Purification method of technical grade dimethoxym ethane

A purification method, methylal technology, applied in the field of industrial-grade methylal purification, can solve the problems of high content, huge equipment, and the need for a large amount of nitrogen to regenerate the extraction agent, and achieve the effect of simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

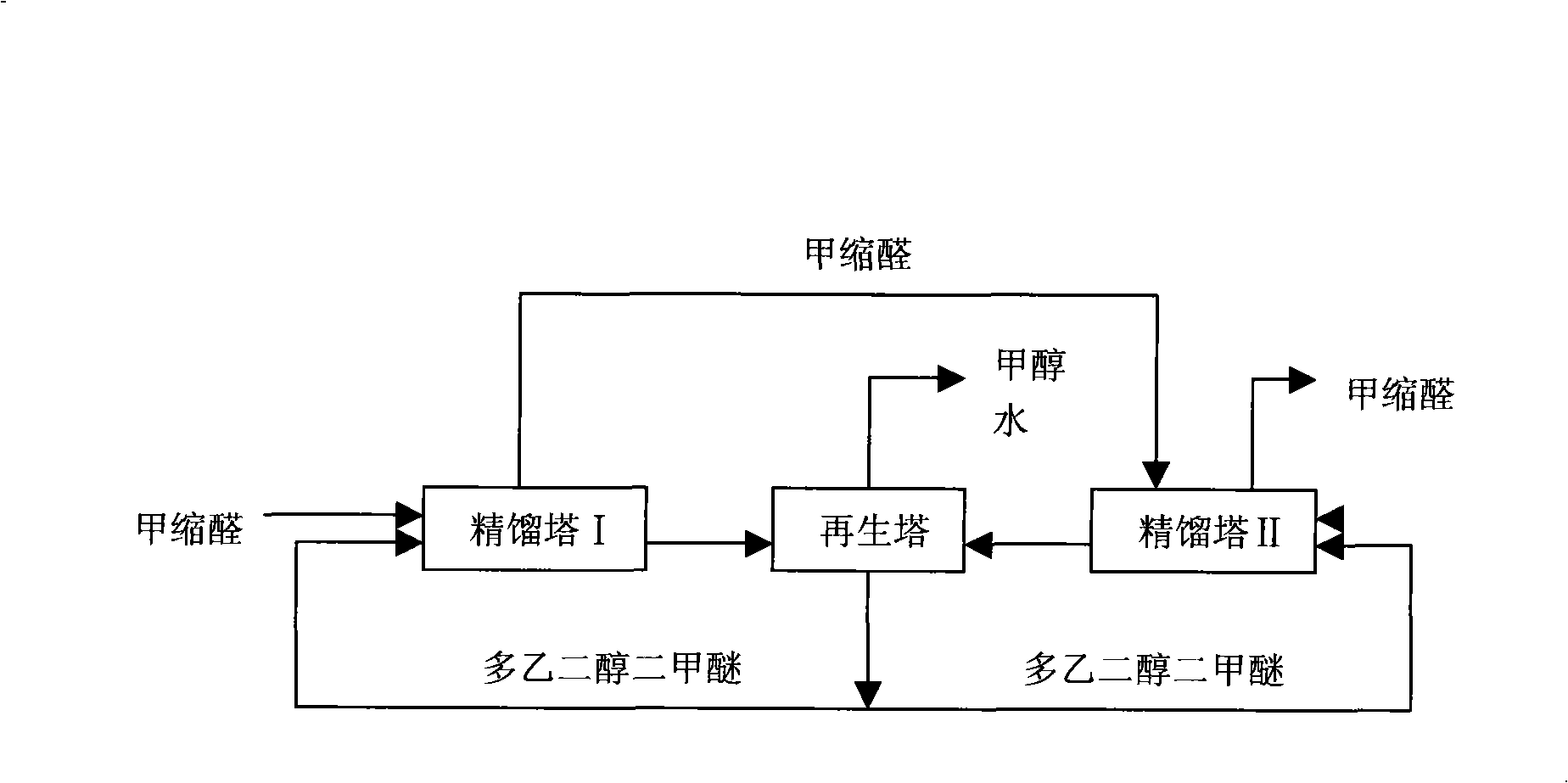

Method used

Image

Examples

example 1

[0024] Add 570g of methylal (0.3% of water, 4.0% of methanol) and 170g of polyethylene glycol dimethyl ether into a 1000ml three-necked flask equipped with a φ20×1000 packed tower and a rectifying head, heat up, and operate under total reflux to the tower The top is stable at 42°C, the temperature of the tower bottom is stable at 48°C, and the reflux ratio is adjusted to 4:1. First collect the former fraction with a top temperature lower than 42°C, and then collect the methylal fraction at 42-42.5°C. When the kettle temperature starts to rise , increase the reflux ratio to 6:1, until the temperature of the kettle rises to 60°C, collect 459g of the methylal product, and analyze the purity of the methylal by gas chromatography to 99.02%; After mixing 80g of dimethyl ether, add it to a 1000ml three-necked flask with a φ20×1000 packed tower and a rectifying head, heat up, and operate the total reflux until the top of the tower is stable at 42°C, the temperature of the bottom of the...

example 2

[0026] The used polyethylene glycol dimethyl ether is regenerated on a rectification tower with φ20×600 packing, and the methylal entrained in the polyethylene glycol dimethyl ether is first steamed under normal pressure, and the top temperature is controlled to be less than 43°C, and the reflux ratio 3:1, collect methylal, the purity is 95.8%; then control the top temperature at 64-65°C, the reflux ratio is 3:1, collect the methanol fraction, the purity is 96.3%; increase the temperature of the kettle to 130°C, collect the residual methanol and water , and slowly switch to a vacuum of -0.09MPa to remove trace impurities in polyethylene glycol dimethyl ether.

[0027] Add 570g of methylal (0.3% of water, 4.0% of methanol) and 170g of regenerated polyethylene glycol dimethyl ether into a 1000ml three-necked flask equipped with a φ20×1000 packed tower and a rectifying head, heat up and operate under full reflux Until the top of the tower is stable at 42°C, the temperature of the...

example 3

[0029] In the 2m with φ300×10000 packed tower 3Add 1100kg of methylal (0.2% of water content, 4.7% of methanol) and 300kg of polyethylene glycol dimethyl ether into the rectification kettle respectively, heat up and operate the total reflux until the top of the tower is stable at 42°C, and the temperature of the tower bottom is stable at 48°C , adjust the reflux ratio to 4:1, first collect the front fraction whose top temperature is less than 42°C, then collect the methylal fraction at 42-42.5°C, when the kettle temperature starts to rise, increase the reflux ratio to 6:1, to the kettle temperature When the temperature rises to 60°C, 913kg of methylal product is collected, and the purity of methylal is 89.9% according to gas chromatography analysis; then 910kg of methylal with a content of 89.9% and 270kg of polyethylene glycol dimethyl ether are mixed and added to a φ300×10000 packed tower 2m 3 In the rectification kettle, heat up the temperature, operate the total reflux un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com