Rigid and flexible composite bio-fillers for deodorization by bio trickling filtration and method for preparing same

A biological trickling filter, rigid-flexible composite technology, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem of low treatment efficiency of biological trickling filter, unfavorable microbial reproduction and survival, and odor gas interception Low rate and other problems, achieve multiple attachment growth points, improve the defects of smooth and difficult to hang film, and avoid the effect of microbial malnutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

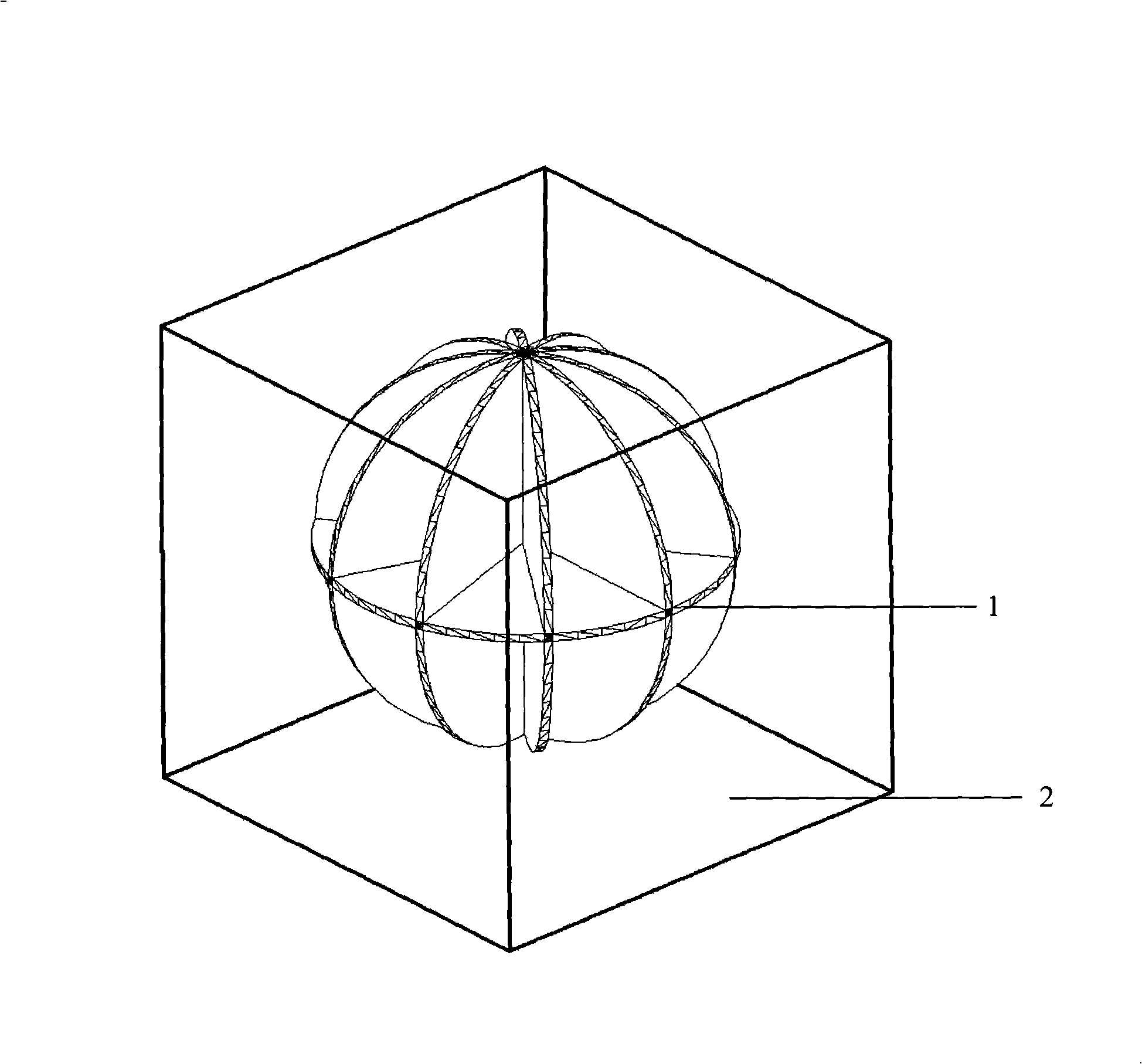

[0050] The preparation method of rigid-flexible composite biological filler for biological trickling deodorization equipment comprises the following steps:

[0051] 1) Use 0.5-5 parts by weight of dispersing lubricating liquid to moisten 1-10 parts by weight of slow-release control substances, and mix with 5-20 parts by weight of nutrients in a mixer; then use the remaining 0.5-5 parts by weight Wet 70 to 100 parts by weight of the polymer base material with a dispersing lubricating liquid of 1000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000%% of the polymer base material, and add to the mixer together with the aforementioned mixture to stir evenly, then move the mixed mixture into the mixing hopper of the injection molding machine, and extrude through the filler mold Forming to obtain a rigid polymer skeleton 1;

[0052]2) Rigid polymer skeleton 1 and 40-60 parts by weight of polyether poly...

Embodiment 1

[0056] Take by weighing 5 grams of vegetable oil, make it moisten 10 grams of diatomite, and mix the moistened diatomite with 50 grams of bone meal in a blender, then weigh 5 grams of vegetable oil and mix 700 grams of polymer base polypropylene particles gram wetted, and added to the blender and stirred with the aforementioned mixture, and then moved the blended mixture into the mixing hopper of the injection molding machine, and extruded through the filler mold to obtain 380 rigid polymer skeletons 1 . The rigid polymer framework 1 is a three-dimensional multifaceted hollow spherical structure with a diameter of 25mm. Prepare 400 grams of polyether glycerol, 400 grams of organic isocyanate, 5 grams of stannous octoate, 5 grams of triethanolamine, 10 grams of cyclopentane, 5 grams of silicon-carbon bond copolymer and 300 ml of water, mix with rigid polymer skeleton 1 and Under high-speed stirring, it is quickly added to the molding box, and reactions such as chain growth, foa...

Embodiment 2

[0059] Take by weighing 50 grams of animal oil, make it moisten 100 grams of activated carbon, and mix the wetted activated carbon with 200 grams of chitosan in a blender, then weigh 50 grams of animal oil and moisten 1000 grams of polymer base polyethylene particles. Wet, and added to the blender and stirred with the aforementioned mixture, and then moved the blended mixture into the mixing hopper of the injection molding machine, and extruded through the filler mold to obtain 700 rigid polymer skeletons 1 . The rigid polymer framework 1 is a three-dimensional multifaceted hollow spherical structure with a diameter of 25mm. Prepare 600 grams of polyether propylene glycol, 600 grams of organic isocyanate, 25 grams of dibutyltin, 25 grams of triethylamine, 100 grams of dichloromethane, 50 grams of silicon-carbon bond copolymer and 500 ml of water, mix with rigid polymer skeleton 1 and speed Under stirring, it is quickly added to the molding box, and the chain growth, foaming, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com