Borohydride metallocene complex of a lanthanide, catalytic system including said complex, polymerization method using same and ethylene/butadiene copolymer obtained using said method

A metallocene complex, lanthanide technology, applied to lanthanide borohydride metallocene complexes, catalytic systems comprising said complexes, polymerization using the same complexes and using said obtained ethylene- In the field of butadiene copolymers, it is possible to solve problems such as the description of copolymerization of olefins and conjugated dienes without the use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] All of the following examples were carried out under argon atmosphere with pre-drying of the used solvents by reaction with sodium followed by distillation or passing through 3 Angstrom molecular sieves while flushing with argon.

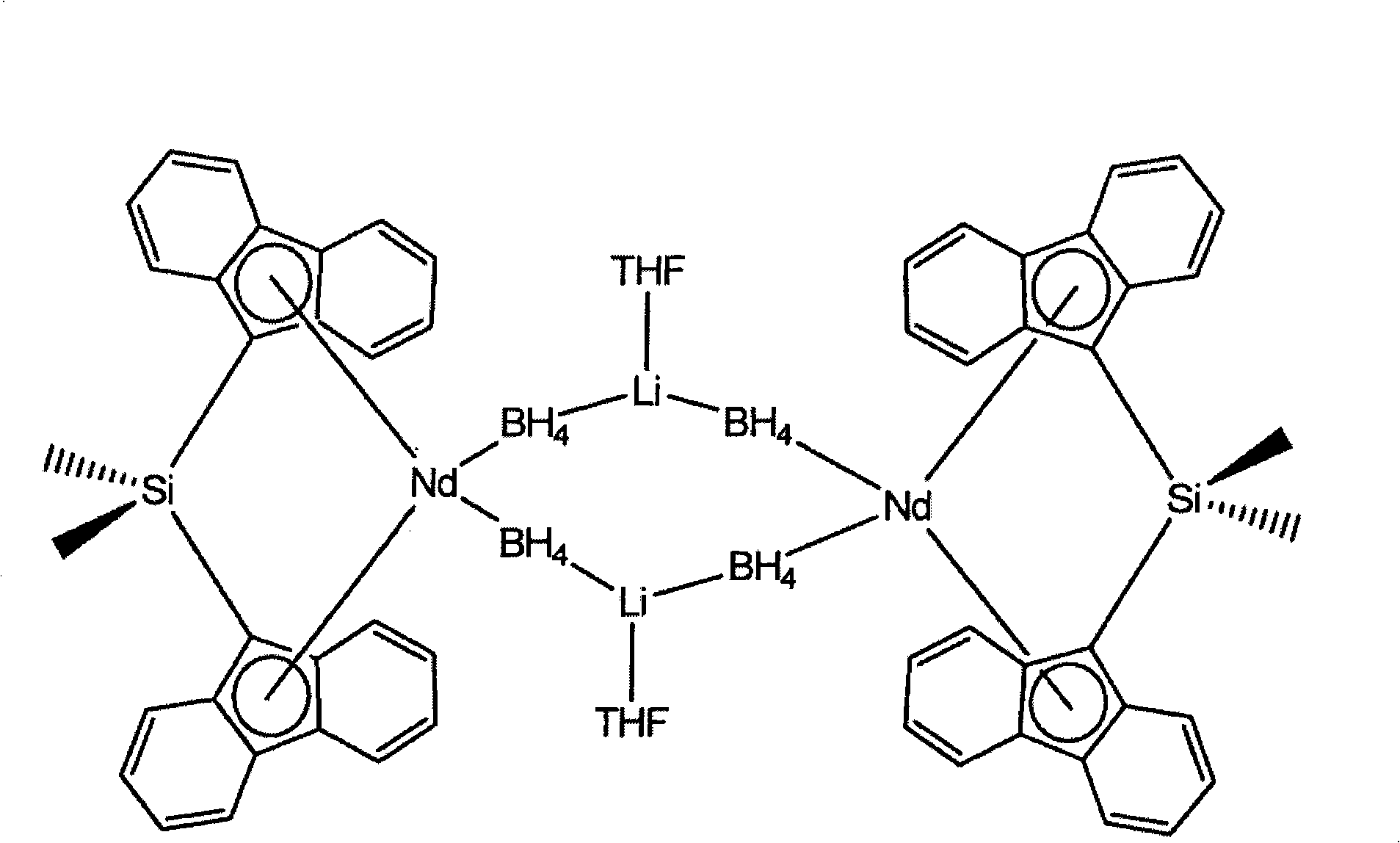

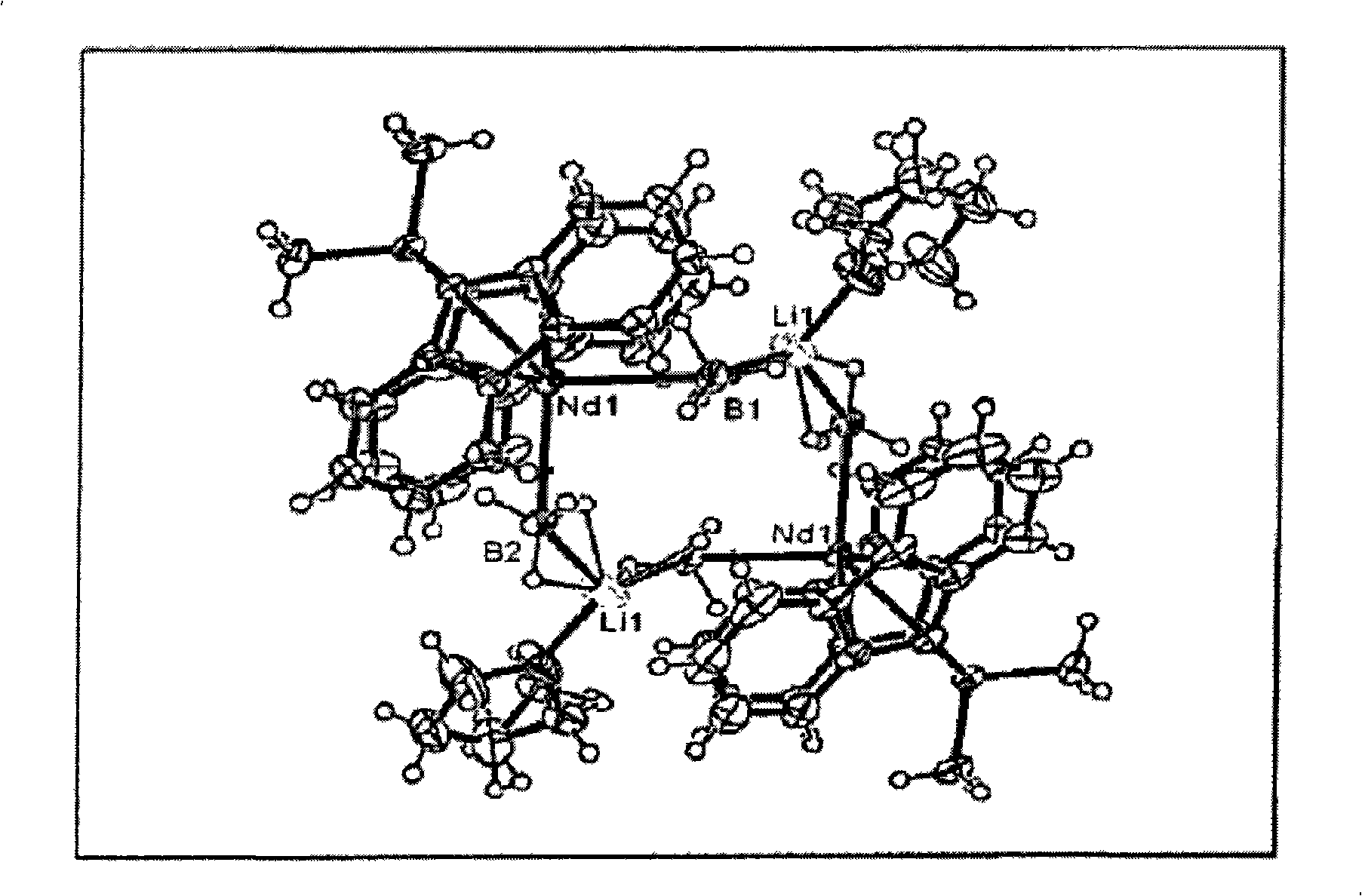

[0085] All the metallocene complexes synthesized below are at 22°C in d 8 - Passed at 300MHz using a "Bruker DRX 300" spectrometer in THF 1 The analysis was carried out by H NMR and, furthermore, for the hydroboration complexes according to the present invention, by the X-ray diffraction technique described in Additional Annex 1.

