Lactoferrin antimicrobial peptide, preparing method and uses thereof

A lactoferrin and antimicrobial peptide technology, applied in the field of lactoferrin antimicrobial peptide and its preparation, can solve problems such as lack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

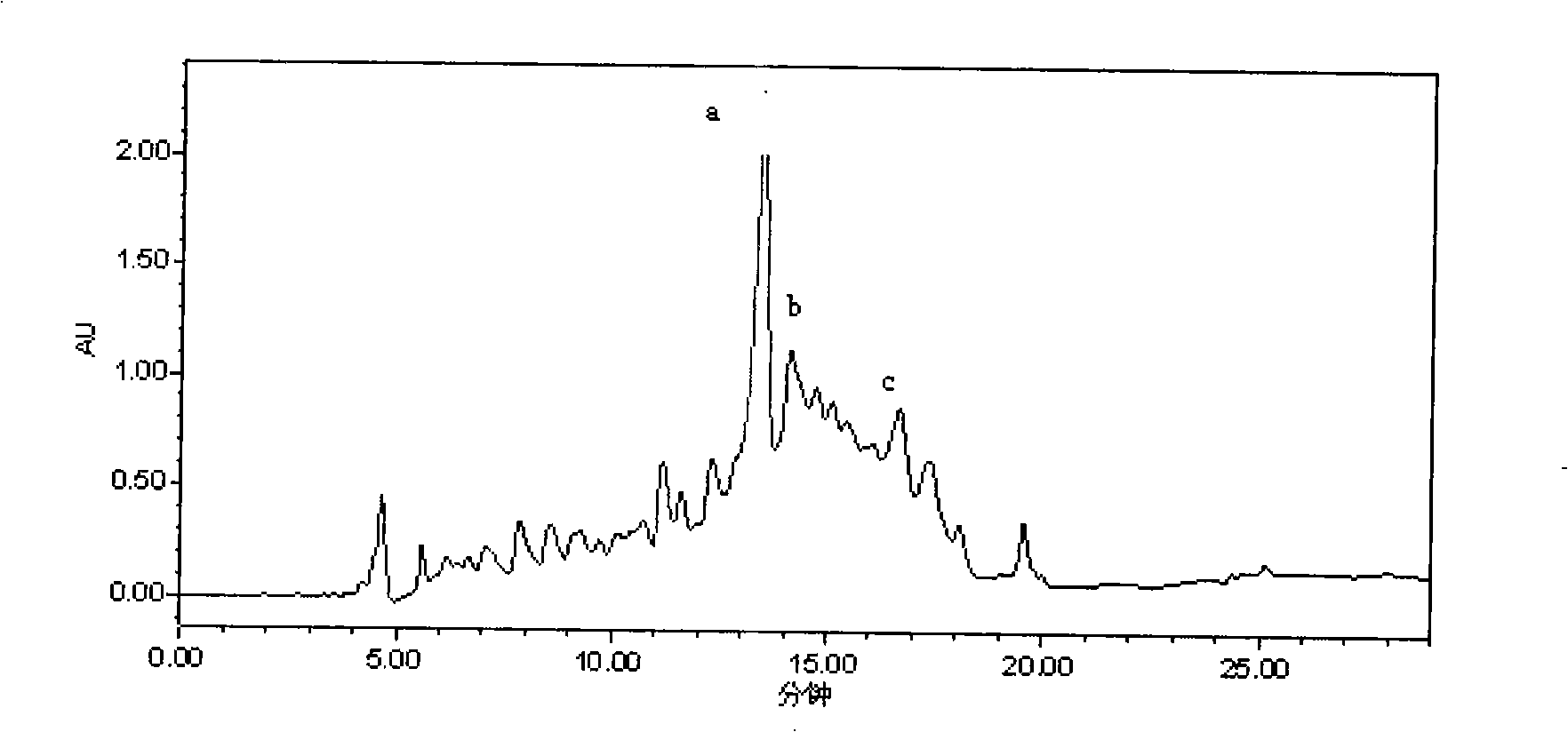

[0099] Weigh the lactoferrin sold by DMV Company under the trade name lactoferrin (Lactoferrin) with a purity greater than 90% and put it in an enzyme reactor, add deionized water and stir to obtain a concentration of 50mg / mL lactoferrin. Pretreatment at 40°C for 20 minutes, then adjust the pH of the solution to 2.5 with 1.0mol / L HCl, add 0.5% EC3.4.23.1 pepsin produced by Sigma in terms of lactoferrin weight, and then control the pH of the reaction system Constant, carry out enzymolysis at this temperature, use the TNBS method to measure the degree of hydrolysis until the degree of hydrolysis reaches 11%, after the reaction is completed, inactivate the enzyme at 100°C for 5 minutes, adjust the pH of the solution to 7.0, and proceed at 10000r / min Refrigerated and centrifuged for 20 min, the supernatant was concentrated. The bacteriostatic rate of the lactoferrin antimicrobial peptide hydrolyzate was 94.32% at 1 mg / mL.

