diameter of 100mm, with a heavy phase distributor 11, a light phase anti-backmixing filler 12 and a light phase outlet 13, and the light phase outlet 13 is located 150mm away from the top of the tower. Distributor 11 adopts spray head type pressure type. Distributor spray head disk has a diameter of 40mm, and 26 small holes with a diameter of 1.5mm are evenly distributed. The support ring and the packing pressure ring are fixed on the tower body; below the clarification section 1 is the packing section 2, the height of the packing section is 1000mm, and the inner diameter is 50mm; the settlement section 3 is 600mm in height, and the inne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com