Reduction method for processing waste plastic and system thereof

A technology for waste plastics and pretreatment, which is used in plastic recycling, coke oven heating, preparation of liquid hydrocarbon mixtures, etc. It can solve the problems of high noise and high energy consumption, and achieve strong anti-interference performance, simple operation and good start-up performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

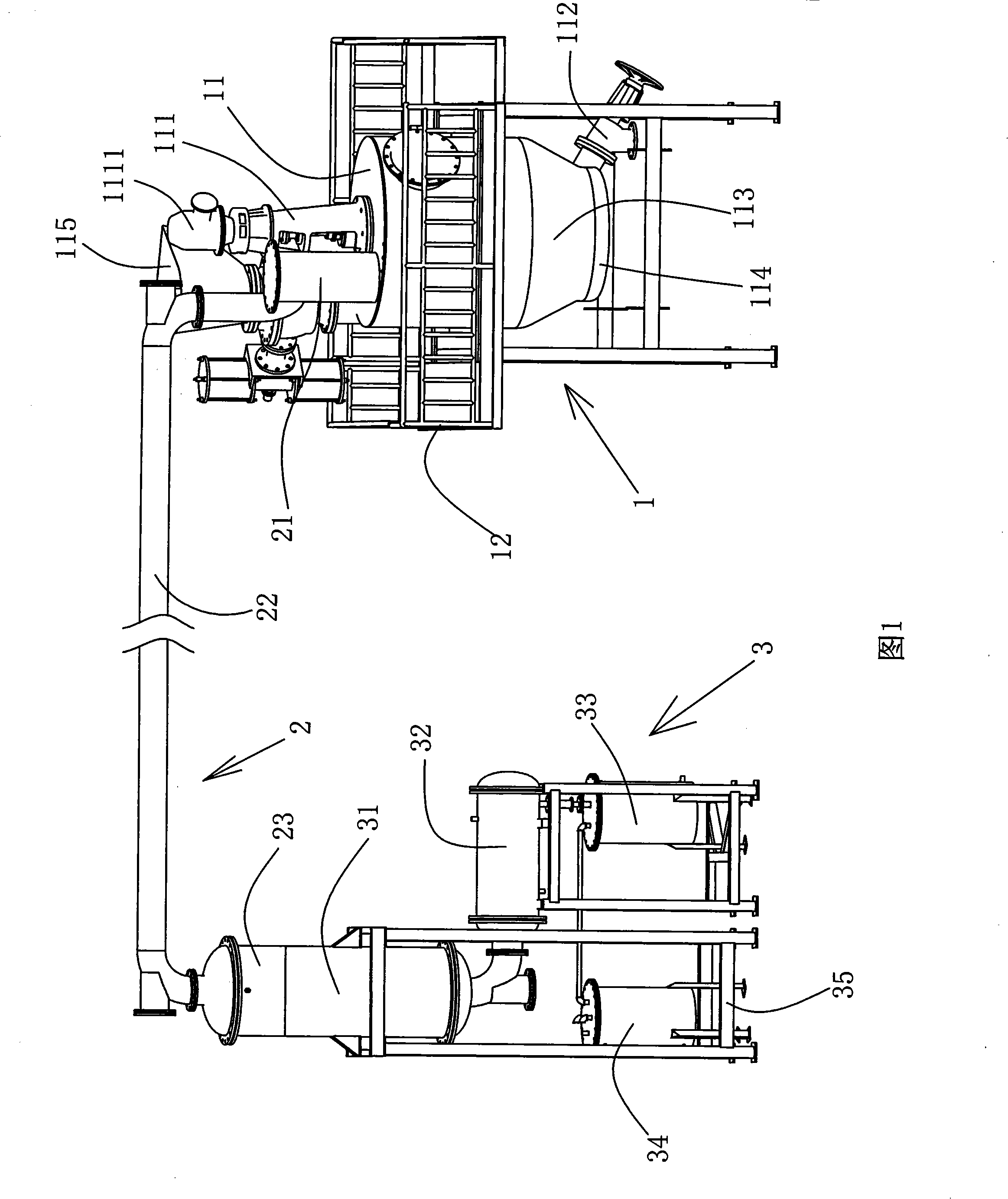

[0028] In the figure: 1. Heating cracking part;