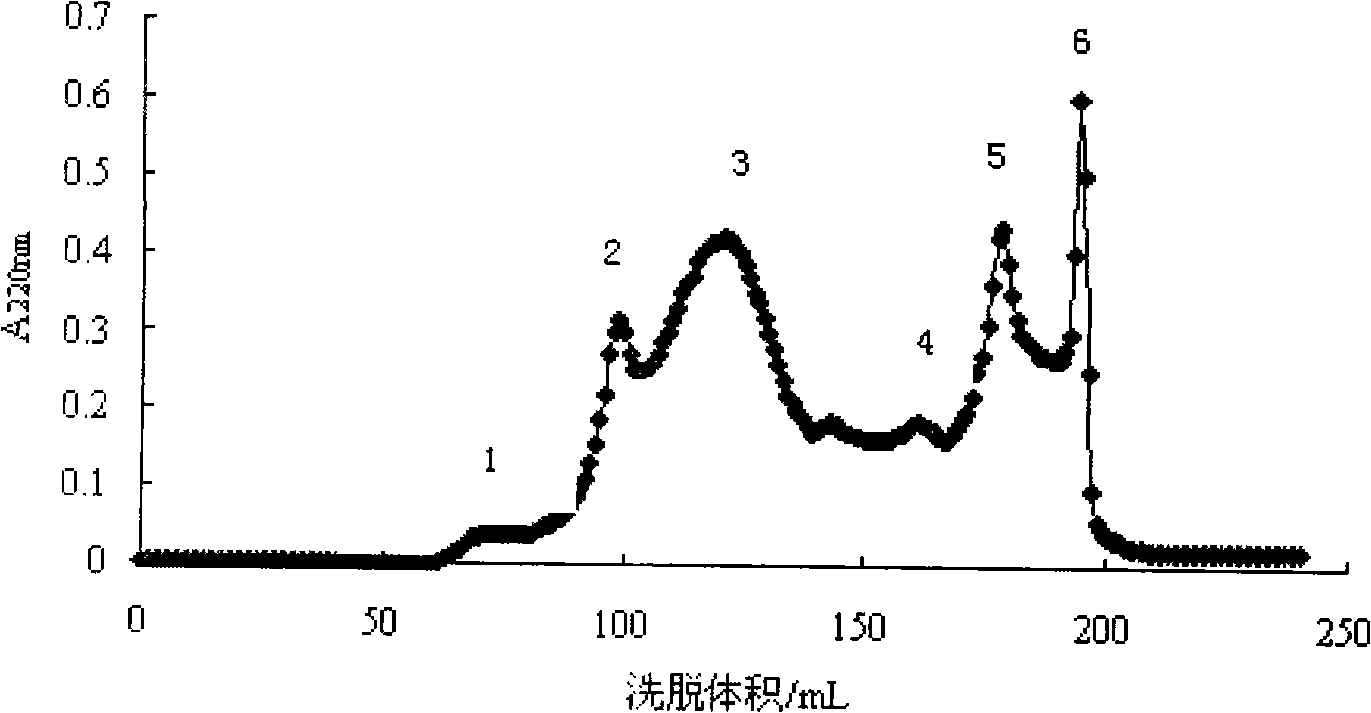

[0100] The macroporous adsorption resin sold under the t...

Embodiment 2

[0105] This embodiment is implemented in the same manner as in Example 1, but the lactoferrin sold by DMV Company under the trade name lactoferrin (Lactoferrin) with a purity greater than 90% is put into an enzyme reactor, and deionized water is added to stir Uniformly prepare lactoferrin with a concentration of 10mg / mL, pretreat at 50°C for 10min, adjust the pH to 7.0 with 1.0mol / L NaOH, add 4% Novozyme 6.0S trypsin by weight of lactoferrin, during the reaction Keep the pH constant. After the reaction, inactivate the enzyme at 90°C for 8 minutes, adjust the pH to 7.0, refrigerate and centrifuge at 7000r / min for 30 minutes, concentrate the supernatant, and freeze-dry. thing. When the lactoferrin antimicrobial peptide hydrolyzate was at 1 mg / mL, the bacteriostatic rate was 67.39%.

[0106]Use DA201-B macroporous resin for static desalting, add lactoferrin antibacterial peptide, shake at 20°C at 150r / min for 12 hours, discard the supernatant, add deionized water, and wash until...

