Method for manufacturing magnetizing lead acid accumulator without vulcanizing

A lead-acid battery and a manufacturing method technology, applied in the directions of lead-acid battery, lead-acid battery construction, final product manufacturing, etc., can solve the problems of reducing the effective area of the plate reaction, speeding up the production and recycling cycle rate, endangering personal and property safety, etc. , to avoid irreversible and thermal runaway phenomena, reduce repeated purchase and maintenance costs, extend service life and the effect of scrapping cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

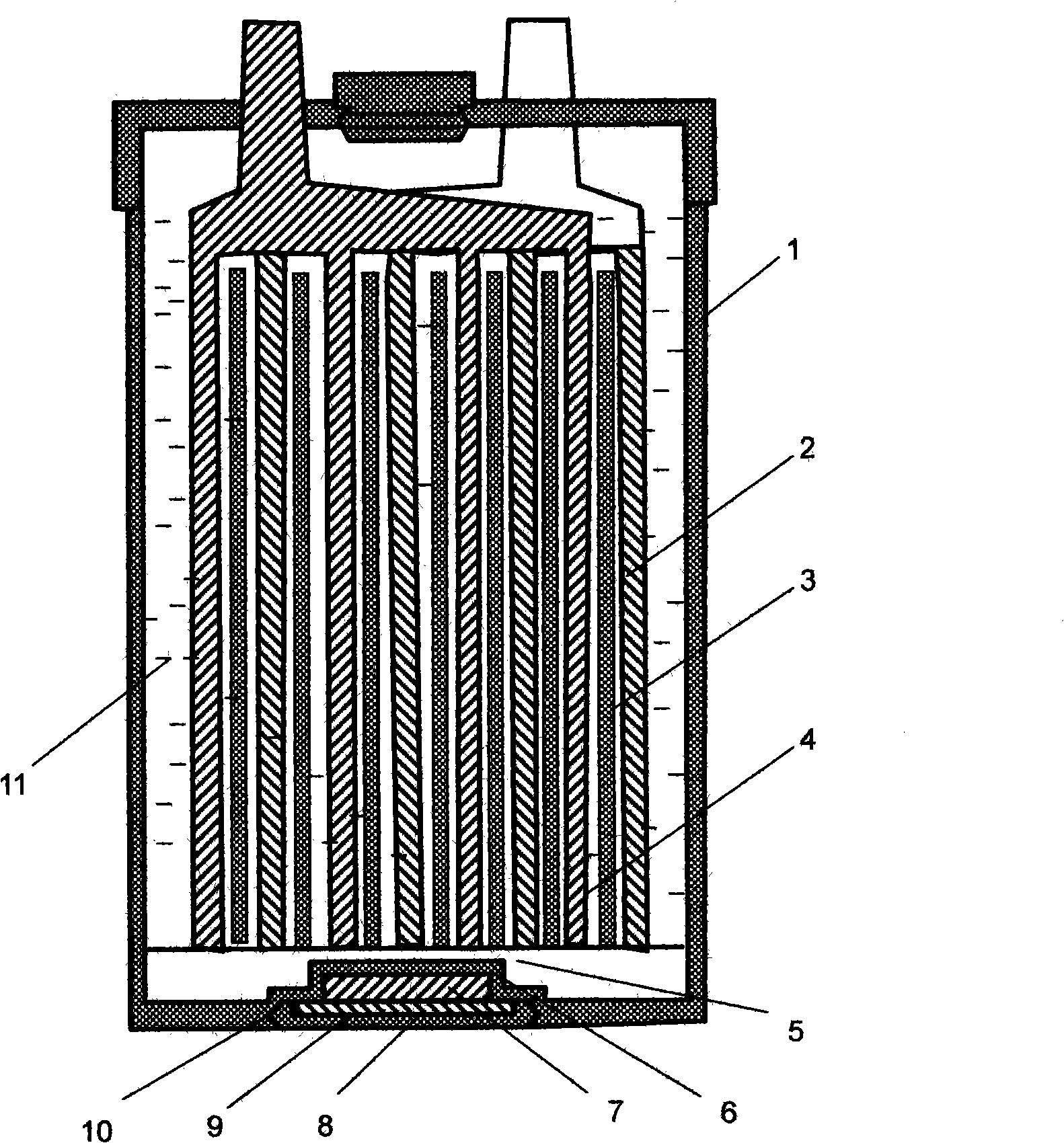

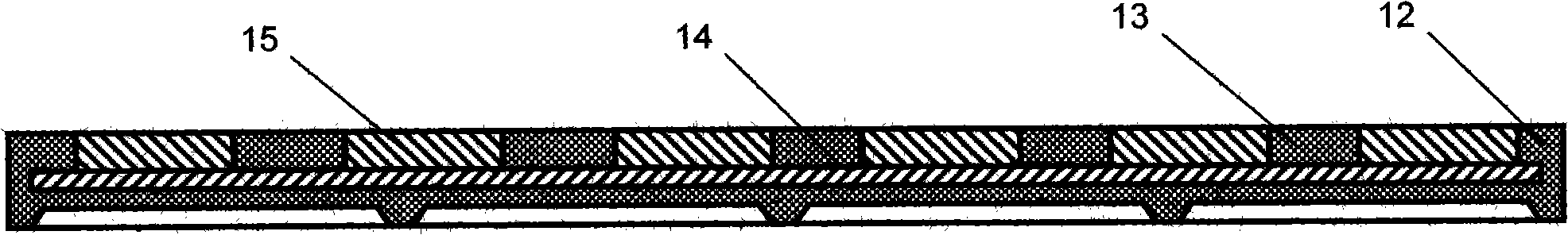

[0037] figure 1 It is a structural cross-sectional view of a unit group of the newly produced magnetized storage battery of the present invention. In the battery casing (1) in the figure, there are positive plate (2) and negative plate (4) interpenetrated with each other, a separator (3) is arranged between the positive plate (2) and negative plate (4), and the positive plate (2), negative plate (4), separator (3) are all soaked in electrolyte (11), and it is basically the same with existing storage battery structure; 1) is provided with a fixed nest (6) of a magnetic field source sunken into the storage battery, and in the fixed nest (6) is provided with a magnetic field source (7). The magnetic field source (7) is a circular sheet-shaped NdFeB magnet. The magnetic force lines tend to be parallel to the moving direction of the directional current on the pole plate, and a ferromagnetic magnetic field shielding layer (8) is attached on the outer surface of the magnet, and a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com