Hole injection layer of organic small molecular and electroluminescent device thereof

A technology of electroluminescent devices and hole injection layers, which is applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of high requirements for equipment and environment, low yield, and difficult to control the doping ratio accurately. Achieve low requirements for equipment and environment, meet commercial use, and achieve the effect of large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

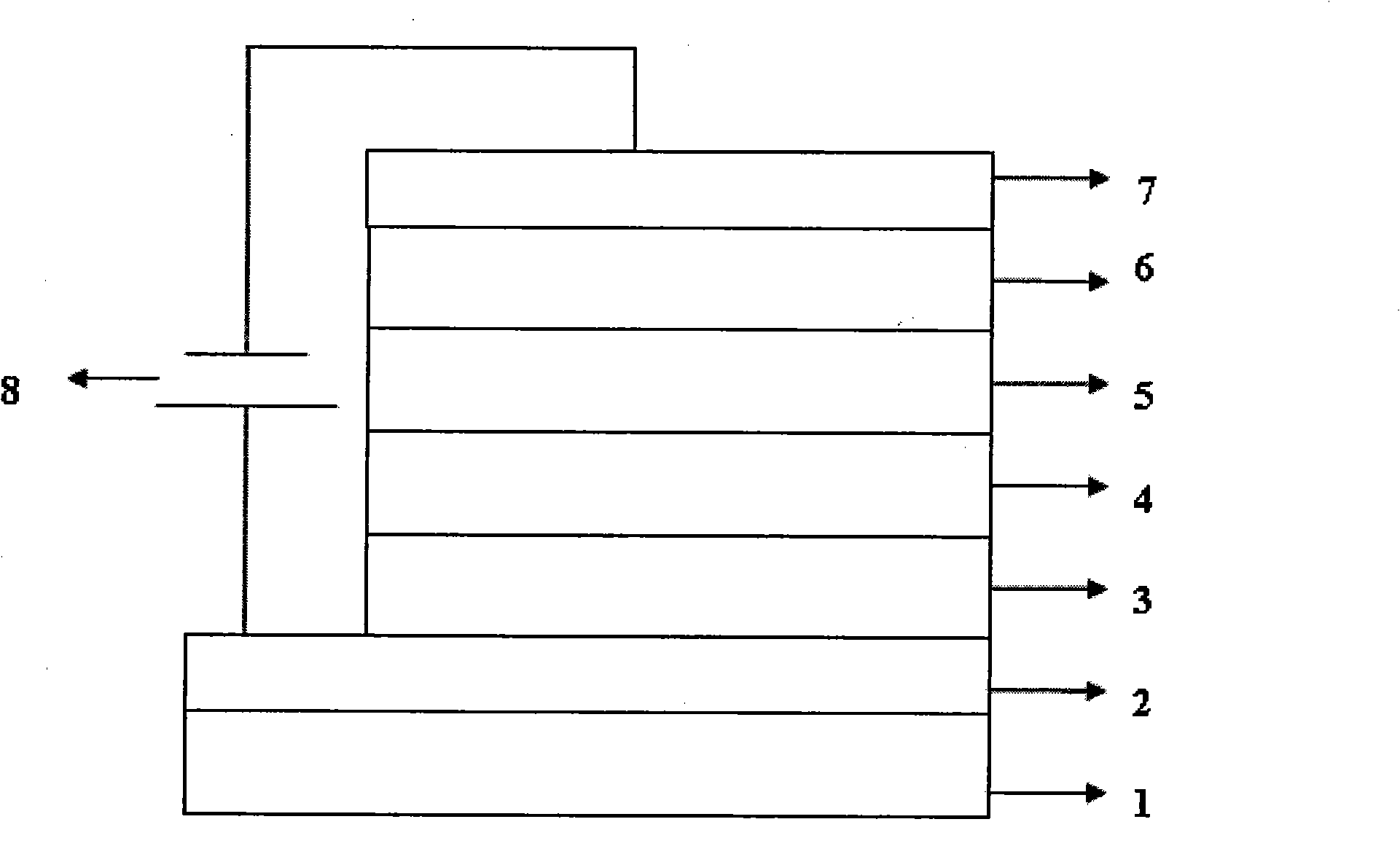

[0036] (3) Preparation of each organic functional layer: put the spin-coated and dried substrate 1 into a vacuum chamber, and then vapor-deposit a layer of hole-transporting material to form a hole-transporting layer 4. The transport materials are diamine compounds and triphenylamine compounds, preferably NPB or TPD, the evaporation rate of the material film is 0.01-0.5nm / s, and the film thickness is 10-80nm; a layer of The organic light-emitting material forms the organic light-emitting layer 5, and the organic light-emitting material is a material among metal-organic complexes, aromatic fused ring compounds, o-phenanthroline compounds or carbazole derivatives, and various fluorescent dyes and phosphorescent doped materials. Miscellaneous light-emitting layer, the evaporation rate of the material film is 0.01-0.5nm / s, and the film thickness is 20-80nm; a layer of electron transport material is evaporated on the organic light-emitting material to form the electron transport lay...

