Nano-hydroxyapatite hydrosol, preparation and application in toothpaste

A nano-hydroxyapatite and hydrosol technology, which is applied in chemical instruments and methods, dentistry, phosphorus compounds, etc., can solve the problems of increasing product cost, complex preparation and dispersion technology, and achieve reduced feeding time, easy process control, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The first step, the preparation calcium hydroxide content is 10kg of milk of lime of 15wt%, packs in the 25L reactor;

[0027] Second step, in described milk of lime, add 0.3kg glacial acetic acid, stir, obtain mixture;

[0028] The third step is to heat the mixture to 95°C, then gradually add 6kg of dilute phosphoric acid with a phosphoric acid content of 17wt% and continue to stir, the stirring speed is 600r / min, the time for adding dilute phosphoric acid is 3min, continue to react for 6 hours, and finally use 2wt% acetic acid solution adjusted the pH value to 8.0, cooled naturally to obtain nano-hydroxyapatite hydrosol.

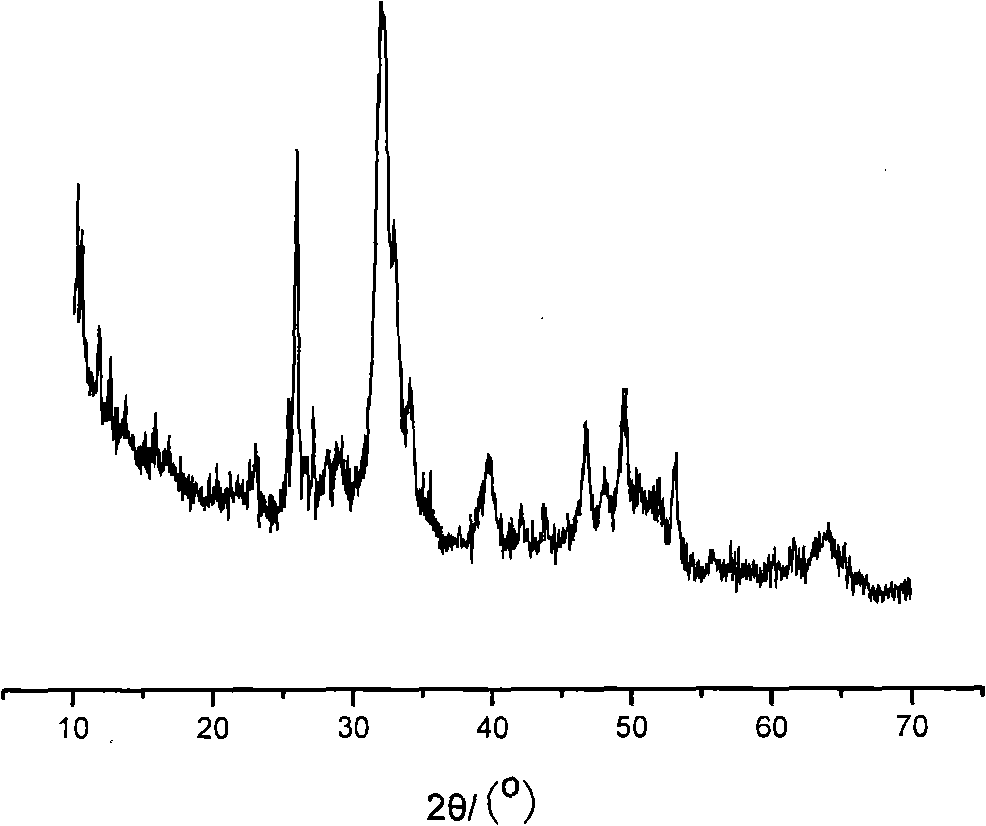

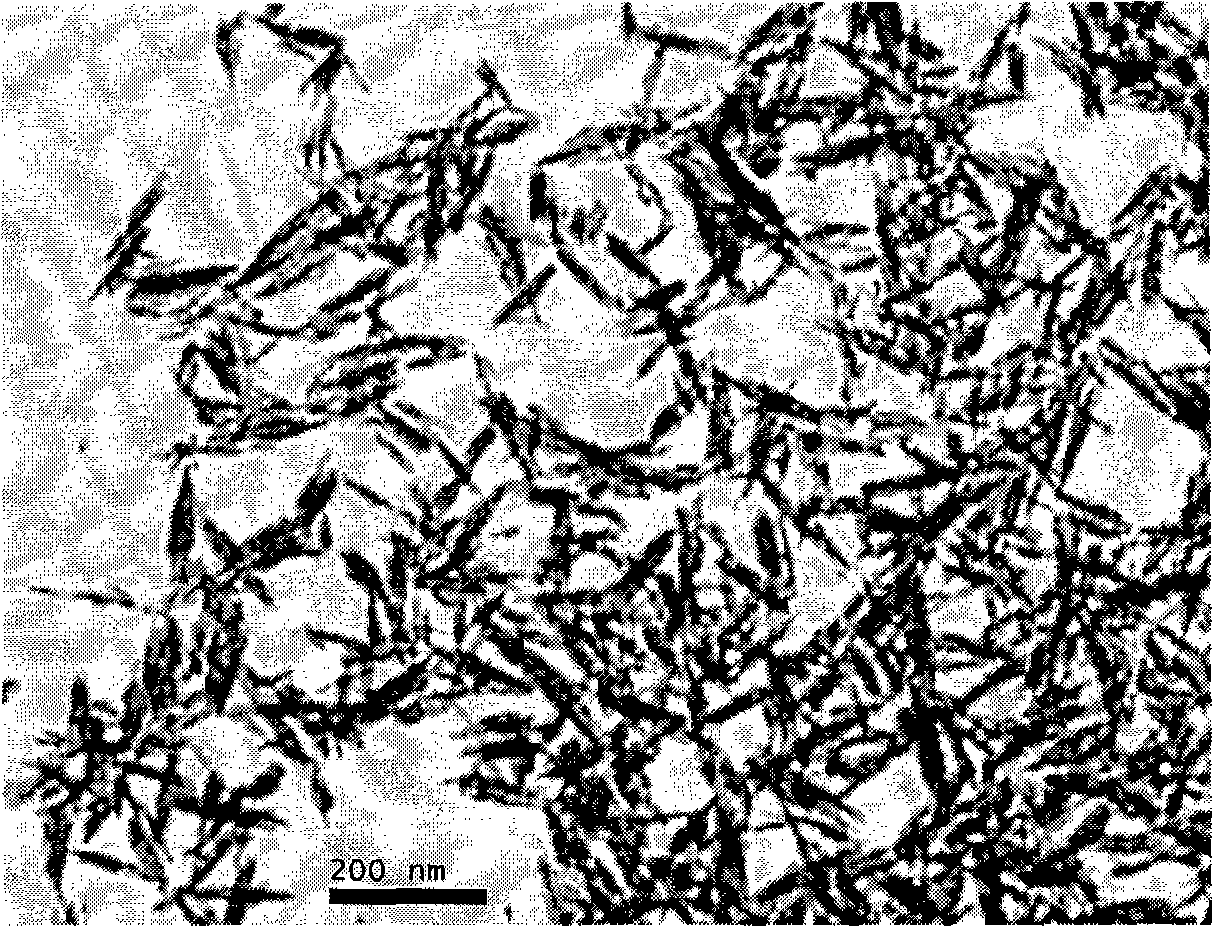

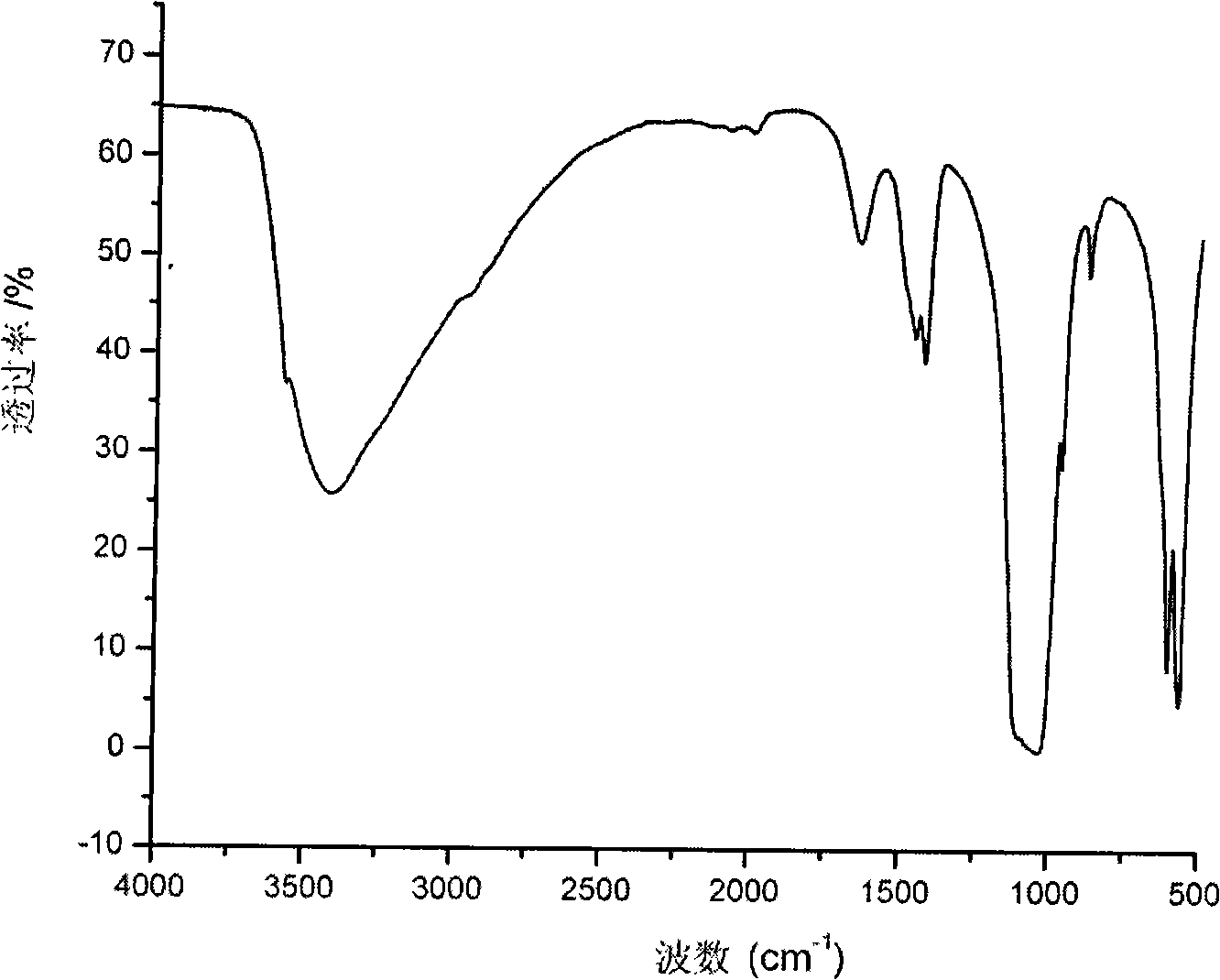

