Transparent aquagel having antibacterial action and preparation thereof

A technology of antibacterial effect and hydrogel, which is applied in the field of transparent hydrogel and its preparation, can solve problems such as difficult realization, and achieve good biocompatibility, good development prospects, and simple synthesis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Add 100 parts by weight of acrylic acid and acrylamide into the reactor, start electromagnetic stirring; add NaOH aqueous solution dropwise for neutralization, and the neutralization degree is 75%. Wherein, the concentration of NaOH aqueous solution is 20wt%.

[0056] It should be noted that, in 100 parts by weight of acrylic acid and acrylamide, the weight ratio between acrylic acid and acrylamide is arbitrary. In Example 1, the weight ratio of acrylic acid and acrylamide is 1:1.

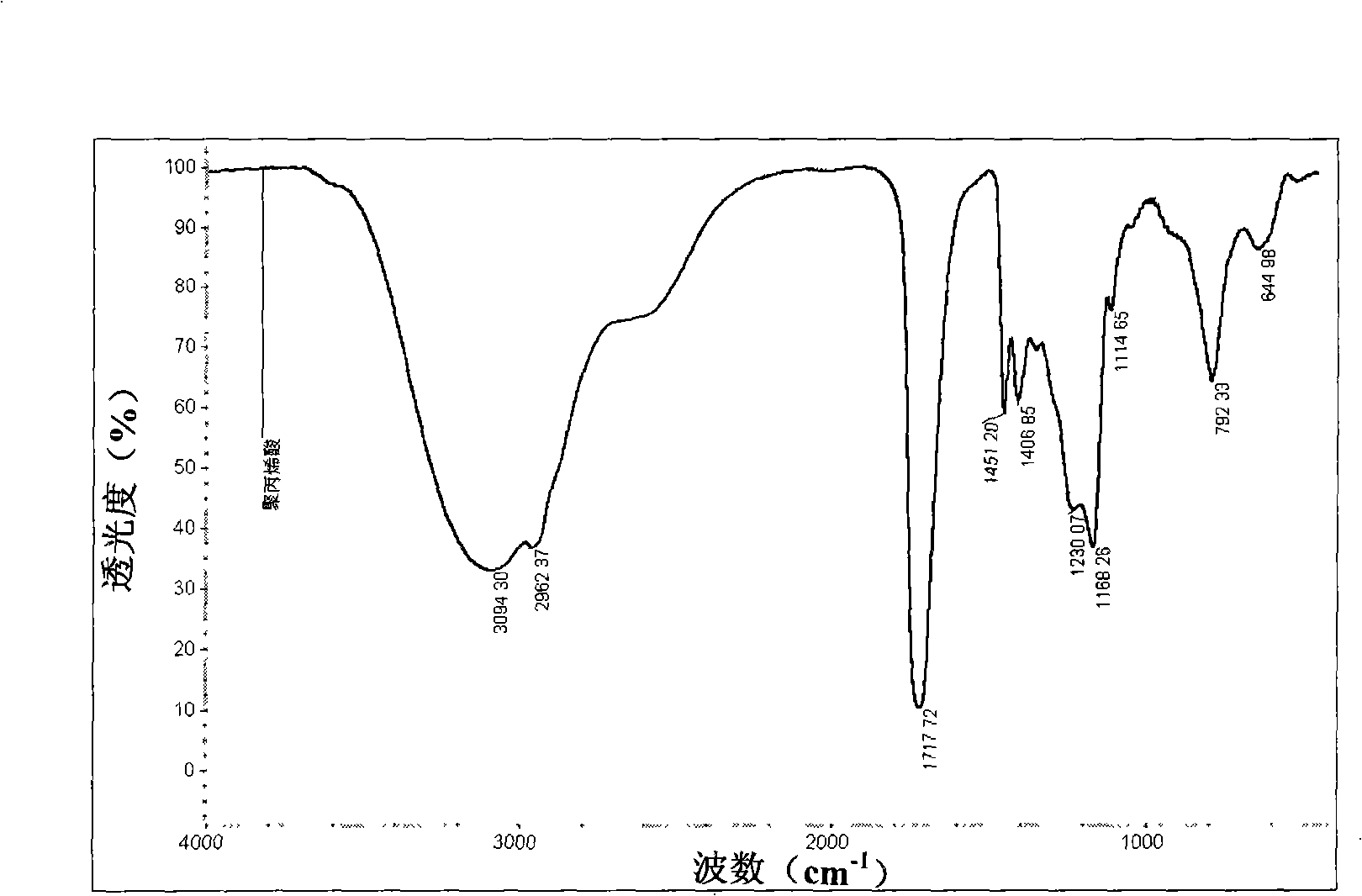

[0057] Add 1 part by weight of ammonium persulfate into the reactor, mix uniformly and start the temperature rise reaction, and control the reaction temperature between 50°C and 90°C. The reaction was stopped when the reaction mixture changed from a white turbid gel to a transparent gel. The gel is taken out and dried in an oven to obtain polyacrylic acid and acrylamide-based superabsorbent resin. Infrared spectra of polyacrylic acid and acrylamide superabsorbent resin figure 1 shown.

