Nano-scale chitosan and latex coblended antibiont and preparation method thereof

A chitosan and nano-scale technology, which is applied in the field of nano-scale chitosan and latex blended antibacterial substances and its preparation, can solve the problems of chitosan not showing antibacterial properties, long antibacterial latex time, and human health hazards , to achieve the effect of easy mixing with latex, solving potential hazards, and long solution time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

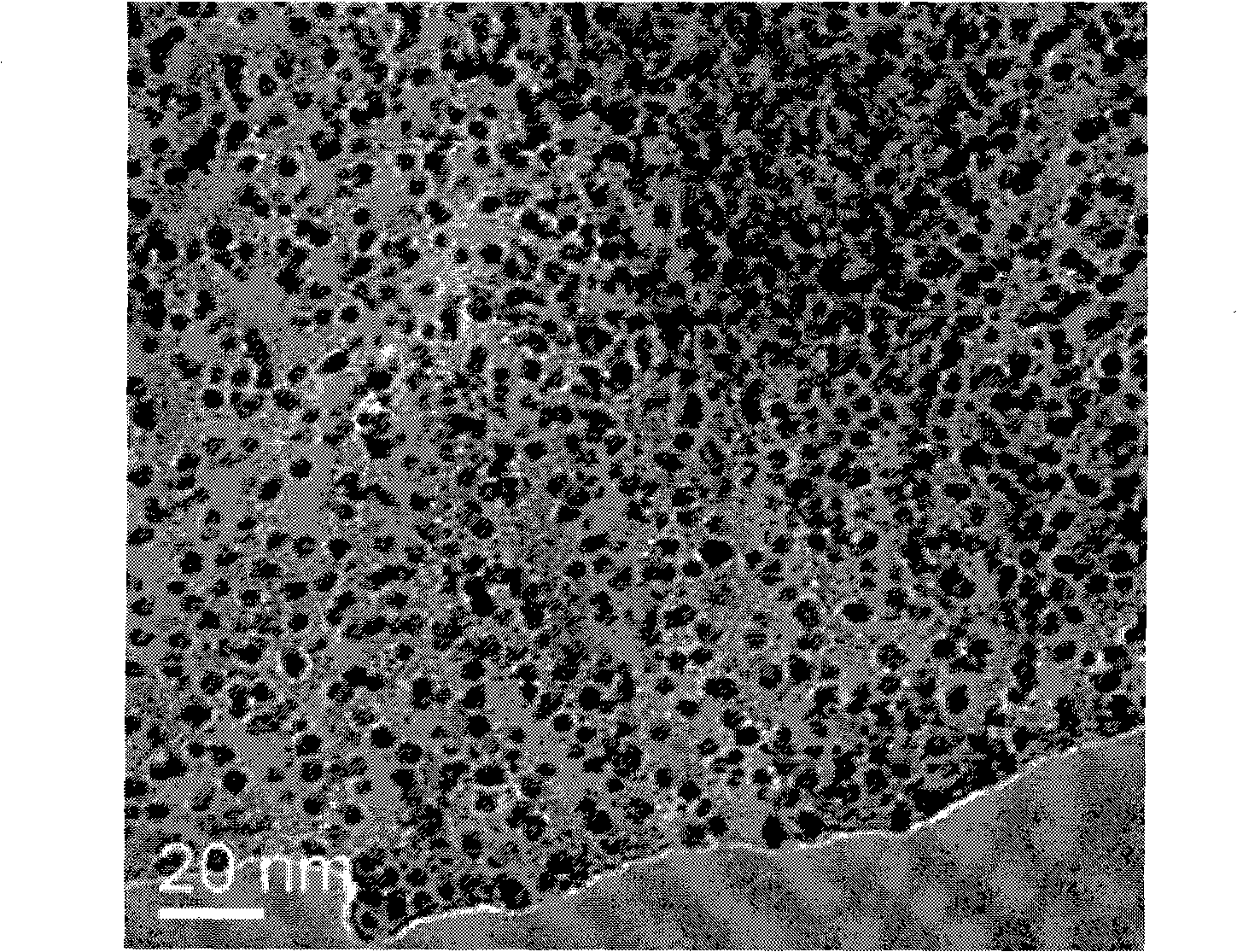

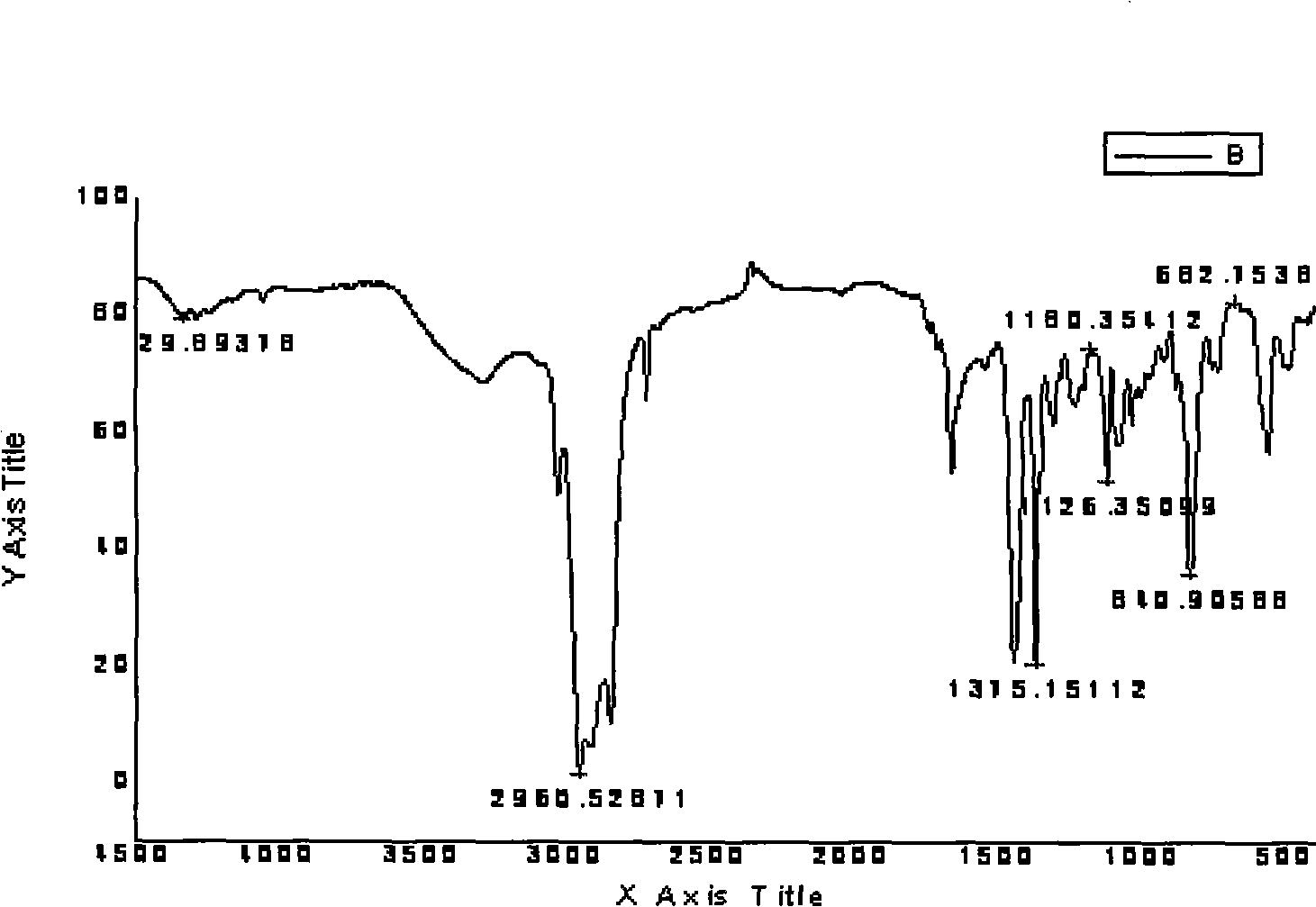

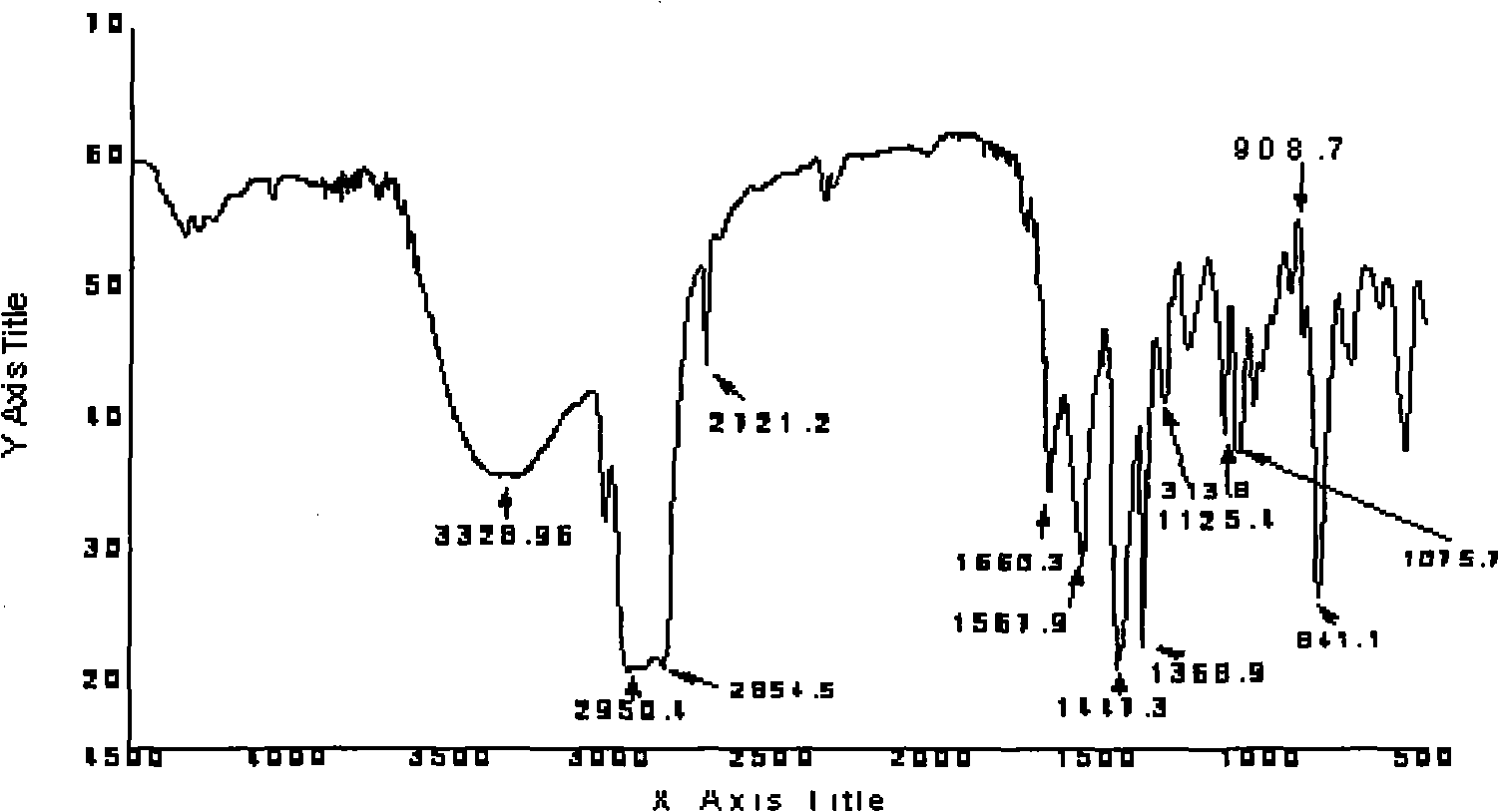

Image

Examples

Embodiment 1

[0037](1) 0.04g chitosan was dissolved in 20ml 2% acetic acid solution, placed on a magnetic stirrer and stirred for 40min;

[0038] (2) After standing for 5 minutes to defoam, add 3.35 mg of dispersant sodium polyphosphate until the solution is milky white;