[0029] The XRD pattern of the solid matter in the prepared nano-hydroxyapatite hydrosol is as follows figure 1 As can be seen from the characteristics shown in its XRD figure, the solid matter in the colloid is low crystallinity hydroxyapatite; the TEM figure of the nano-hydroxyapatite hydrosol is as follows figure 2 shown, from figure 2 It can...

Embodiment 2

[0037] The first step, the preparation calcium hydroxide content is 10kg of milk of lime of 18wt%, packs in the 25L reactor;

[0038] In the second step, 0.6kg calcium acetate is added in the milk of lime, and stirred evenly to obtain a mixture;

[0039] In the third step, the mixture is heated to 65° C., then gradually add 7.1 kg of dilute phosphoric acid with a phosphoric acid content of 20 wt % and continue to stir at a stirring speed of 800 r / min. The time for adding dilute phosphoric acid is 5 minutes, and the reaction is continued for 8 hours. Adjust the pH value to 8.0 with 2wt% acetic acid solution, and cool naturally to obtain nano-hydroxyapatite hydrosol.

[0040] The prepared nano-hydroxyapatite hydrosol is used to prepare toothpaste, except for the nano-hydroxyapatite hydrosol, the raw materials used in the preparation of toothpaste in the prior art are used in the raw materials for preparing the toothpaste, and the preparation process also adopts the prior art . ...

Embodiment 3

[0047] The first step, the preparation calcium hydroxide content is 10kg of milk of lime of 22wt%, packs in 25L reactor;

[0048] In the second step, 0.8kg calcium acetate is added in the milk of lime, and stirred evenly to obtain a mixture;

[0049] The third step is to heat the mixture to 90°C, then gradually add 5.7kg of dilute phosphoric acid with a phosphoric acid content of 30wt% and continue to stir, the stirring speed is 600r / min, the time for adding dilute phosphoric acid is 10min, continue to react for 12 hours, and finally Adjust the pH value to 8.0 with 2wt% acetic acid solution, and cool naturally to obtain nano-hydroxyapatite hydrosol.

[0050] The prepared nano-hydroxyapatite hydrosol is used to prepare toothpaste, except for the nano-hydroxyapatite hydrosol, the raw materials used in the preparation of toothpaste in the prior art are used in the raw materials for preparing the toothpaste, and the preparation process also adopts the prior art .

[0051] The ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com