0-100Pa monolithic silicon based SOI high-temperature low drift micropressure sensor and processing method thereof

A micro-pressure sensor and low-drift technology, applied in the field of force-sensitive sensors, can solve problems such as inability to form large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

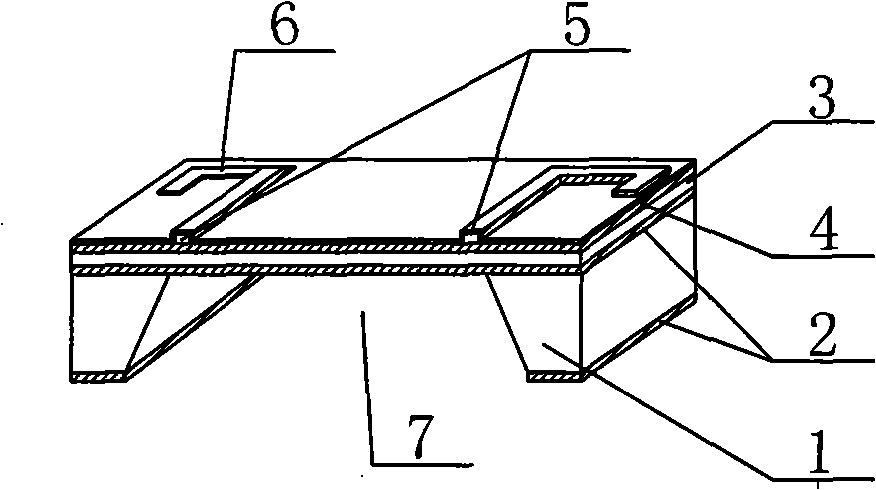

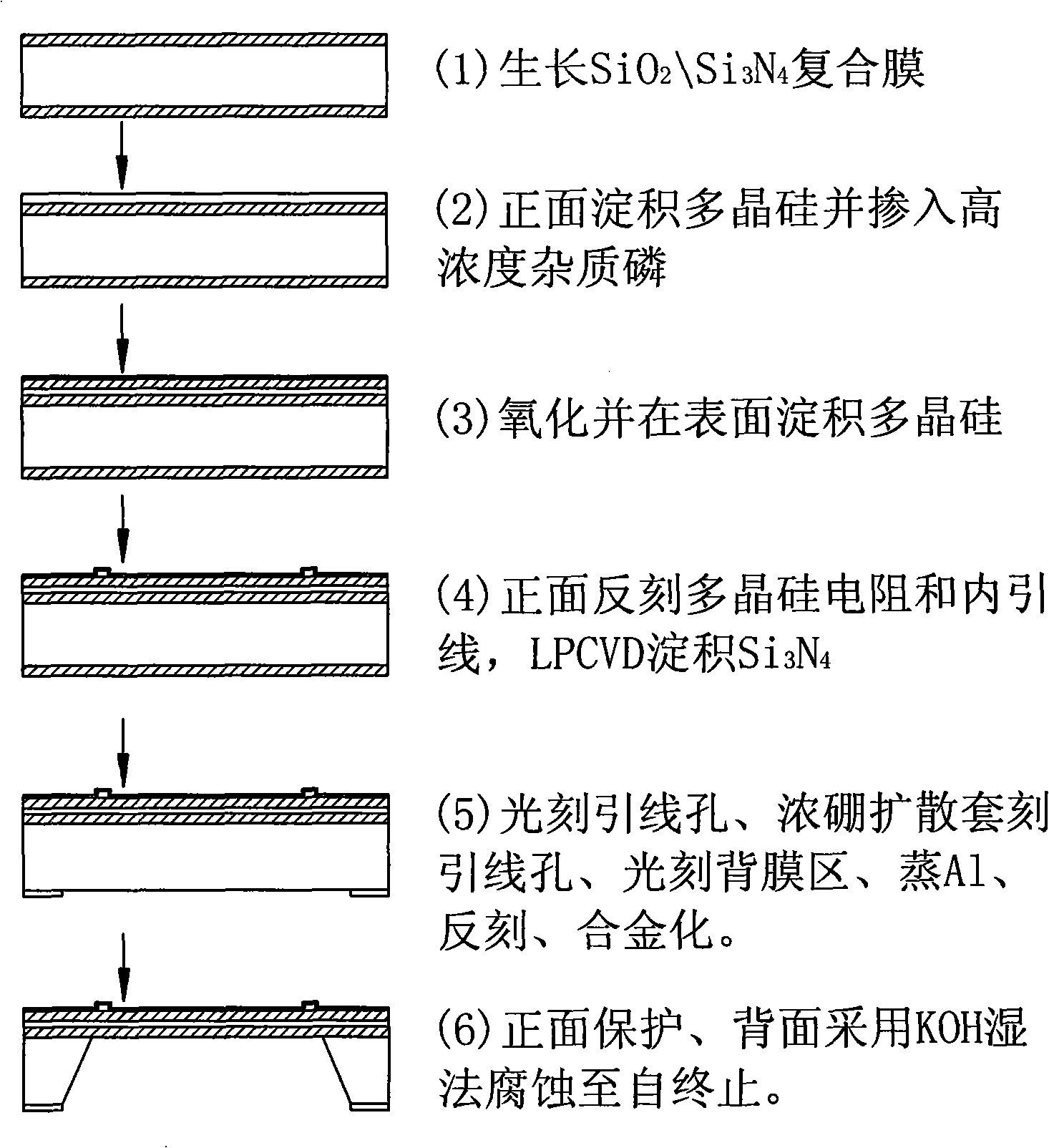

[0013] See figure 2 , the chip of the present invention includes an N-type or P-type silicon substrate 1, and an insulating layer 2 is covered on both sides of the silicon substrate, and the front insulating layer is a composite film composed of silicon dioxide and silicon nitride; the surface of the insulating layer 2 is deposited A polysilicon layer 3 of about 2 microns is deposited; a silicon dioxide layer 4 of 200 nanometers is grown on the surface of the polysilicon layer; a 600-nm polysilicon film layer is deposited on the surface of the silicon dioxide layer 4; the polysilicon film layer has four SOI polysilicon force-sensitive Resistor 5 and force-sensitive resistor 5 are made of polysilicon film; polysilicon inner lead 6 doped with concentrated boron is connected to resistor 5; force-sensitive resistor 5 and polysilicon inner lead 6 are attached to silicon dioxide / silicon nitride / polysilicon / dioxide The surface of the silicon multi-layer composite elastic film, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com