Fermentative production of non-volatile microbial metabolism products in solid form

A non-volatile, metabolite technology, applied in the field of non-volatile microbial metabolites, which can solve complex problems, cannot be widely used, and is not optimized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

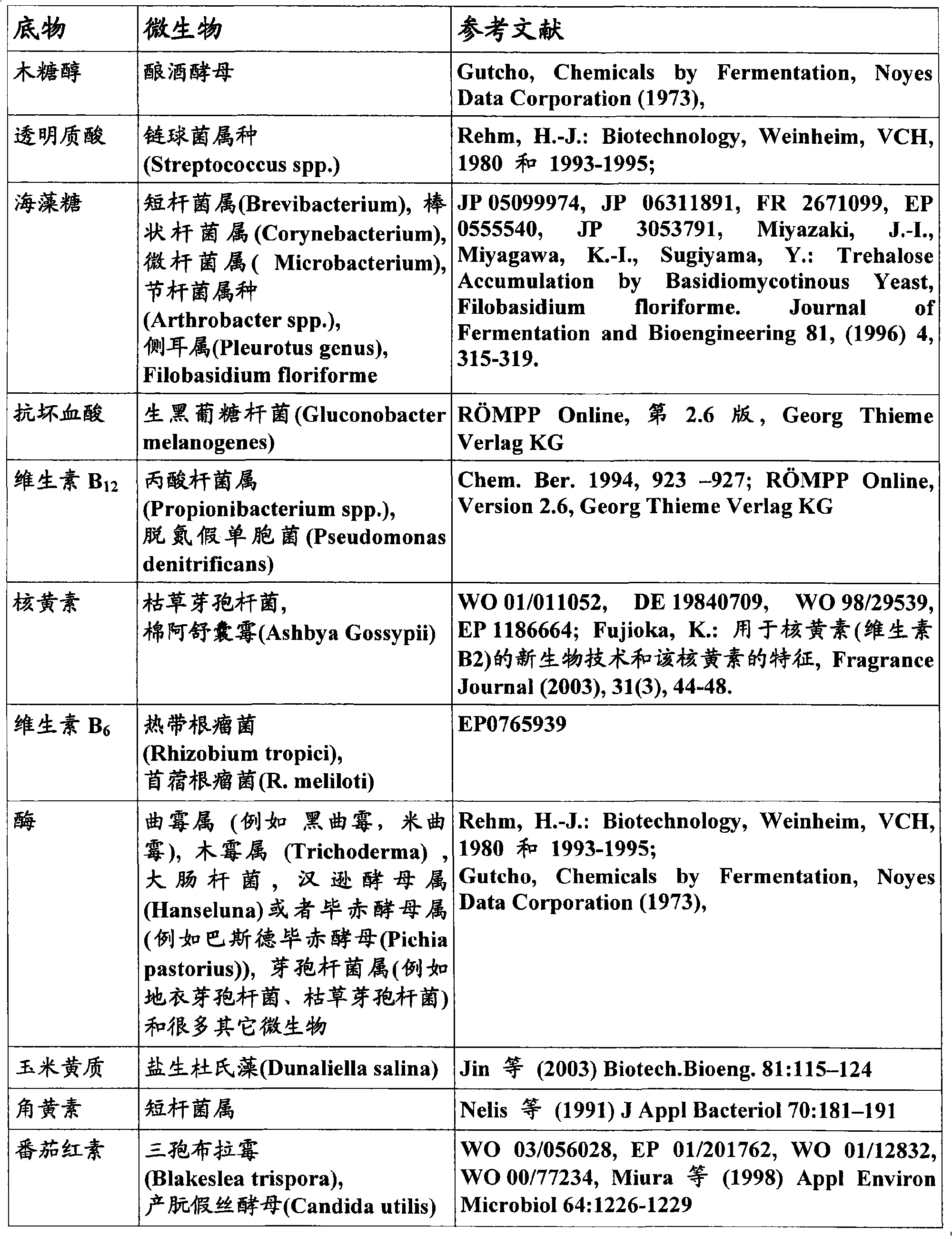

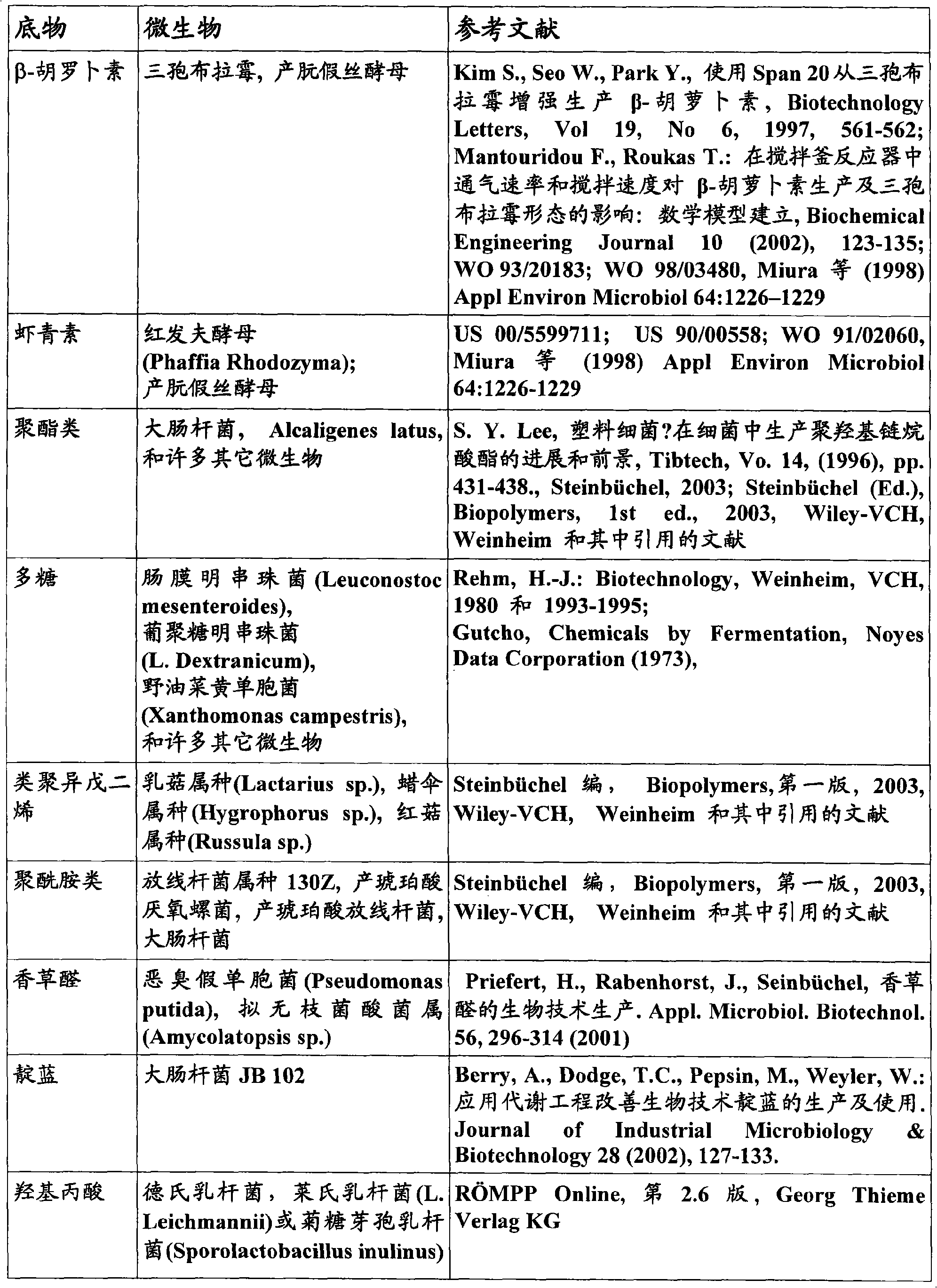

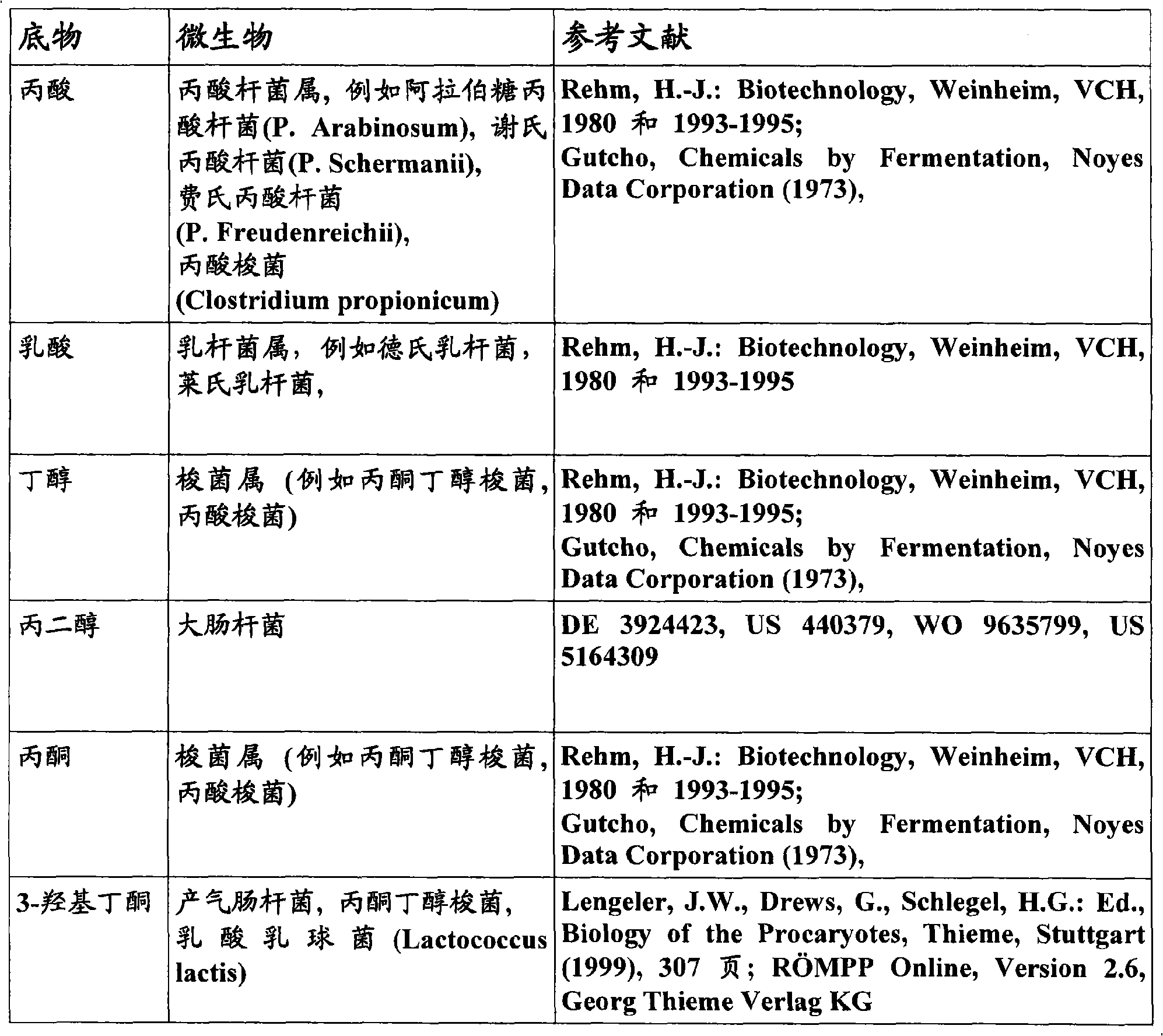

Method used

Image

Examples

Embodiment 1

[0236] a) Enzymatic starch liquefaction and saccharification

[0237] 500 grams of dry ground grits were suspended in 750 ml of water and finely ground again in a stirring mixer. The suspension was divided into four samples, Nos. 1 to 4, and each sample was treated with about 3 grams of thermostable alpha-amylase (Samples Nos. 1 and 2: Termamyl L; Samples Nos. 3 and 4: Spezyme). Samples No. 2 and No. 4 were then treated with approximately 7 g / l glucoamylase (Sample No. 2: Dextrozyme GA; Sample No. 4: Optidex). This gave pale yellow viscous samples, the solid contents of which were separated by centrifugation in each case, with a layer of hydrophobic solids floating above the clear liquid phase.