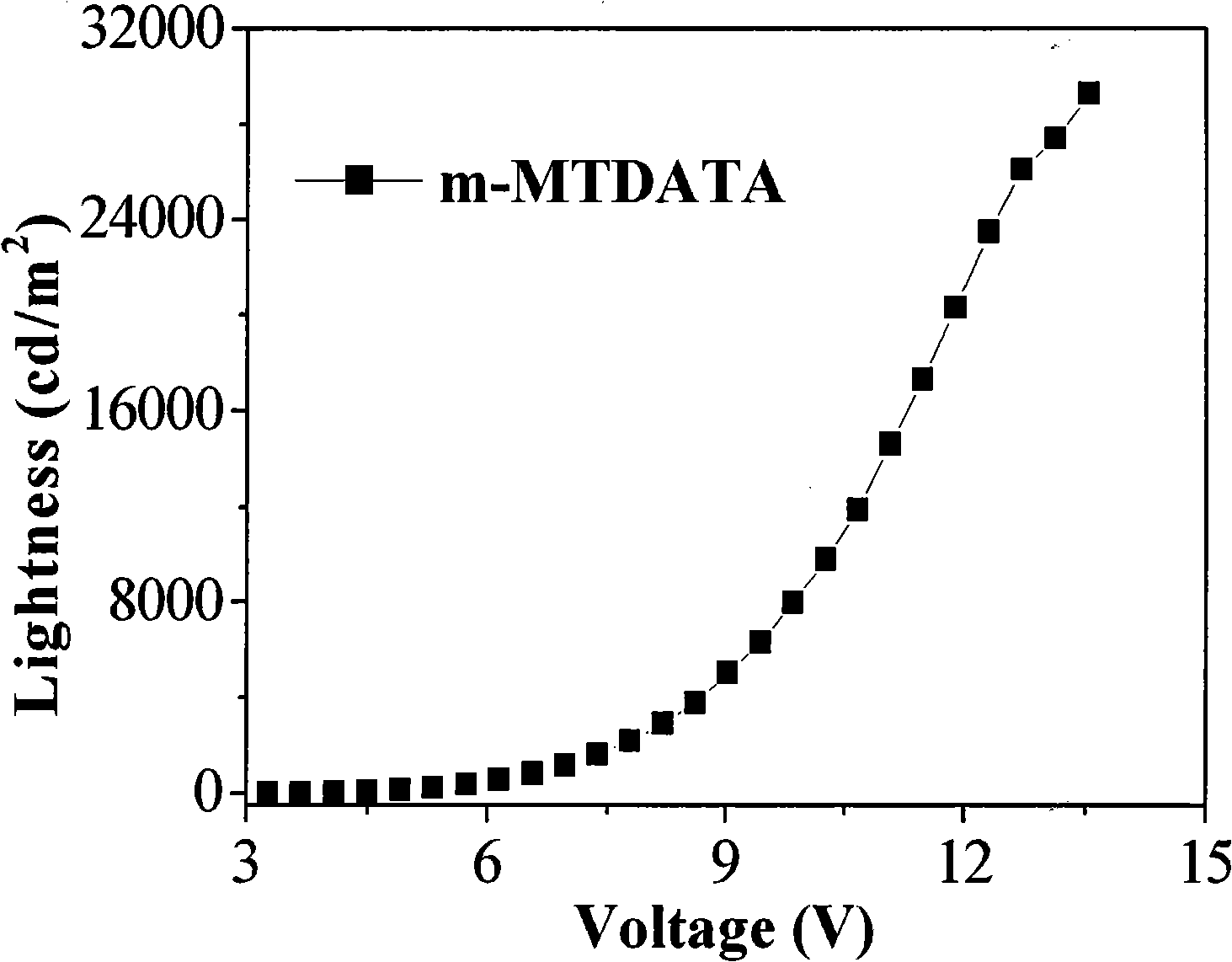

Embodiment 1

[0039] now refer to figure 1 , the electroluminescent device according to the first embodiment of the present invention has the following structure:

[0040] Glass (plastic) substrate / ITO(100nm) / m-MTDATA(50nm) / NPB(10nm) / Alq 3 (60nm) / LiF(0.5nm) / Al(80nm)

[0041] (1) Cleaning of glass substrates pre-engraved with ITO: use hot detergent ultrasonic and deionized water ultrasonic methods to clean the transparent conductive substrate ITO glass, and place it under an infrared lamp to dry after cleaning. The ITO film on the substrate is used as the anode layer of the device. The square resistance of the ITO film is 5Ω-100Ω, and the film thickness is 80-280nm. Figure 8 (a) is the surface topography map of ITOAFM;

[0042] (2) Organic small molecule hole injection layer: put the above-mentioned cleaned and dried ITO glass on the KW-4A homogenizer, and spin-coat the prepared 15mg / ml m-MTDATA chlorobenzene solution by static batching method to form For the film, the speed of the homo...