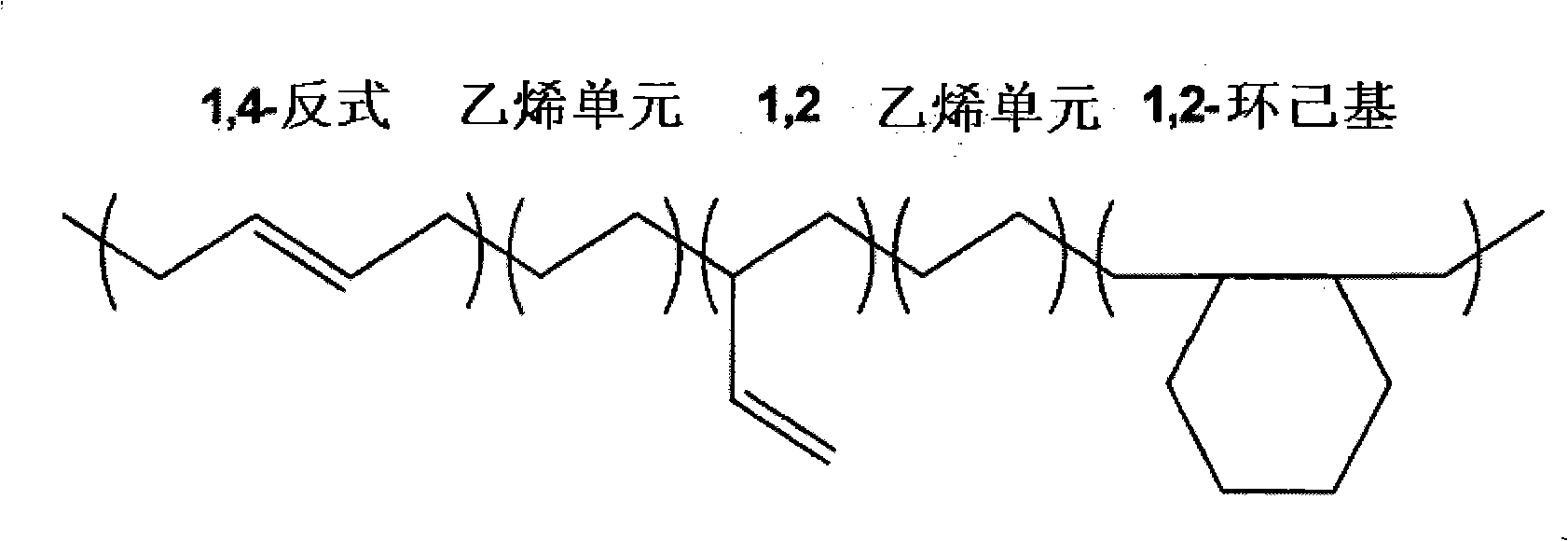

[0086] The microstructure of each copolymer obtained in these examples was obtained by 1 H NMR and 13 C NMR technique determination. For this, a "Bruker DRX 400" spectrometer was used at 400 MHz for 1 H NMR technique at 100.6MHz for 13 C NMR techniques. Spectra were collected at a temperature of 363K using a 5 mm "QNP" probe. A tetrachloroethylene / perdeuterated benzene mixture (2:1 by volume) was used as sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com