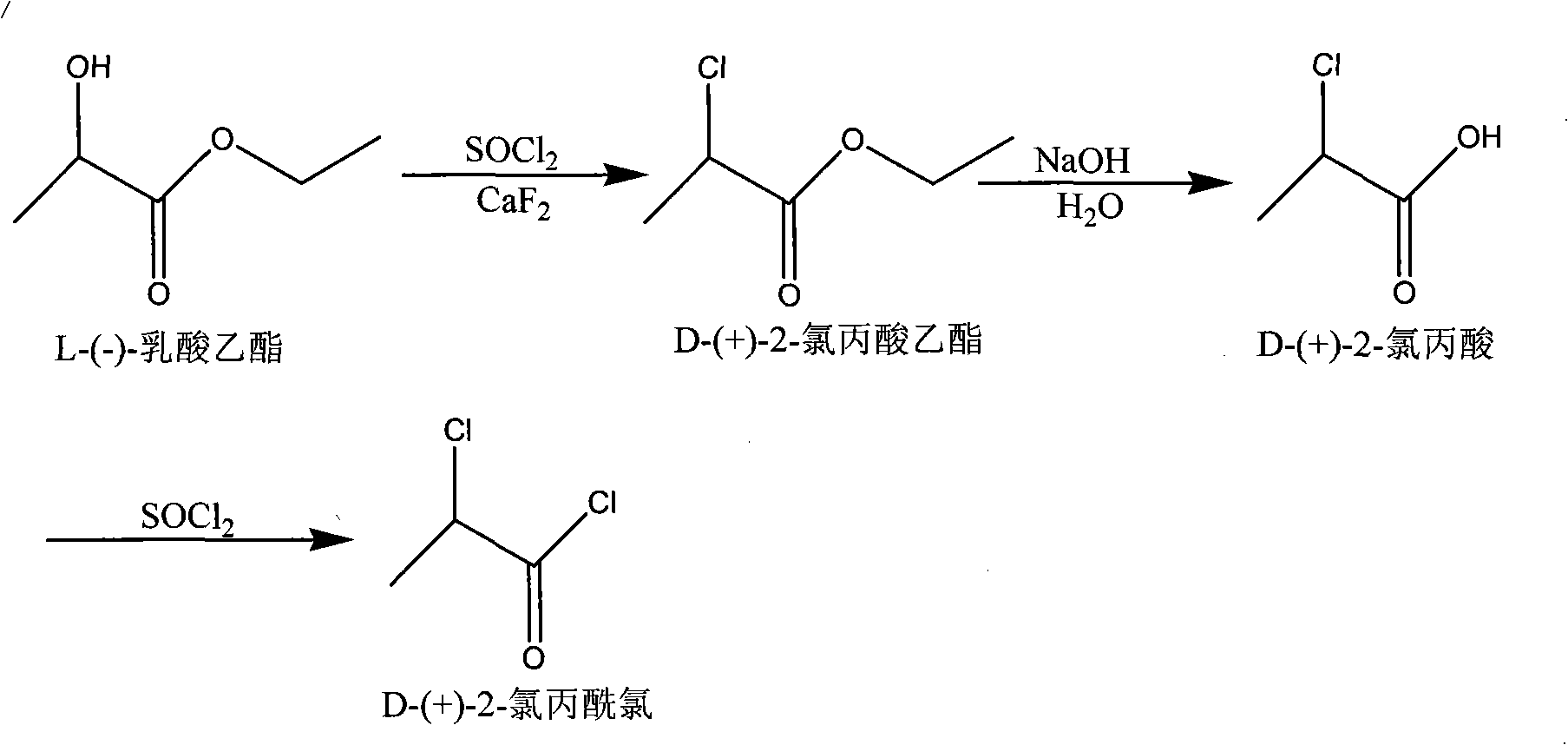

Synthetic method of D-(+)-2-chloro-propanoyl chloride

The technology of a chloropropionyl chloride and a synthesis method, which is applied in the synthesis field of D--2-chloropropionyl chloride, can solve problems such as low product yield, and achieve high product yield, novel reaction catalyst and no environmental impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Step a, synthetic D-(+)-2-chloropropionic acid ethyl ester

[0019] A four-necked reaction flask equipped with mechanical stirring and a hydrogen chloride absorber was installed, 125 grams of thionyl chloride and 10 grams of calcium fluoride catalyst were added, and 100 grams of L-ethyl lactate was added dropwise at room temperature (actually 27° C.). After dripping, heat up to 65-70°C, stir at constant temperature for 2 hours, heat up to 168°C for reflux reaction for 15 hours, stop the reaction, cool the reaction solution to room temperature (actually 27°C), enter the rectification tank for rectification to obtain D -(+)-2-Ethyl chloropropionate, the yield is 89.6%, the purity of the product reaches 99.5%, the optical purity of the chiral GC analysis reaches 97.1%, and the optical rotation of the product is +19.2 degrees.

[0020] Step b, synthesis of D-(+)-2-chloropropionic acid

[0021] Set a four-necked reaction flask equipped with mechanical stirring, add 70 grams...

Embodiment 2

[0025] Step a, synthetic D-(+)-2-chloropropionic acid ethyl ester

[0026] Set up a reaction kettle equipped with mechanical stirring and a hydrogen chloride absorber, add 240 kg of thionyl chloride and 10 kg of calcium fluoride catalyst, start stirring, and at room temperature (actually 25°C), feed at a rate of 5 kg / min , add 200 kg of L-ethyl lactate, after adding L-ethyl lactate, heat up to 65-70°C and stir for 3 hours, then heat up to 170°C for reflux reaction for 15 hours, stop the reaction, cool to room temperature (actually 25 ℃), enter the rectifying kettle and carry out rectification to obtain the D-(+)-2-chloropropionic acid ethyl ester product, the productive rate is 79.7%, the purity of the product reaches 99.5%, and the chiral GC analysis optical purity reaches 97.1%, The optical rotation of the product is +19.2 degrees.

[0027] Step b, synthesis of D-(+)-2-chloropropionic acid

[0028] Set up the reactor that mechanical stirring is housed, add 140 kilograms of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Optical rotation | aaaaa | aaaaa |

| Optical rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com