Antifungal/antibacterial agent comprising two-step baked shell powder

A technology of antibacterial agent and powder, which is applied in the field of inorganic composite antifungal agents to achieve excellent antifungal effect and antibacterial effect, significant antifungal effect and antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

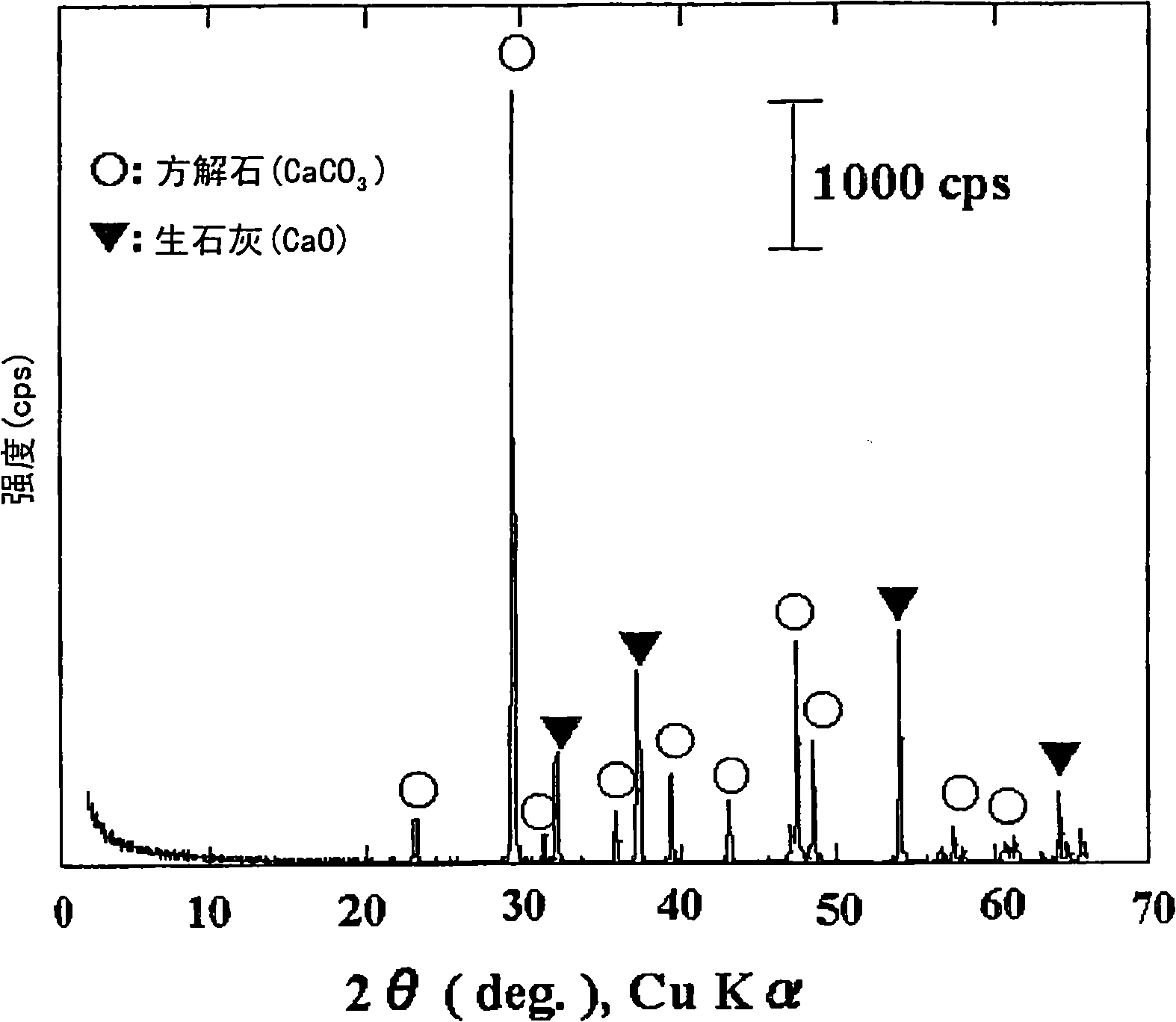

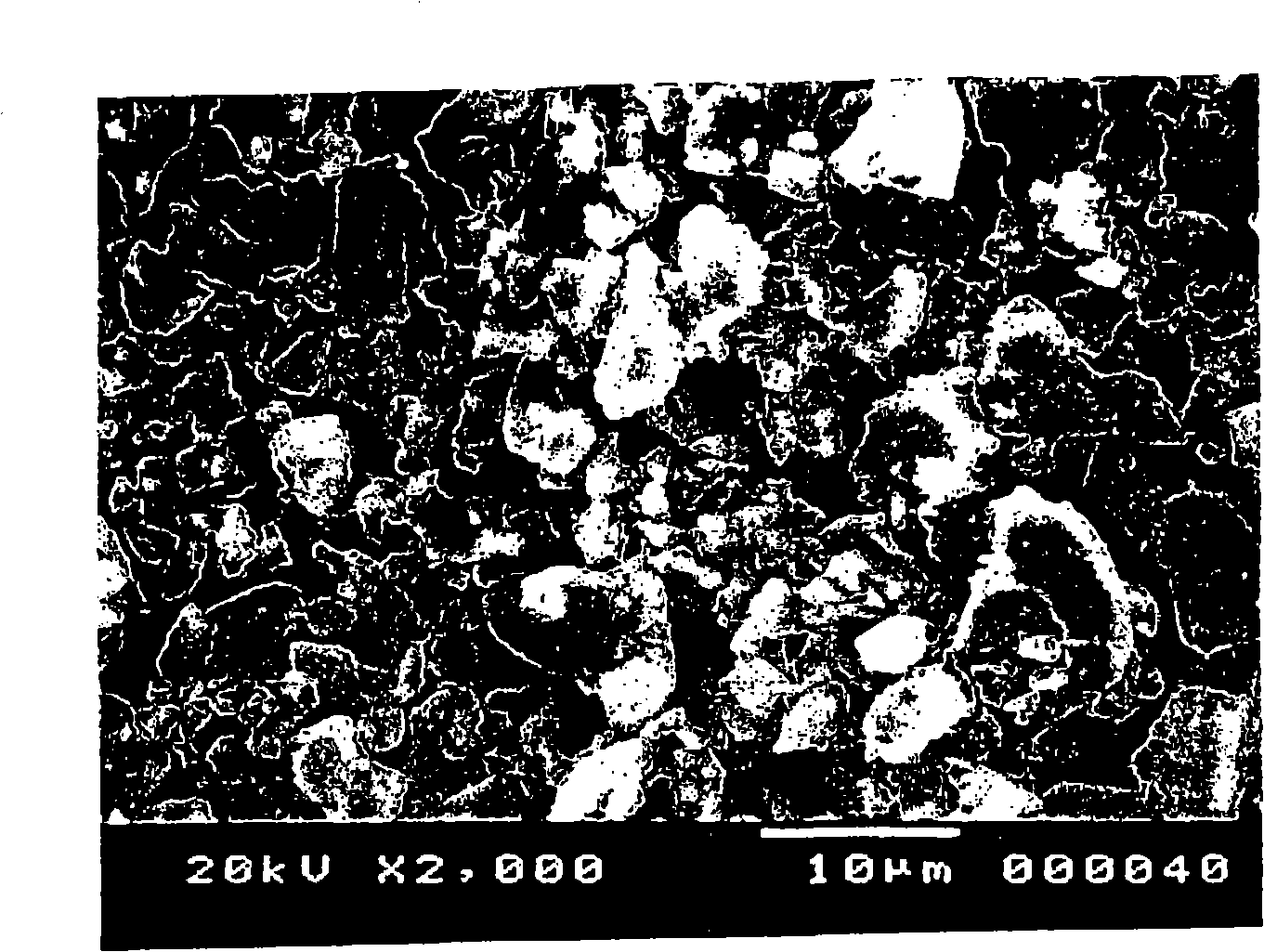

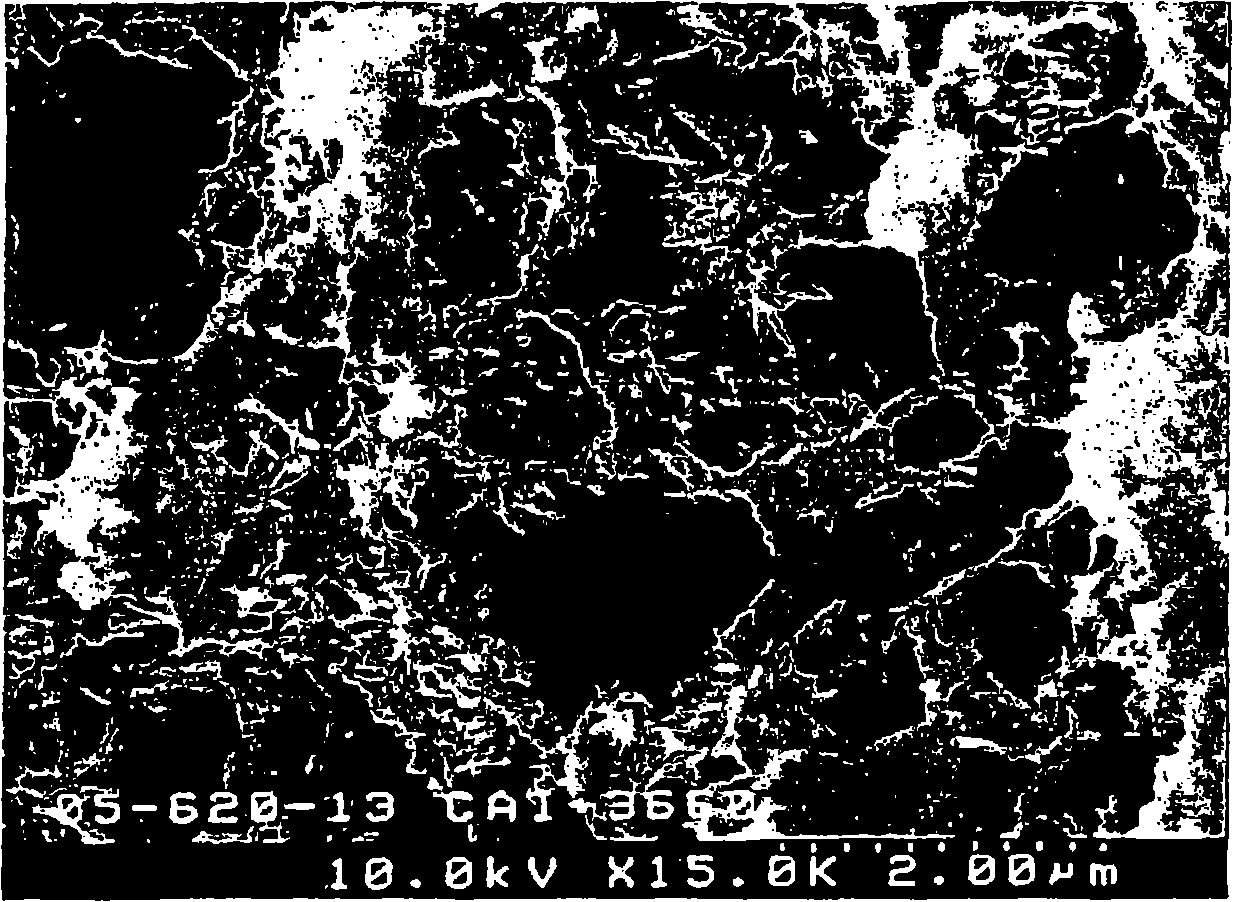

[0046] After washing and drying, the scallop shells from Lake Saroma in Hokkaido are coarsely crushed with a roller mill to an average particle size of about 5mm, and the crushed product is placed in an electric furnace at 500°C for 2 hours in a nitrogen atmosphere. once fired. Then, the baked product was subjected to secondary firing at 700° C. for 2 hours in an air atmosphere. The fired shells were pulverized with a jet mill to obtain fired shell powder having an average particle diameter of about 5 μm. The composition of the fired powder was studied by X-ray diffraction, and the results were as follows: figure 1 As shown, it was confirmed that the main component was calcite-type calcium