Process for preparing L- molecular sieve membranes on different carriers

A technology of molecular sieves and carriers, which is applied in the field of preparing L molecular sieve membranes by uniformly coating seed crystals on carriers by baking, which can solve cumbersome operations, is not suitable for large-scale industrial applications, and cannot effectively obtain flat seed crystals Layer and other issues, to achieve the effect of good repeatability, easy operation, and short synthesis cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

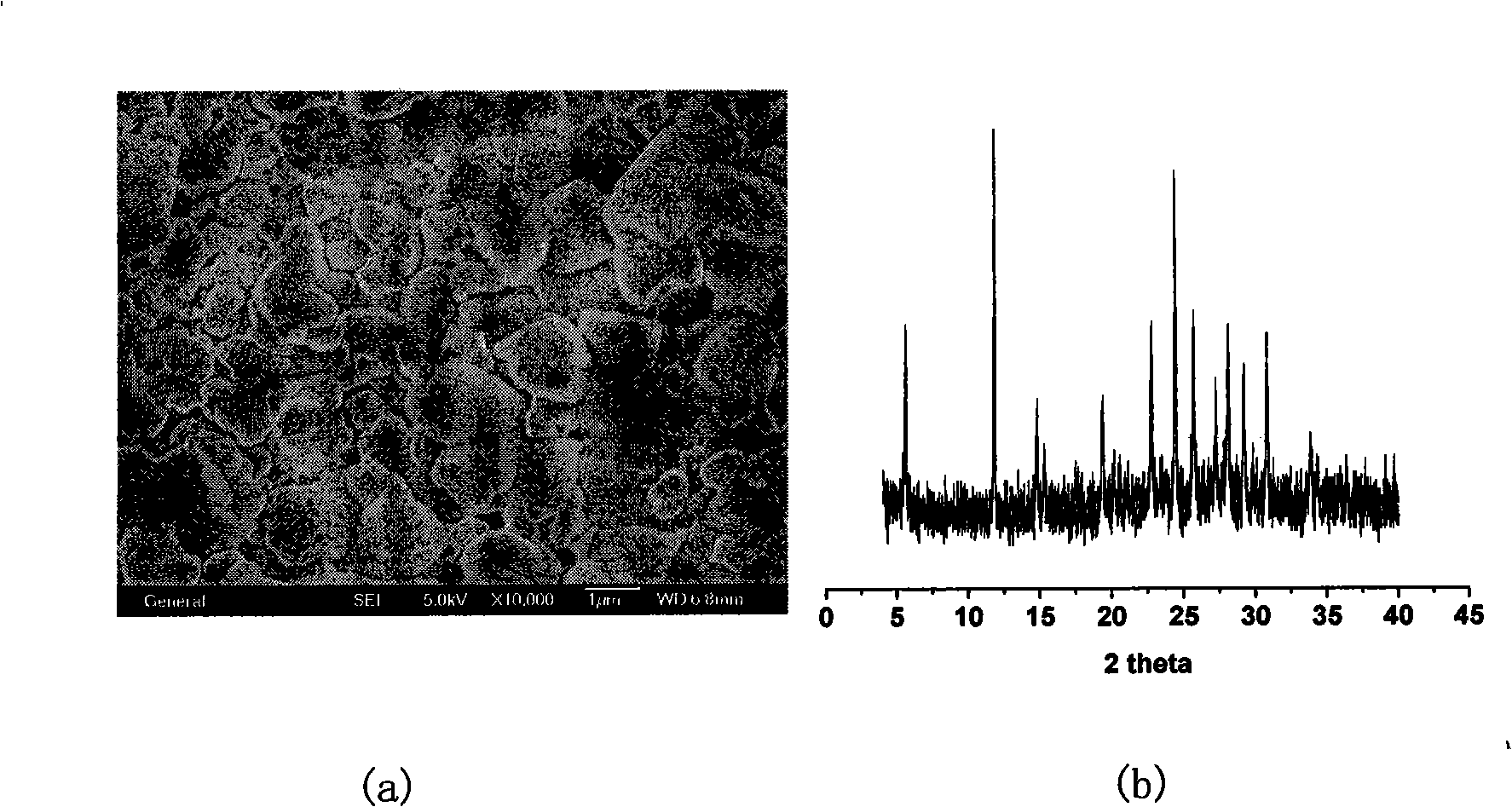

[0028] Embodiment 1: the preparation of the L molecular sieve membrane with stainless steel metal mesh as carrier

[0029] 1. Preparation of molecular sieve seed crystals: 8.4g KOH was dissolved in 10g distilled water, after the dissolution was complete, 30.0g silica sol (SiO 2 mass content is 30%), and the resulting stirring is solution I; 3.0g KOH is dissolved in 9.5g distilled water, and then 1.17g Al(OH) is added thereto 3 , heated and stirred until Al(OH) 3 Dissolve completely and compensate for lost moisture after cooling. Add the obtained solution drop by drop to solution I under stirring condition, stir evenly and put it into a reaction kettle, crystallize at 170°C for 7 days, then centrifuge and rinse with distilled water, put it into a beaker directly without drying , which is the seed crystal emulsion;

[0030] 2. The treatment of the carrier and the introduction of the crystal seed: put the stainless steel metal mesh (stainless steel metal mesh, China Xinxiang N...