...

Embodiment 2

[0063] Add 85 parts by weight of acrylic acid, 10 parts by weight of methyl methacrylate, and 5 parts by weight of N,N-methylene bisacrylamide into the reactor, start electromagnetic stirring; add NaOH aqueous solution dropwise for neutralization, neutralization The degree is 75%. Wherein, the concentration of NaOH aqueous solution is 20wt%.

[0064] Add 1 part by weight of ammonium persulfate into the reactor, mix uniformly and start the temperature rise reaction, and control the reaction temperature between 50°C and 90°C. The reaction was stopped when the reaction mixture changed from a white turbid gel to a transparent gel. The gel was taken out and placed in an oven to dry.

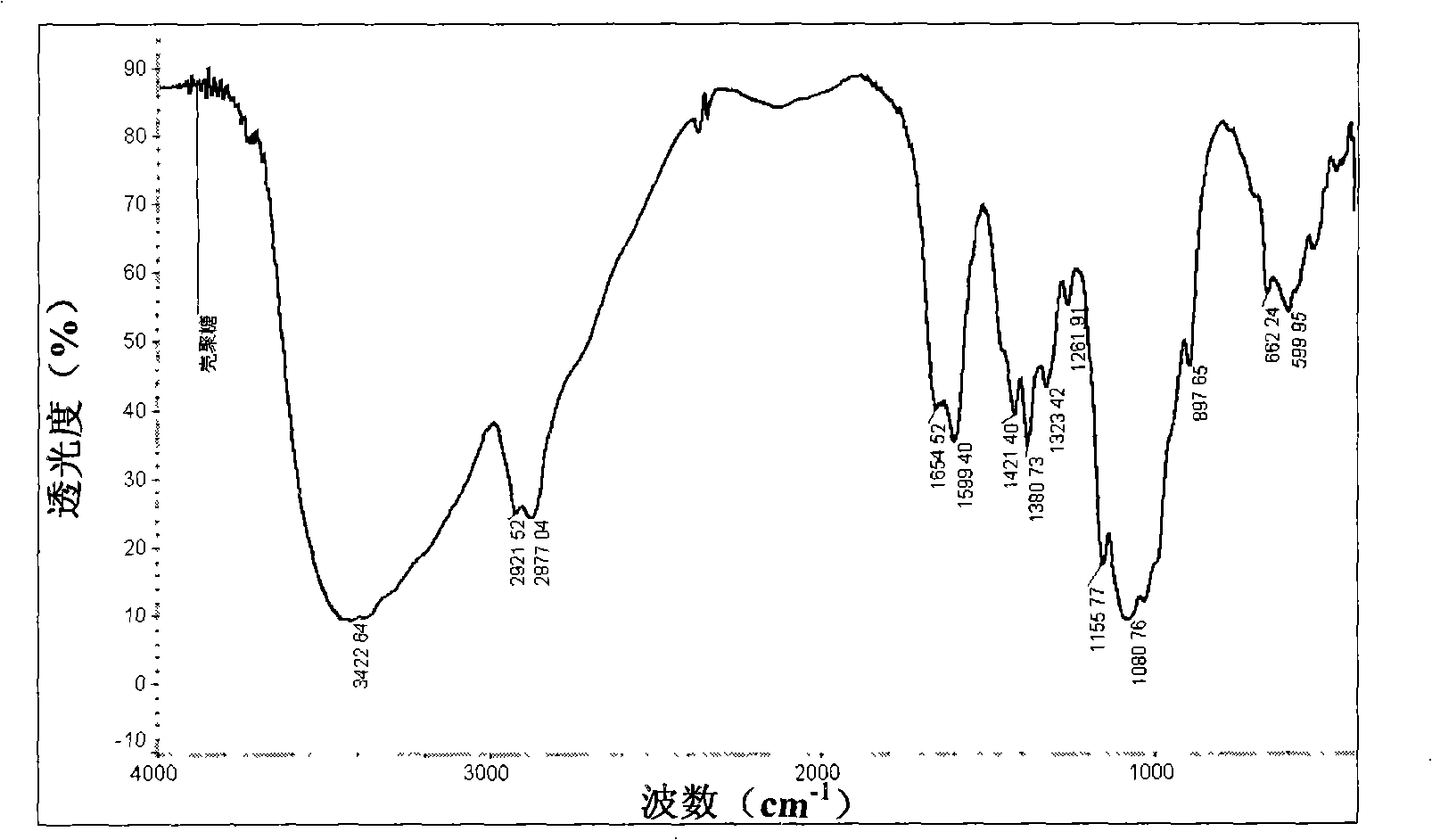

[0065] A chitosan aqueous solution with a concentration of 5 wt % is prepared, and 1 wt % cerium ammonium nitrate relative to the chitosan aqueous solution is added at the same time. The weighed dry polyacrylic acid-based superabsorbent resin was immersed in an aqueous chitosan solution with a conc...