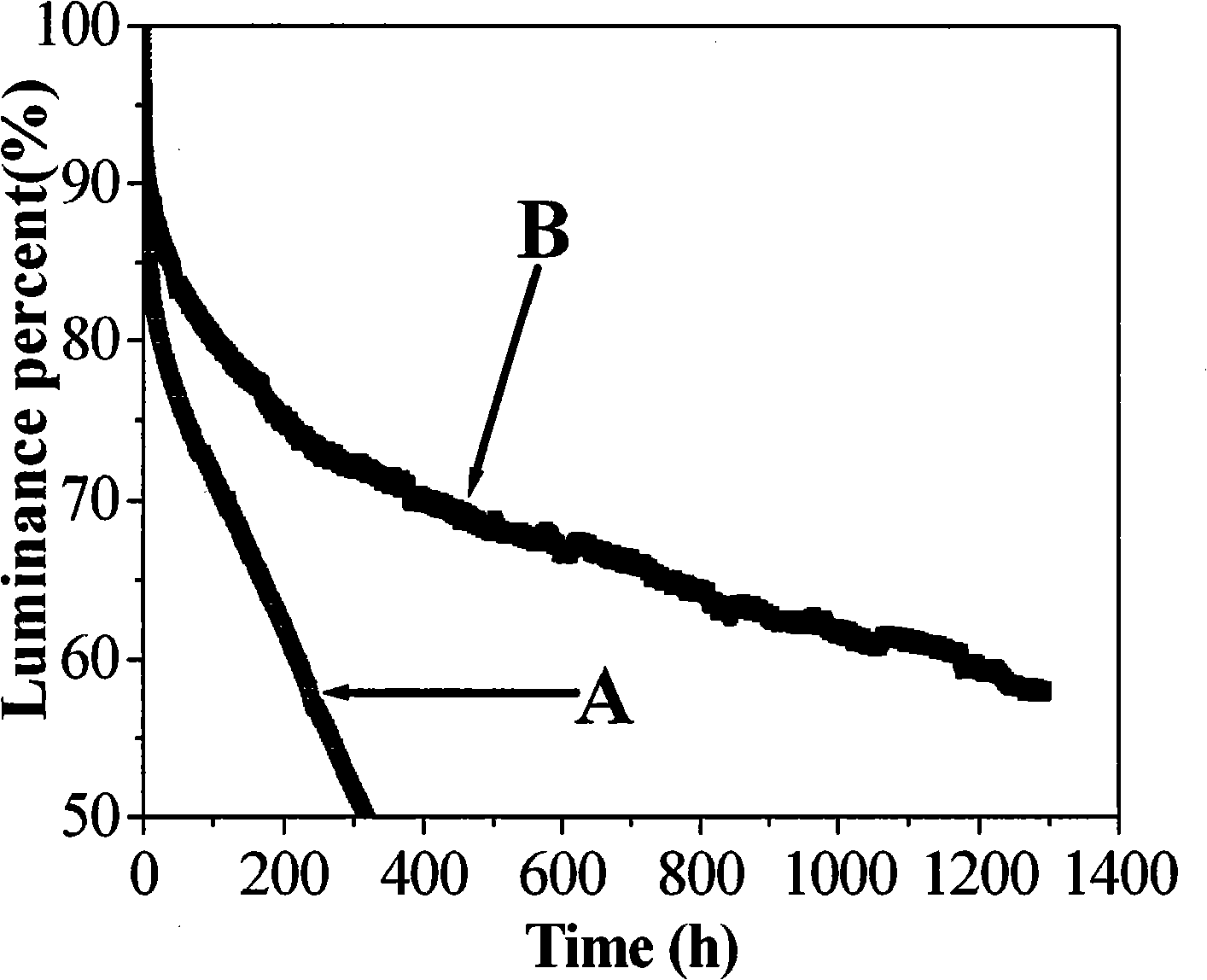

Embodiment 2

[0049] now refer to figure 1 , the electroluminescent device according to the second embodiment of the present invention has the following structure:

[0050] Glass (plastic) substrate / ITO(100nm) / NPB: m-MTDATA(50nm) / NPB(10nm) / Alq 3 (60nm) / LiF(0.5nm) / Al(80nm)

[0051] (1) The cleaning of the glass substrate that is engraved with ITO in advance: refer to the corresponding process of embodiment 1;

[0052] (2) Mixed organic small molecule hole injection layer: the mass ratio of NPB to m-MTDATA is 1:3, the concentration of the mixed solution is controlled at 15mg / ml, the solvent is preferably chlorobenzene, and the spin coating and drying conditions refer to the corresponding process of Example 1 ; Figure 8 (d) is the AFM image of the surface topography of the spin-coated small organic molecule hole injection layer.

[0053] (3) Preparation of each organic functional layer: refer to the corresponding process of Example 1;

[0054] (4) Preparation of negative electrode: the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com