Embodiment 2

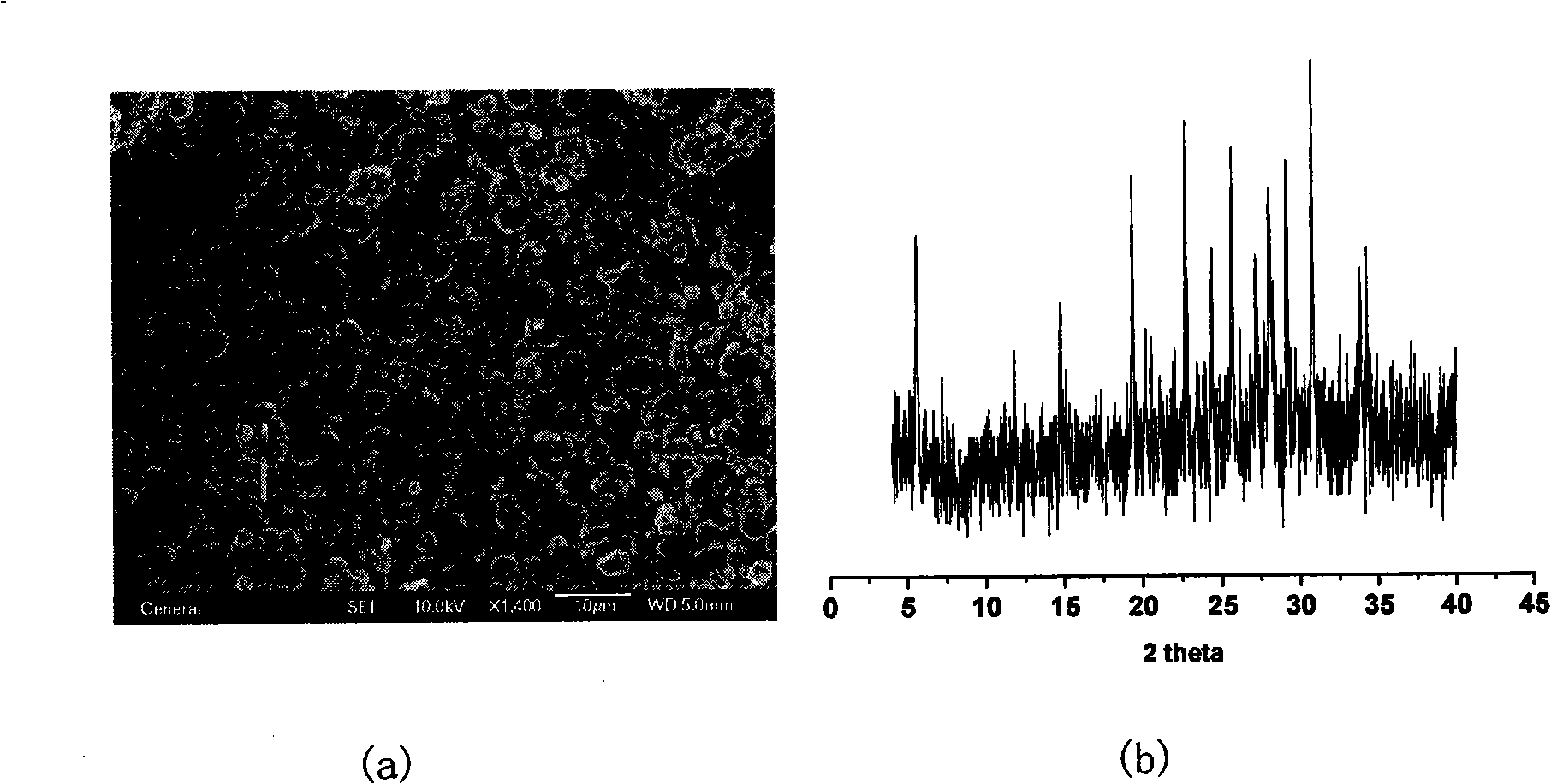

[0032] Embodiment 2: Preparation of L molecular sieve membrane with stainless steel mesh as carrier

[0033]The silicon source in the molecular sieve membrane synthesis solution was changed to white carbon black, the amount of which was 6.0 g, and the amount of water was 22.5 g, and the others were the same as in Example 1. The obtained film has good symbiosis, but the flatness is slightly reduced, and a small amount of miscellaneous crystals are formed. Its scanning electron microscope picture and X-ray diffraction picture are shown in figure 2 .