[0039] (3) Use sodium hydroxide solution to adjust the pH of the solution to 5.0-6.0, and then use ammonia water to adjust the pH to 8.5-9.0;

[0040] (4) Filter 10ml of latex with 80 mesh molecular sieves, pour it into a three-hole flask, and use an electric stirrer to stir for 10min at a speed of 60r / min to remove the ammonia therein;

[0041] (5) pour 10ml into the nanoscale chitosan solution prepared in the third step, feed nitrogen;

[0042] (6) Stir for 3h at a rotating speed of 60r / min;

[0043] (7) Take it out after the stirring is completed, and form a film after standing for 48 hours.

[0044] Obtained by the above-mentioned preparation method to be made up of nano-scale chitosan, latex and sodium polyphosph...

Embodiment 2

[0046] According to the processing method of embodiment 1, the difference of embodiment 2 is: the ratio of the molar mass of nanoscale chitosan and latex is 1: 5; Be dissolved in the acetic acid solution of 20ml 2%; Stir under the rotating speed of 100r / min 2h. The molar mass ratio of nanoscale chitosan and latex obtained is: 1:5~2:1; the ratio of molar mass of sodium polyphosphate to chitosan is: 1:200~1:50 nanoscale chitosan Antimicrobial blend of sugar and latex.

Embodiment 3

[0048] According to the processing method of embodiment 1, the difference of embodiment 3 is: the ratio of the molar mass of nanoscale chitosan and latex is 2: 1; Be dissolved in the acetic acid solution of 20ml 2%; Stir under the rotating speed of 80r / min 4h. The molar mass ratio of nanoscale chitosan and latex obtained is: 1:5~2:1; the ratio of molar mass of sodium polyphosphate to chitosan is: 1:200~1:50 nanoscale chitosan Antimicrobial blend of sugar and latex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com