Preparation of pigment particle agglutination dispersion, resin composition and color filter

An agglomerate and color filter technology, applied in the treatment of dyed high molecular organic compounds, dyed low molecular organic compounds, nanotechnology for materials and surface science, etc., can solve difficult dispersion, complicated operation, low viscosity, etc. problem, to achieve the effect of high contrast, excellent dispersion, and high color purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0473] [Preparation of aqueous dispersion of organic nano-pigment particles]

[0474] C.I. Pigment Red 254 (45 parts by mass) and polyvinylpyrrolidone (K-25, manufactured by Wako Pure Chemical Industries, Ltd., 90 parts by mass) were added to dimethyl sulfoxide (DMSO) (953 parts by mass), and stirred . A 28% by mass methanol solution (30 parts by volume) of sodium methoxide was added to this solution to prepare a pigment solution A. Separately, water (4000 parts by mass) was prepared as a pigment insoluble solvent B.

[0475] While stirring the insoluble solvent B of the above-mentioned pigment at 30° C. with a GK-0222-10 type ramond stirrer (trade name) manufactured by Fujisawa Pharmaceutical Industry Co., Ltd. at a speed of 500 rpm, the NP- KX-500 large-capacity non-pulsating pump (trade name) injects the above-mentioned pigment solution A into the insoluble solvent B of the pigment at a flow rate of 100ml / min, and the injection time is 4 minutes and 4 seconds, so that the...

Embodiment 2

[0497] The same operation as in Example 1 was carried out, except that the nonionic low molecular weight compound in Example 1 was replaced with nonionic 2-propyl valerate. The obtained organic nanoparticle non-aqueous dispersion liquid was referred to as pigment dispersion composition B. The same evaluation test as in Example 1 was performed on the pigment dispersion composition B, and the results are shown in Table 1.

Embodiment 3

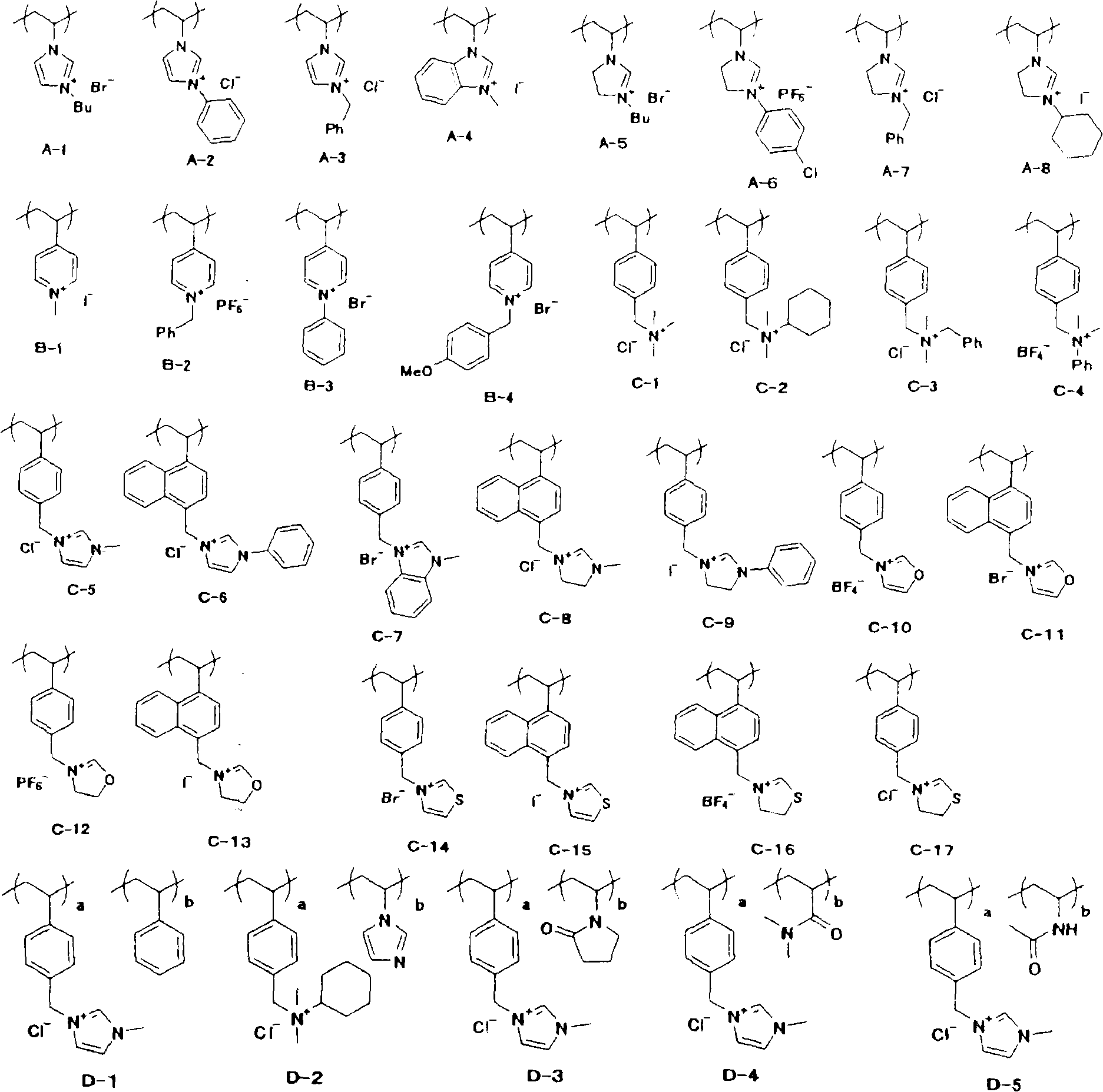

[0499] The same operation as in Example 1 was carried out, except that the non-ionic polymer compound in Example 1 was replaced with non-ionic C-10. The obtained organic nanoparticle non-aqueous dispersion liquid was referred to as pigment dispersion composition C. The same evaluation test as in Example 1 was performed on the pigment dispersion composition C, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com