Embodiment 3

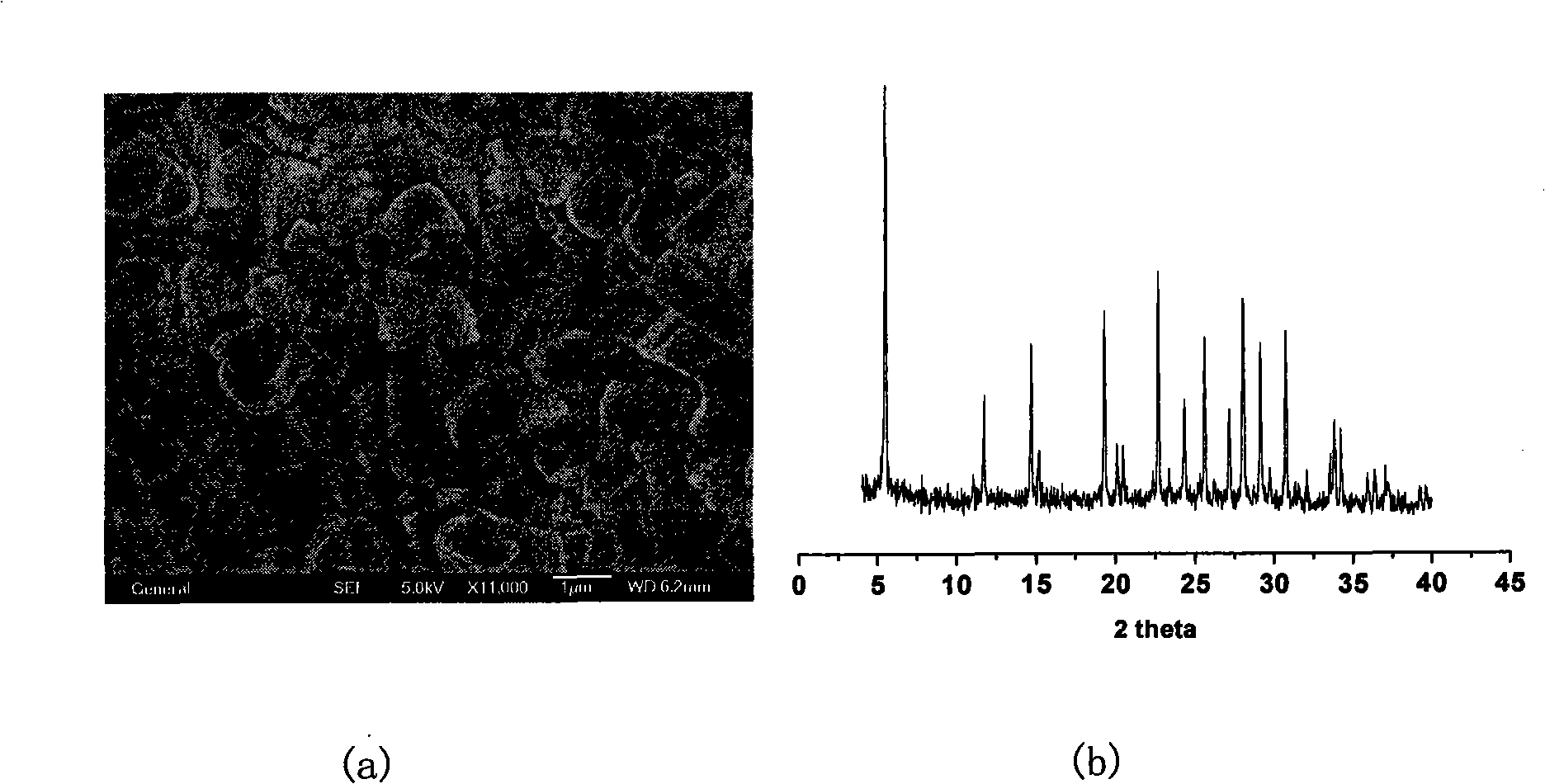

[0034] Embodiment 3: the preparation of the L molecular sieve membrane with ceramic sheet as carrier

[0035] Except that the carrier used is changed into a ceramic sheet, the others are the same as in Example 1. The resulting film is dense, without formation of miscellaneous crystals, and has a high degree of crystallinity. Its scanning electron microscope picture and X-ray diffraction picture are shown in image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com