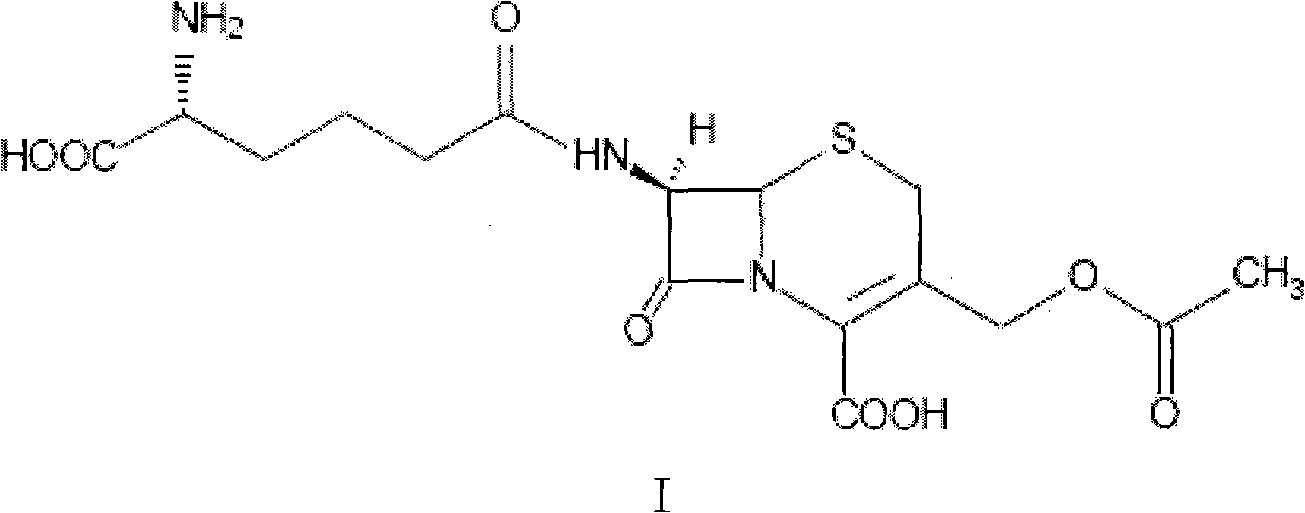

Macroporous adsorption resin special for extracting cephalosporin C and its preparation method

A technology of cephalosporin and adsorption resin, which is applied in the field of macroporous adsorption resin for cephalosporin C extraction and its preparation, which can solve the problems of adsorption resin performance, demanding price, high surface area and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

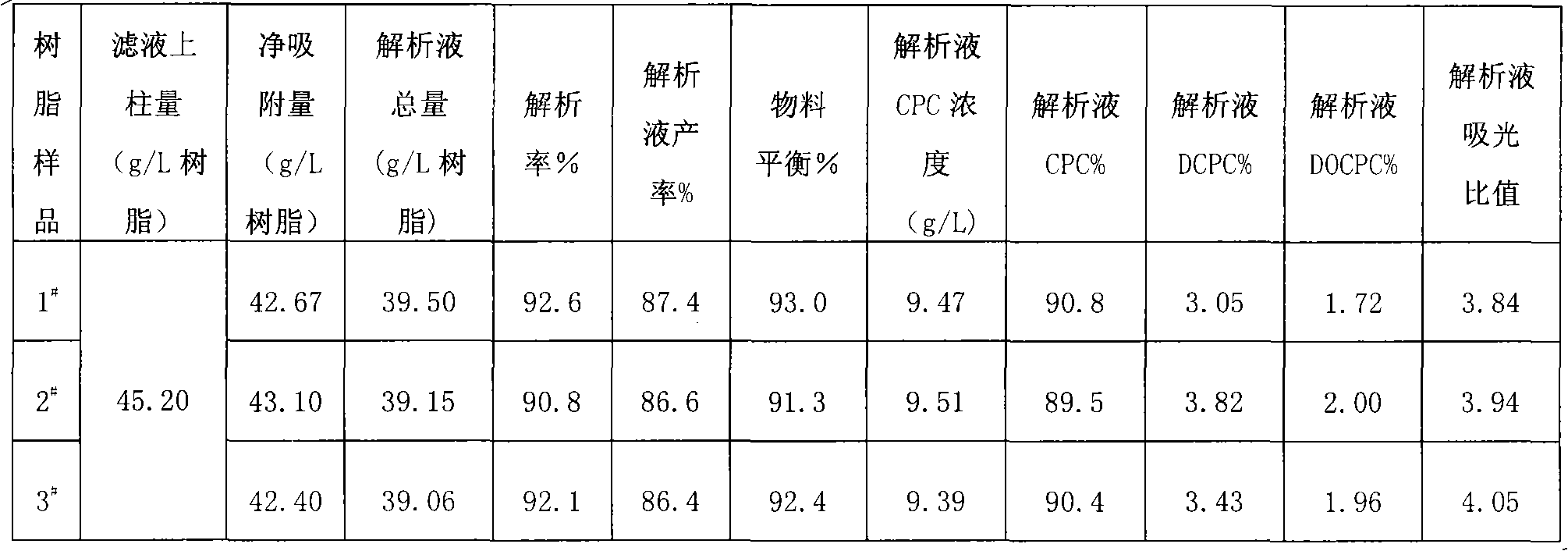

Examples

Embodiment 1

[0041] Example 1: Preparation of special macroporous adsorption resin for cephalosporin C extraction

[0042] A monomer mixture containing 75g (80% content) of divinylbenzene, 8g methyl methacrylate, 17g styrene, 90g toluene and 50g tert-amyl alcohol and 1.0g benzoyl peroxide was added to 500ml anhydrous salt, In the dispersion medium solution composed of 3.5g gelatin, stir to form uniform droplets of a certain size, raise the temperature to 70-75°C, react for 4 hours, then raise the temperature to 85°C, and react for 4 hours. Then the water is drained, hot water is added again, the temperature is raised, and the porogen (toluene and tert-amyl alcohol) is removed by azeotropic distillation until the condensate hardly contains oil, and the distillation is stopped. Lower the temperature, wash the spheres with a large amount of water, drain the water, then dry with hot air until the water content is below 1.0%, and sieve the spheres with 20-60 mesh to obtain 90 g of cross-linked ...

Embodiment 2

[0045] A monomer mixture containing 85g (80% content) of divinylbenzene, 5g methyl acrylate, 15g styrene, 100g toluene, 30g tert-amyl alcohol, 30g isooctane and 1.0g benzoyl peroxide was added to 500ml In the dispersion medium solution composed of no salt water and 3.5 g of gelatin, the remaining operations refer to Example 1 to obtain 95 g of cross-linked macroporous copolymer matrix.

[0046] Add 95g of the cross-linked macroporous copolymer matrix obtained above into 570ml of dichloroethane, stir and swell at room temperature for 2 hours, then add 19g of zinc chloride, raise the temperature to 80°C, and react for 15 hours. With reference to Example 1 for all the other operations, about 300g of brownish-yellow target product cephalosporin C is extracted with special macroporous adsorption resin, and its specific surface area is 1205m 2 / g, the pore volume is 1.84ml / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com