Thickening/foam boosting agent

A technology of foam booster and cleaning agent, which is applied in the direction of detergent composition, detergent compounding agent, skin care preparation, etc., and can solve the problems of no odor, foaming property, record, and no raw material alcohol content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

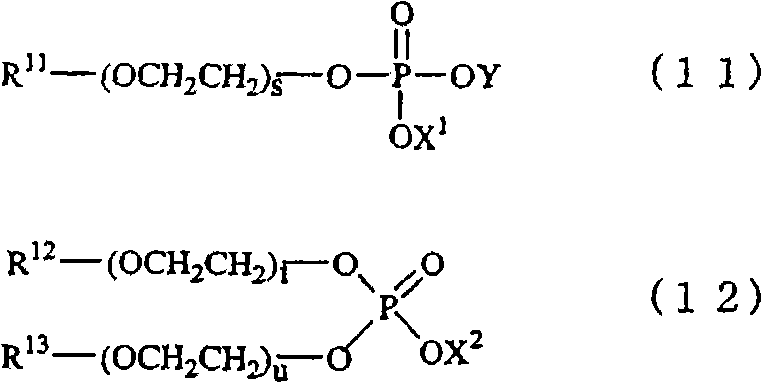

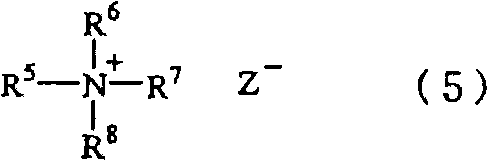

Method used

Image

Examples

manufacture example 1

[0090] Add 1615.0 g (12.35 moles) of 1-octanol (KALCOL 0898, manufactured by Kao Corporation) and 6.9 g (0.12 moles) of potassium hydroxide to the autoclave, dehydrate at 110 °C and 13.3 kPa, then at 120 °C, 1434 g (24.69 mol) of propylene oxide was injected at 0.3 MPa to carry out the addition reaction.

[0091] After the reaction was completed, aging was carried out at the same reaction temperature for 6 hours, and then cooled to 80°C.

[0092] As a post-treatment, 55 g of a synthetic adsorbent (KYOWORD600S, Kyowa Chemical Industry Co., Ltd.) was added to the obtained reaction composition, and the catalyst was removed by filtration after treatment at 4.0 kPa for 1 hour. The 1-octanol content of the obtained filtrate was quantitatively determined by gas chromatography to be 9000 ppm.

[0093] Next, 1-octanol was removed by distillation with respect to 1,000 g of the obtained filtrate under conditions of 130° C. and 1.3 kPa. Then, 100 g of steam was blown in under the condit...

manufacture example 2

[0096] In the same manner as in Production Example 1, alkylene glycol ethers 2 to 12 shown in Table 1 (product of the present invention) and Table 2 (comparative product) were obtained. The alkylene glycol ethers 2 to 5 were purified in the same manner as in Production Example 1, and the alkylene glycol ethers 6 to 12 were only subjected to the removal of the catalyst by filtration as shown in Production Example 1, and no purification by distillation was performed. The amount of raw material alcohol in the obtained alkylene glycol ether was quantitatively measured by gas chromatography.

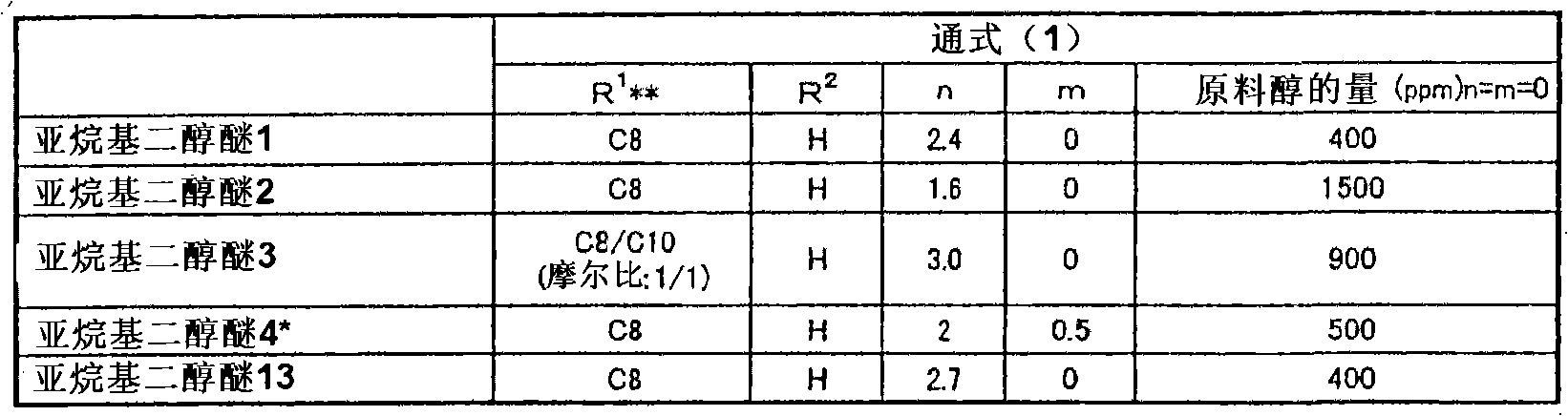

[0097] [Table 1]

[0098]

[0099] * (PO)n / (EO)m is arranged in blocks in the order of (PO)n, (EO)m relative to R1

[0100] ** C8: n-octyl, C10: n-decyl

[0101] [Table 2]

[0102]

[0103] * R-O-(C 2 h 4 O) p -[(C 2 h 4 O) q / (AO) r ]-H

[0104] [(C 2 h 4 O) q / (AO) r ] for random

[0105] R=isodecyl alcohol, p=4, q=1.5, AO=PO, r=1.5

[0106] ** C8: n-octyl, C12: n...

Embodiment 1

[0108] Using the alkylene glycol ethers 1 to 12 and surfactants shown in Tables 1 and 2, detergent compositions were prepared according to the usual method, and the viscosity, foaming property and odor were evaluated by the following methods.

[0109] The measurement conditions of the viscosity are as follows. The results are shown in Tables 3 and 4.

[0110] (1) Viscosity measurement

[0111] Viscometer used: B-type viscometer (manufactured by Tokyo Keiki Co., Ltd.)

[0112] Rotor No. / speed: No.1 / 12rpm, measurement time: 1 minute

[0113] Temperature 30°C: Place the glass bottle with the sample in a constant temperature bath at 30°C±1 for 1 hour and measure

[0114] (2) Foaming test and odor test

[0115] 1 ml of each cleansing composition described in Tables 3 and 4 was dropped on the palm, and 10 specialists evaluated the foaming property and odor after cleaning hands and arms according to the following evaluation criteria.

[0116] (foaming)

[0117] 4: The foamabili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com