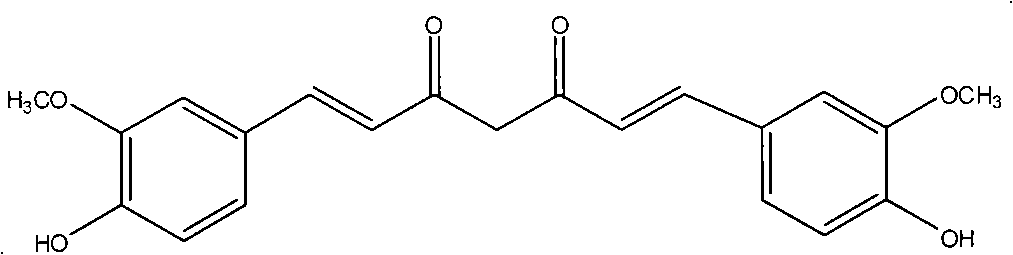

Preparation for effective component of turmeric

An effective component, turmeric technology, applied in the field of extraction and preparation of effective components of turmeric, can solve the problems of inability to produce on a large scale, low product purity, poor reproducibility, etc. , Highly reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

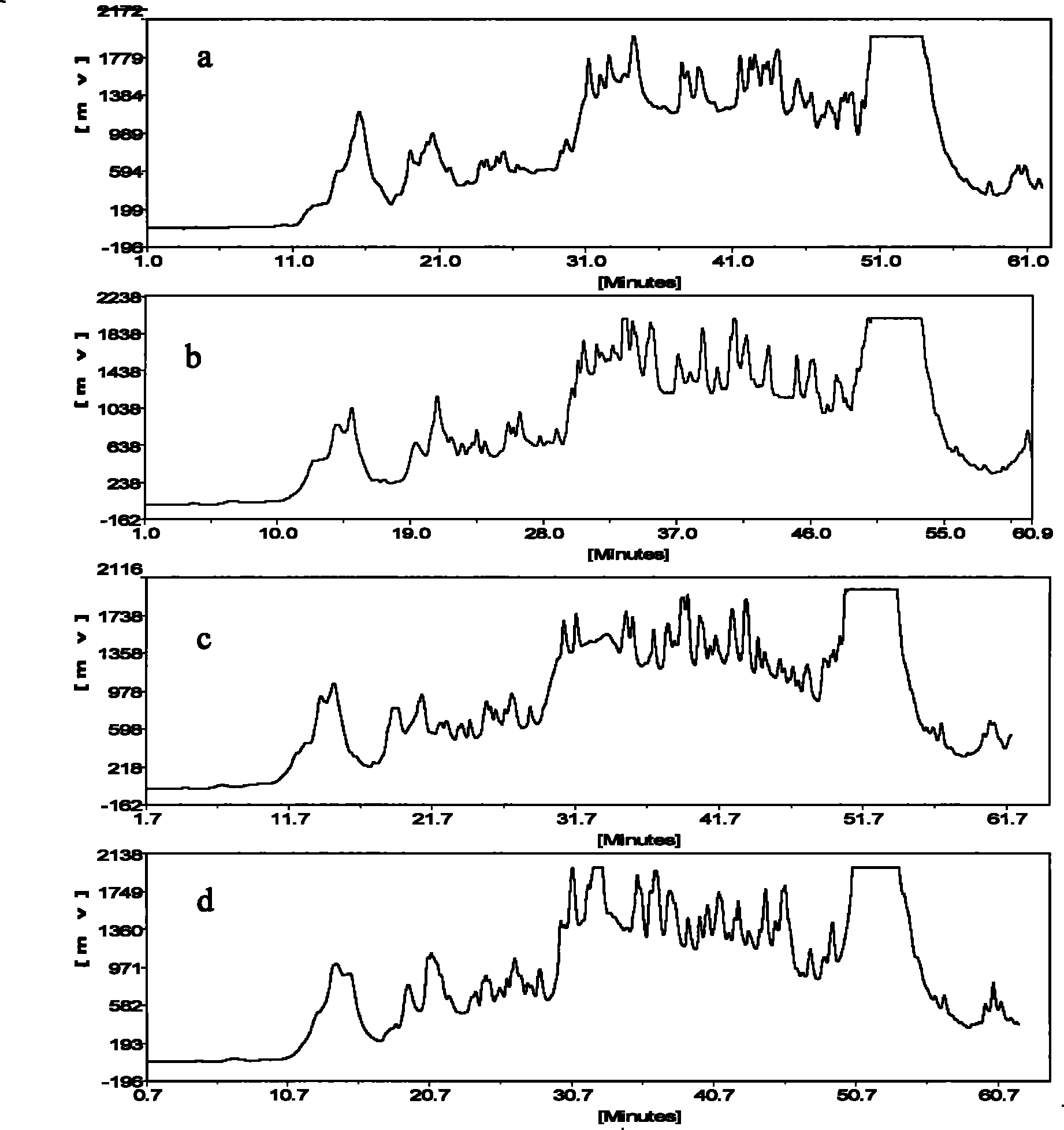

Method used

Image

Examples

Embodiment 1

[0019] Grind the original medicinal material of turmeric, weigh 1 kg quantitatively, put it in a 20-liter extraction tank, add 10 liters of 95% ethanol to soak for 1 day, filter, save the filtrate for later use, add 10 liters of 95% ethanol to the filter residue and soak for 1 day, filter , the filtrate was combined with the first time, and the filter residue was discarded. The extract was concentrated to 150 ml by rotary evaporation to obtain the alcohol-extracted fraction of curcuma.