Embodiment 3

[0070] Add 85 parts by weight of acrylic acid, 10 parts by weight of hydroxyethyl acrylate, and 5 parts by weight of ethylene glycol diacrylate into the reactor, start electromagnetic stirring; dropwise add NaOH aqueous solution for neutralization, and the degree of neutralization is 75%. Wherein, the concentration of NaOH aqueous solution is 20wt%.

[0071] Add 1 part by weight of ammonium persulfate into the reactor, mix uniformly and start the temperature rise reaction, and control the reaction temperature between 50°C and 90°C. The reaction was stopped when the reaction mixture changed from a white turbid gel to a transparent gel. The gel was taken out and placed in an oven to dry.

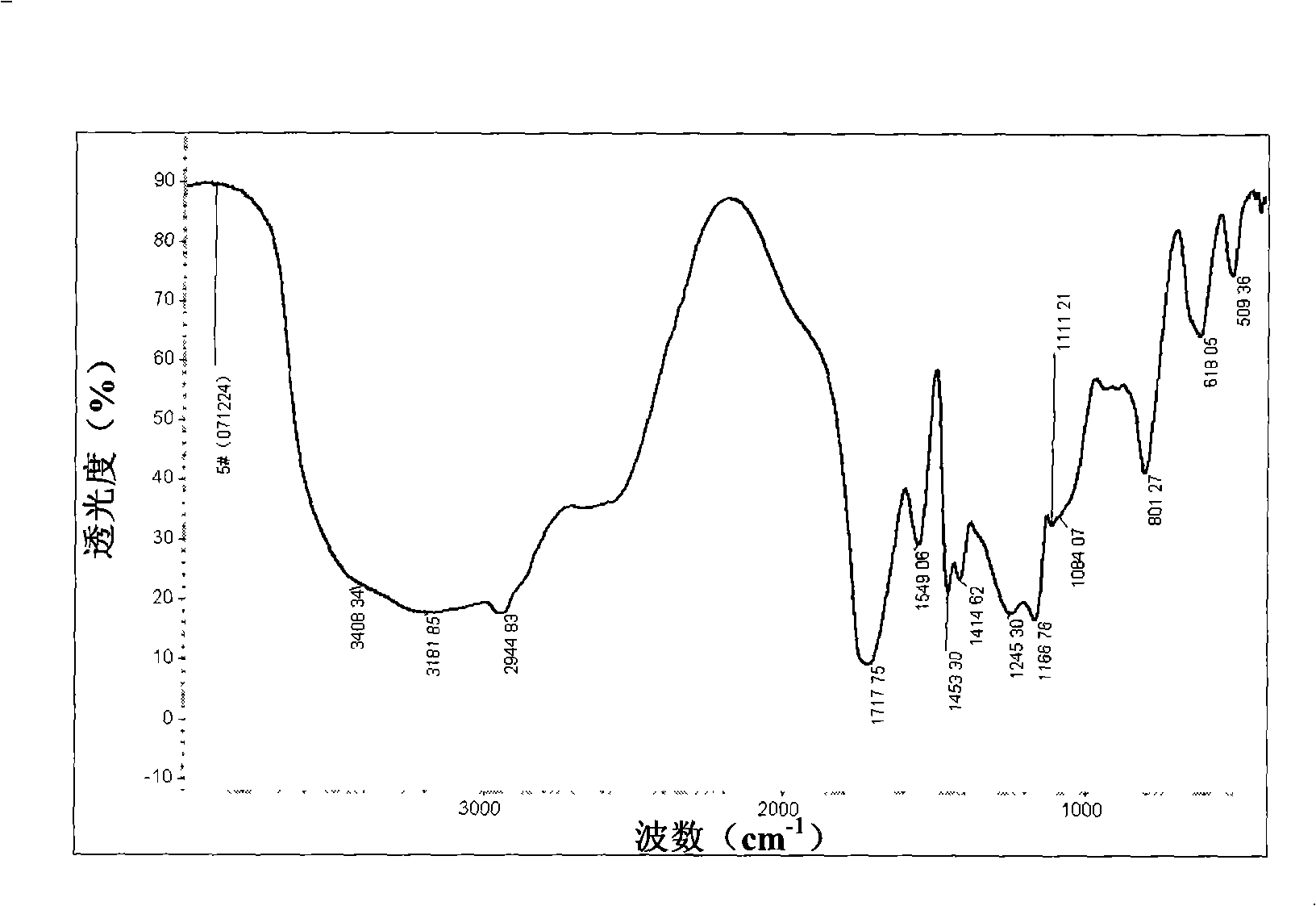

[0072] A chitosan aqueous solution with a concentration of 5 wt % is prepared, and 1 wt % cerium ammonium nitrate relative to the chitosan aqueous solution is added at the same time. The weighed dry polyacrylic acid-based superabsorbent resin was immersed in an aqueous chitosan solution with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com