Embodiment 3

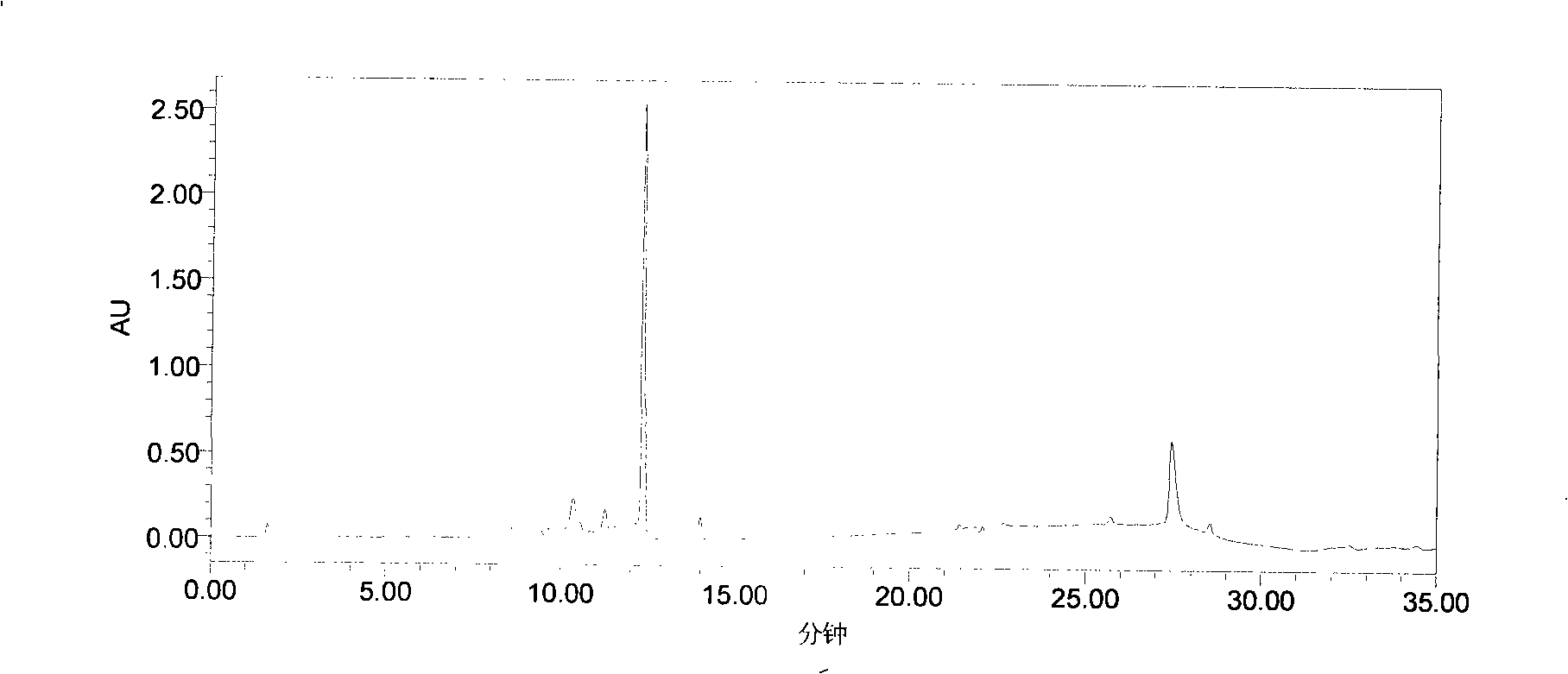

[0111] This embodiment is implemented in the same manner as in Example 1, but the lactoferrin sold by DMV Company under the trade name lactoferrin (Lactoferrin) with a purity greater than 90% is put into an enzyme reactor, and deionized water is added to stir Uniformly prepare lactoferrin with a concentration of 15mg / mL, pretreat at 50°C for 10 minutes, adjust the pH to 7.0 with 1.0mol / L NaOH, add 1.5% AS1398 neutral protease based on the weight of lactoferrin, and control the pH of the reaction system. After the reaction, inactivate the enzyme at 85°C for 10 minutes, adjust the pH to 7.0, and refrigerate and centrifuge at 9000 r / min for 20 minutes, and concentrate the obtained supernatant. Use DA201-D macroporous resin for static desalting, add lactoferrin antibacterial peptide at 160r / min, stir for 7 hours, discard the supernatant, add deionized water, wash until the conductivity is less than 15μs / cm, add 85 % ethanol for elution, the eluate was concentrated, and freeze-drie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com