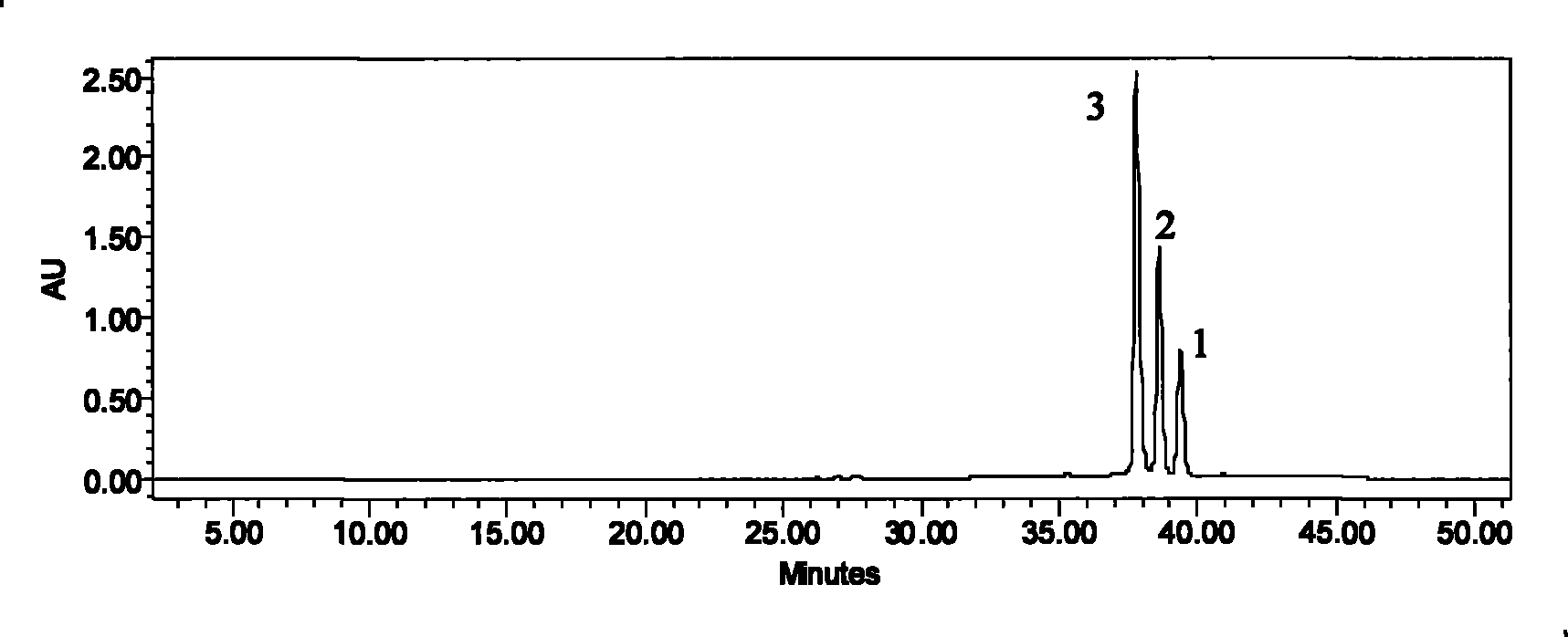

[0020] Load 10 L of processed Rohm and Haas XAD-4 macroporous resin into the macroporous resin chromatography system, and dry-load the curcumin alcohol extraction fraction on the macroporous resin chromatography column. First use 4 times column volume 40L 50% ethanol to elute the column body, discard the eluate, then use 4 times column volume 40L 80% ethanol to elute, save the eluate, and concentrate to a solid content of 0.3 g / ml, pass 0.22 micron filter membrane, obtains 50 milliliters of t...

Embodiment 2

[0031] Grind the original turmeric medicinal material, weigh 0.5 kg quantitatively, put it in a 10-liter extraction tank, add 6 liters of 70% ethanol to soak for 2 days, filter, save the filtrate for later use, add 6 liters of 70% ethanol to the filter residue and soak for 1 day, filter , the filtrate was combined with the first time, and the filter residue was discarded. The extract was concentrated to 70 ml by rotary evaporation to obtain the alcohol-extracted fraction of curcuma.

[0032] Put 5 L of processed Rohm and Haas XAD-4 macroporous resin into the macroporous resin chromatography system, and dry-load the curcumin alcohol extraction fraction on the macroporous resin chromatography column. First, the column was eluted with 6 times column volume of 30L 40% ethanol, and the eluate was discarded, then eluted with 6 times column volume of 30L 85% ethanol, and the eluate was stored and concentrated to a solid content of 0.2 g / ml. Cross 0.22 micron filter membrane, obtain ...

Embodiment 3

[0035] Grind the original medicinal material of turmeric, weigh 5 kg quantitatively, put it in a 100-liter extraction tank, add 60 liters of 80% ethanol to soak for 2 days, filter, save the filtrate for later use, add 60 liters of 80% ethanol to the filter residue and soak for 2 days, filter , the filtrate was combined with the first time, and the filter residue was discarded. The extract was concentrated by rotary evaporation to 700 ml to obtain the curcumin alcohol-extracted fraction.

[0036] Load 50 L of processed Rohm and Haas XAD-4 macroporous resin into the macroporous resin chromatography system, and dry-load the curcumin alcohol extraction fraction on the macroporous resin chromatography column. First use 3 times the column volume of 150L 60% ethanol to elute the column body, discard the eluate, and then use 3 times the column volume for 150L 95% ethanol to elute, save the eluate, and concentrate it to a solid content of 0.5 g / ml. 0.45 micron filter membrane, obtains...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com