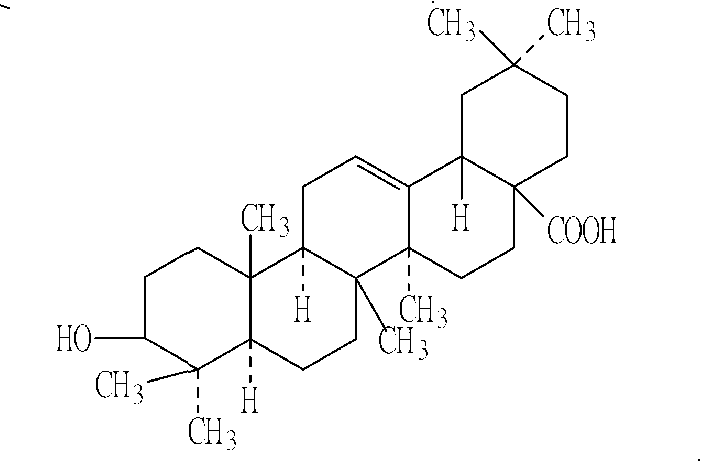

Oleanolic acid dispersible tablet and preparation method thereof

A technology of oleanolic acid and dispersible tablets, which is applied in the direction of medical preparations containing active ingredients, pharmaceutical formulas, organic active ingredients, etc., can solve the problems of low bioavailability of oleanolic acid, enrich the market, and improve dissolution The effect of the degree and the simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

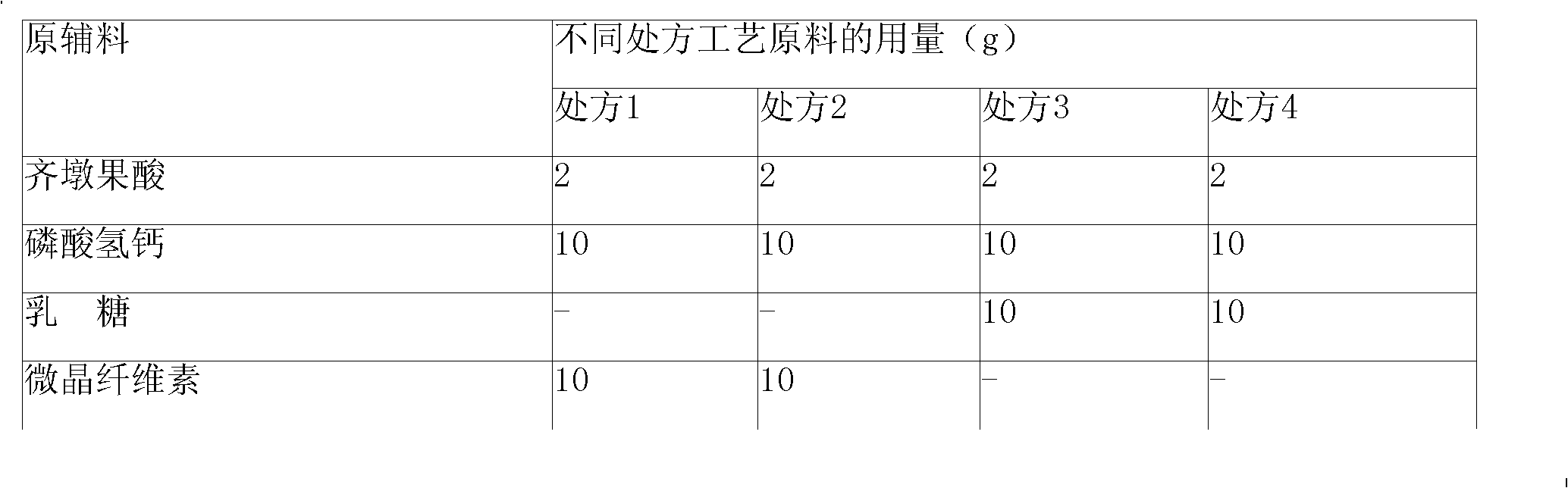

Embodiment 1

[0043] Embodiment 1: oleanolic acid 20g, calcium hydrogen phosphate 100g, lactose 100g, 10% povidone K 30 9g of ethanol solution, 24g of crospovidone, 2.5g of sodium lauryl sulfate, 0.5g of sucralose, 2g of magnesium stearate, 95% ethanol

[0044] Take oleanolic acid and micronize it so that the particle size is below 10 μm, add calcium hydrogen phosphate, lactose, 10 g of crospovidone, sodium lauryl sulfate, sucralose and magnesium stearate, and mix well , adding 10% povidone K 30 The ethanol solution was passed through a 20-mesh sieve, granulated, dried at 45° C., passed through a 24-mesh sieve for granulation, added the remaining 14 g of crospovidone, mixed evenly, compressed into tablets, and made into 1000 tablets.

[0045] Usage and dosage: take orally. 1-4 tablets each time, 3 times a day.

Embodiment 2

[0046] Embodiment 2: oleanolic acid 15g, calcium hydrogen phosphate 100g, lactose 90g, 10% povidone K 30 10g of ethanol solution, 26g of crospovidone, 2g of sodium lauryl sulfate, 0.6g of sucralose, 1.5g of magnesium stearate, 95% ethanol

[0047]Take oleanolic acid and micronize it so that the particle size is below 10 μm, add calcium hydrogen phosphate, lactose, 11 g of crospovidone, sodium lauryl sulfate, sucralose and magnesium stearate, and mix well , adding 10% povidone K 30 The ethanol solution was passed through a 20 mesh sieve, granulated, dried at 45°C, passed through a 24 mesh sieve for granulation, added the remaining 15g of crospovidone, mixed evenly, compressed into tablets, and made into 1000 pieces.

[0048] Usage and dosage: take orally. 1-4 tablets each time, 3 times a day.

Embodiment 3

[0049] Embodiment 3: oleanolic acid 25g, calcium hydrogen phosphate 90g, lactose 120g, 10% povidone K 30 8g of ethanol solution, 22g of crospovidone, 3g of sodium lauryl sulfate, 0.4g of sucralose, 2.5g of magnesium stearate, 95% ethanol

[0050] Take oleanolic acid and take oleanolic acid and carry out micronization treatment to make its particle size below 10 μm, add calcium hydrogen phosphate, lactose, 11g crospovidone, sodium lauryl sulfate, sucralose and hard Magnesium fatty acid, mix well, add 10% Povidone K 30 The ethanol solution was passed through a 20 mesh sieve, granulated, dried at 45°C, passed through a 24 mesh sieve for granulation, added the remaining 15g of crospovidone, mixed evenly, compressed into tablets, and made into 1000 pieces.

[0051] Usage and dosage: take orally. 1-4 tablets each time, 3 times a day.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com