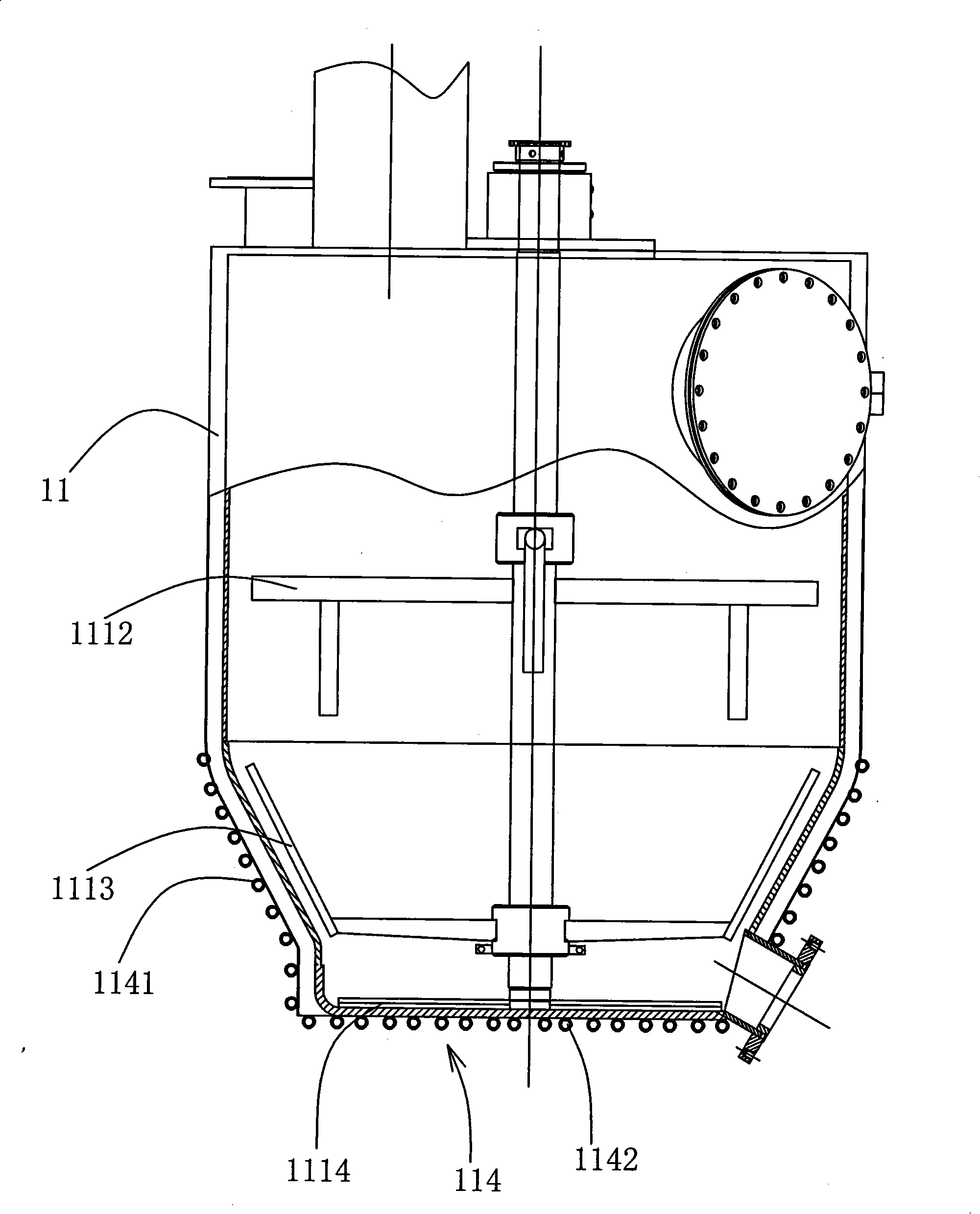

[0029] 11. Cracking kettle;

[0030] 111. Stirring device; 1111. Stirring motor;