[0238] The clear supernatant of each sample obtained in this way was analyzed using HPLC in concentrated form and after 10-fold dilution, ignoring or taking into account the precipitate that had been centrifuged. When considering the precipitate, it is assumed that the dry matter co...

Embodiment 2

[0270] Using the corn meal hydrolyzate obtained according to Example II.1, with ATCC13032lysC described in WO 05 / 059144 fbr The strains were fermented analogously to example 1 b). Cells were incubated on sterile CM agar (composition see Table 4; 20 minutes at 121°C) for 48 hours at 30°C. Cells were then scraped from the plate and resuspended in saline. In each case, the optical density at 610 nm was achieved using the thus-prepared 610 A cell suspension with a value of 1 was used to inoculate 25 ml of medium 1 or 2 in a 250 ml Erlenmeyer flask (see Table 5). The samples were then incubated in a humid shaker (85% relative atmospheric humidity) at 200 rpm at 30° C. for 48 hours. The lysine concentration in the medium was determined by means of HPLC. In all cases, approximately equal amounts of lysine were produced.

[0271] The resulting lysine-containing fermentation broth was processed as described in Example 1c.2) to produce extrudates.

Embodiment 3

[0273] Corynebacterium glutamicum (ATCC13032lysC fbr ) in the shake flask test (shake flask 1+2) using the corn meal hydrolyzate obtained according to Example II.3a. Furthermore, wheat semolina hydrolyzate (shake flask 3+4) and rye semolina hydrolyzate (shake flask 5+6) prepared analogously to Example II.3 were used in parallel.

[0274] 3.1) Preparation of inoculum

[0275] Cells were streaked on sterilized CM+CaAc agar (composition: see Table 7; 20 minutes at 121°C) and then incubated at 30°C for 48 hours. Then inoculate on fresh plates and incubate overnight at 30°C. Cells were then scraped from the plate and resuspended in saline. In each case, the OD was achieved at the optical density value at 610 nm as prepared 610 A cell suspension with a value of 0.5 was inoculated in 23 ml of culture medium in a 250 ml Erlenmeyer shake flask (see Table 8).

[0276] Table 7: Composition of CM+CaAc agar plates

[0277] concentration

Element

10.0g / l

D-gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com