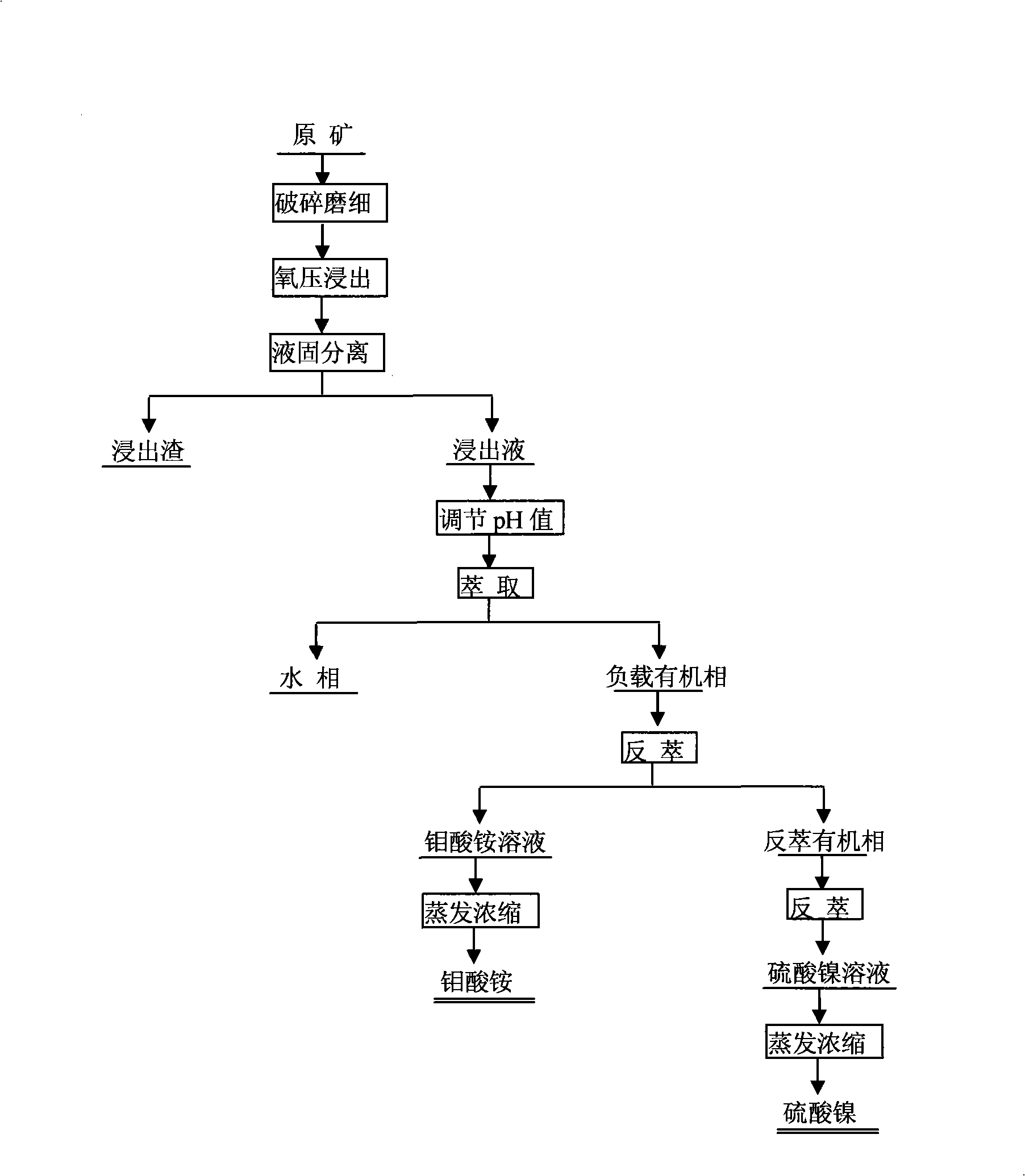

Process for separating molybdenum and nickel form black shale containing molybdenum and nickel

A black shale, molybdenum-nickel technology, applied in the field of metallurgy and chemical industry, can solve the problems of a large amount of flue gas, low leaching conversion rate, environmental pollution, etc., and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0024] 1. Raw materials: molybdenum content of 6.32%, nickel content of 3.05%, iron content of 15.27%, sulfur content of 21.58%, broken and pulverized -200 mesh (≥90%).

[0025] 2. Add industrial sulfuric acid with a concentration of 90% to 93% to adjust the slurry, control the concentration of sulfuric acid to 200g / L, and the solid-liquid mass volume ratio is 1:4. 150°C, under the condition of 1.5MPa internal pressure, the leaching reaction was carried out for 240 minutes, and the leaching residue and leaching solution were obtained by filtration, wherein the leaching solution was rich in molybdenum and nickel.

[0026] Molybdenum leaching rate: 90.37% Nickel leaching rate: 95.69%

[0027] 3. Add the solution rich in molybdenum and nickel into the storage tank, adjust the pH of the solution to 2.06, use the common extraction agent P204+TBP, control the extraction temperature at 25°C, and extract for 20 minutes under the condition of extraction ratio 1:2, Direct extraction of m...

example 2

[0034] 1. Raw materials: molybdenum content of 5.92%, nickel content of 3.17%, iron content of 16.69%, sulfur content of 17.88%, crushed and pulverized -200 mesh (≥90%).

[0035] 2. Add industrial sulfuric acid with a concentration of 90-93% to adjust the slurry, control the concentration of sulfuric acid to 100g / L, and the solid-liquid mass volume ratio is 1:6. At 200°C, under the condition of 3.0MPa internal pressure, the leaching reaction was carried out for 60 minutes, and the leaching residue and leaching solution were obtained by filtration, wherein the leaching solution was rich in molybdenum and nickel.

[0036] Molybdenum leaching rate: 82.16% Nickel leaching rate: 91.73%

[0037] 3. Add the solution rich in molybdenum and nickel into the storage tank, adjust the pH of the solution to 2.13, use the common extraction agent P204+TBP, control the extraction temperature at 15°C, and extract for 10 minutes under the condition of extraction ratio 1:1. Direct extraction of ...

example 3

[0044] 1. Raw materials: molybdenum content of 4.58%, nickel content of 2.79%, iron content of 7.37%, sulfur content of 23.16%, crushed and pulverized - 200 mesh (≥90%).

[0045] 2. Add industrial sulfuric acid with a concentration of 90-93% to adjust the slurry, control the concentration of sulfuric acid to 250g / L, and the solid-liquid mass volume ratio is 1:2. The temperature is 100°C and the pressure in the kettle is 1.0MPa, the leaching reaction is carried out for 150 minutes, and the leaching residue and leaching solution are obtained by filtration, wherein the leaching solution is enriched in molybdenum and nickel.

[0046] Molybdenum leaching rate: 86.28% Nickel leaching rate: 95.33%

[0047] 3. Add the solution rich in molybdenum and nickel into the storage tank, adjust the pH of the solution to 1.92, use the common extraction agent P204+TBP, control the extraction temperature at 35°C, and extract for 30 minutes under the condition of extraction ratio 1:3. Direct extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com