Preparation of amphiphilic copolymer self-assembled micelle wedding agent

A copolymer and amphiphilic technology, which is applied in the field of preparation of amphiphilic copolymer self-assembled micelle emulsifiers, can solve the problems of difficult environmental responsiveness of particle emulsifiers, and achieve the effect of increasing the application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

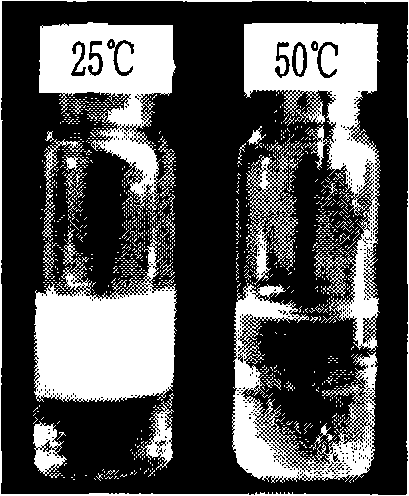

Image

Examples

Embodiment 1

[0031] (1) Preparation of amphiphilic copolymer

[0032] An amphiphilic copolymer poly(styrene-alt-maleic anhydride) with alternating structure was synthesized by radical precipitation polymerization. Weigh styrene 2.08g (0.02mol), maleic anhydride 1.96g (0.02mol), initiator azobisisobutyronitrile 0.020g (0.00012mol, calculated by 0.3% of the total molar weight of the reaction monomer) in 28mL toluene , filled with nitrogen for 20 minutes, reacted at 65°C for 12h, filtered off the toluene, dissolved in 15mL of dimethylformamide, precipitated in ether 8 times the volume of dimethylformamide, filtered, and dried in vacuo at 30°C. The product was dissolved in dimethylformamide, precipitated, filtered and dried. Repeat the above steps three times to obtain a pure amphiphilic alternating copolymer.

[0033] (2) Preparation of amphiphilic copolymer micellar emulsifier

[0034] Dissolve the copolymer obtained in (1) in dimethylformamide to make a solution with a mass concentration...

Embodiment 2

[0038] (1) The preparation of amphiphilic copolymer is the same as Example 1.

[0039] (2) The preparation of amphiphilic copolymer micelle emulsifier is the same as Example 1.

[0040] (3) Emulsion preparation

[0041] Take 3mL of the dispersed emulsifier solution described in step (2), add sodium chloride and adjust its concentration in the micellar aqueous solution, and take an equal volume of toluene, and homogenize it for 2min at a speed of 15000 rpm to obtain extremely stable Microemulsions, such polyelectrolytes can greatly improve the emulsification effect by adding small molecule electrolytes (such as sodium chloride).

Embodiment 3

[0043] (1) Preparation of amphiphilic copolymer

[0044] Synthesis of poly(maleic anhydride-co-styrene-co-(4-methyl-7-p-vinylbenzylideneoxycoumarin)) with alternating polymerization propensity. Weigh maleic anhydride 2.352g (0.024mol), styrene 1.56g (0.015mol), 4-methyl-7-p-vinylbenzylideneoxycoumarin 1.33g (0.005mol), initiator azo Diisobutyronitrile 0.072g (0.00044mol, 1.0% of the total molar weight of monomers) in 25mL dioxane, filled with nitrogen for 50 minutes, reacted at 65°C for 8h, in methanol 8 times the volume of dioxane / water (volume ratio: 1:1) mixed solvent, filtered, and vacuum dried at 30°C. The product was dissolved in THF, precipitated, filtered and dried. Repeat the above steps three times to obtain a pure amphiphilic copolymer with alternating structure tendency.

[0045] (2) Preparation of amphiphilic copolymer micellar emulsifier

[0046] The obtained copolymer was dissolved in dioxane to form a solution with a mass concentration of 5%, and gradually...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com