carbonate and calcium oxide was contained. Also, the result of measuring the BET specific surface area was 27.8m 2 / g. Furthermore, the fired shell powder was observed under an electron microscope as a porous body ( figure 2 , image 3 ). Furthermore, chemical analysis of the fired s...

Embodiment 2

[0048]For the scallop shell of Example 1, burnt shell powder (sample No.1-6) is produced according to the manufacturing method shown in Table 1, and the preparation makes the fired shell powder uniform with a proportion of 0.3-1.0wt%. A test body obtained by dispersing in an FRP material. The mold resistance test was performed on this test body. The test was performed based on the MS-45 method using 45 species of fungi. The test bacteria, test conditions and evaluation methods are shown in Table 2. The test results are shown in Table 3. As shown in Table 3, the test body containing the unfired product of sample No. A1 had no antifungal effect at all. Calcium carbonate was used as the main component of the fired product mixed with sample No.A2, which was fired at a low temperature. At the beginning of the test, it had a considerable anti-mold effect, but at the end of the test, the mold grew significantly, and the anti-mold effect was not sustainable. sex. The test body of...

Embodiment 3

[0057] Washed and dried scallop shells from Mutsu Bay, Aomori Prefecture are roughly crushed with a roller mill to an average particle size of about 10mm, and the crushed product is placed in an electric furnace at 500°C under a nitrogen atmosphere. 2 hours of one firing. Then, the fired product was subjected to secondary firing at 650° C. for 3 hours in an air atmosphere. This was finely pulverized with a jet mill to obtain fired shell powder having an average particle diameter of about 7 μm. The composition of the fired powder was studied by X-ray diffraction, and the result was the same as figure 1 roughly the same result. In addition, the BET specific surface area of the calcined powder was 25.9m 2 / g. Furthermore, by electron microscopy, with figure 2 Similarly, it was observed that the calcined powder was a porous body maintaining the shell structure of the scallop, and fine particles of calcium oxide were present in the interior. Furthermore, chemical analysis ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com