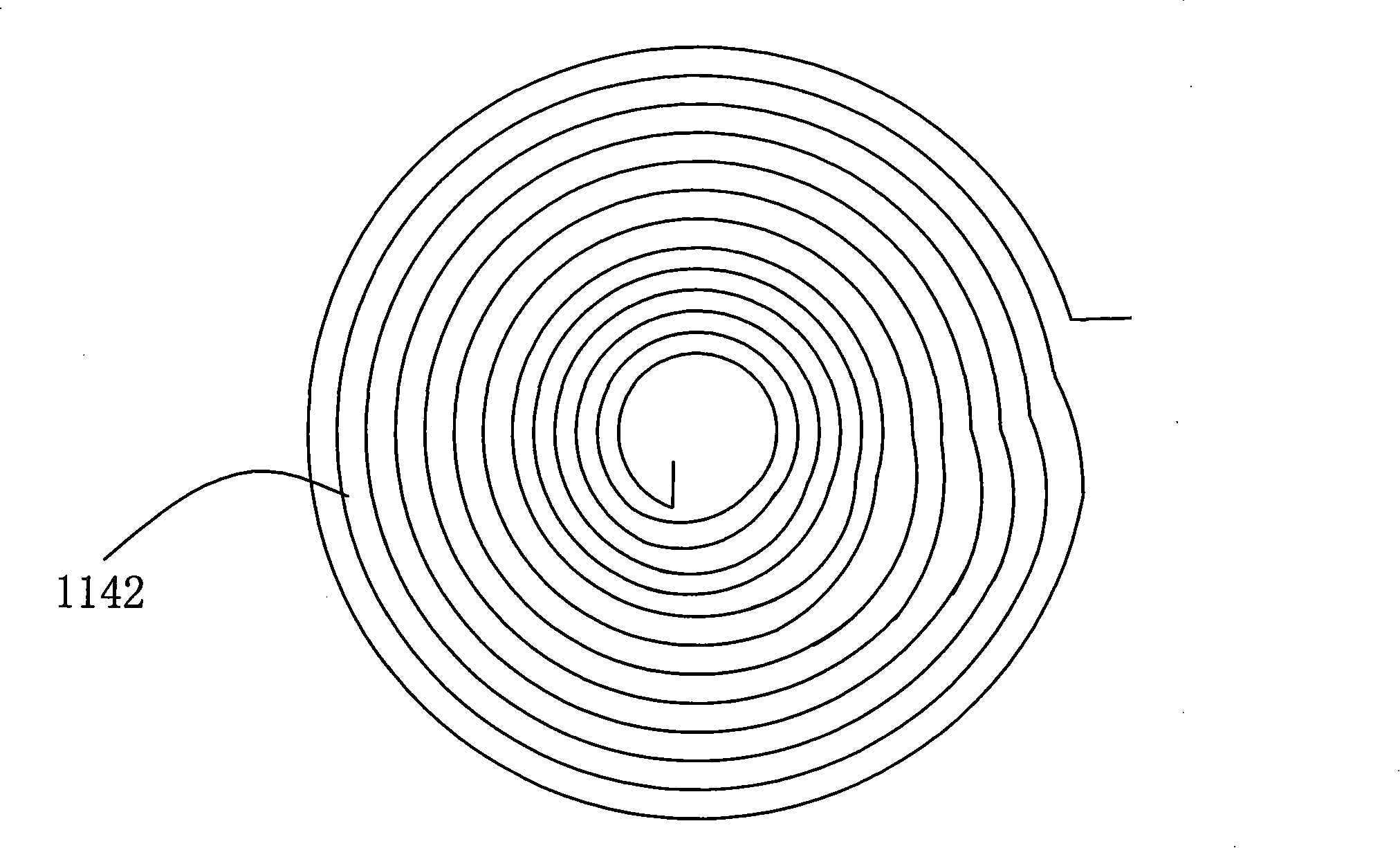

[0031] 112, slag outlet; 113, cone bottom; 114, IGBT super audio heater;

[0032] 115. Feed inlet;

[0033] 12. Operating table;

[0034] 2. Catalytic cracking unit;

[0035] 21. Catalytic tower; 22. Connecting pipeline; 23. Second catalytic section;

[0036] 3. Cooling recovery department;

[0037] 31. First cooler; 32. Second cooler; 33. Oil storage tank; 34. Gas-water separation tank;

[0038] 35. Cooling recovery support.

[0039] See Figure 1 and figure 2 , FIG. 1 is a schematic structural diagram of an embodiment of the system part of the present invention. figure 2 It is a schematic diagram of the partial sectional structure of the cracking kettle in Fig. 1 . Figure 1 and figure 2What is disclosed is a system for processing waste plastics, generally speaking, it includes a heating cracking unit 1 for thermally cracking waste pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com