Method for separating and recycling chloromethane with chloromethane mixture gas

A technology for separation and recovery of mixed gases, applied in chemical instruments and methods, preparation of halogenated hydrocarbons, organic chemistry, etc., can solve problems that do not have industrialization conditions, are difficult to desorb, and are short, usually a few seconds to a few minutes. , to achieve good economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

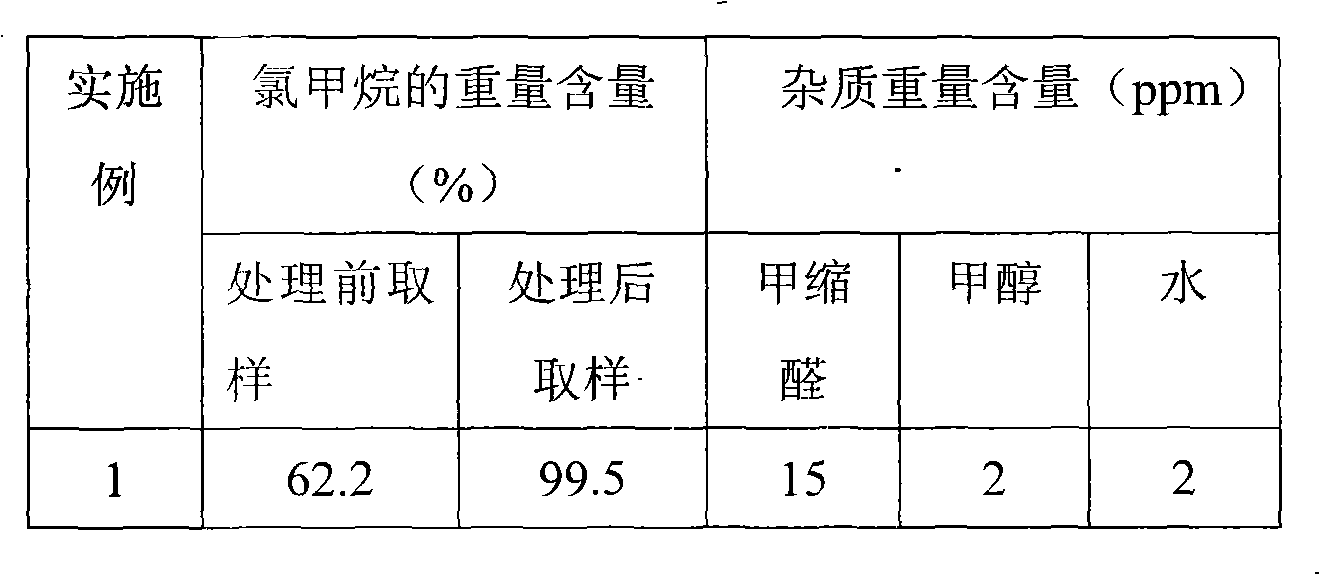

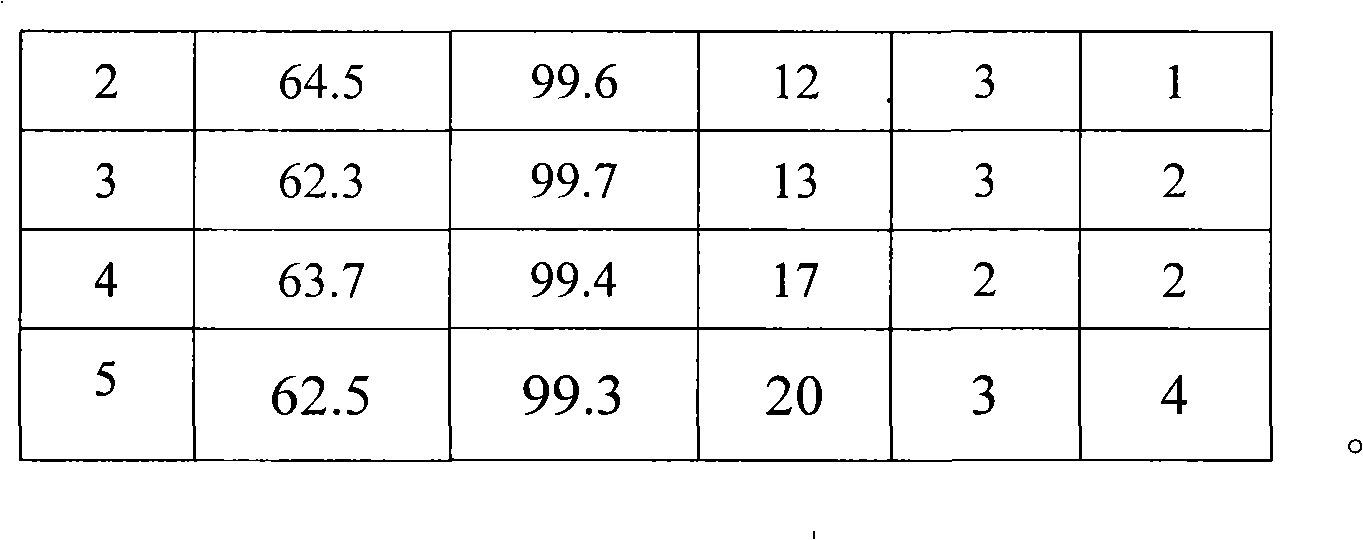

Examples

Embodiment 1

[0037] After absorbing hydrogen chloride with 15%-30% sodium hydroxide lye, the mixed gas of chloromethane enters the inlet of the compressor through the buffer tank, pressurizes to a gauge pressure of 0.5MPa, cools to 5°C, and condenses to separate part of methanol and methylal After being mixed with water and other impurities, it enters a temperature swing adsorption system with two towers connected in series and two towers connected in parallel under normal pressure for temperature swing adsorption separation treatment, and the non-adsorbed methyl chloride gas is obtained from the outlet of the adsorption tower. One group of towers in the adsorption system operates at room temperature, and the other group of towers is regenerated with nitrogen purging at 150°C for recycling. The conversion of the adsorption tower device is automatically operated by computer control. The adsorbents loaded in the same way in the two groups of adsorption towers are color-changing silica gel an...

Embodiment 2

[0039] Carry out separation operation in the mode of embodiment 1, select activated carbon and 4A molecular sieve as adsorbent, the loading volume ratio is 1: 2.

Embodiment 3

[0041] The separation operation was carried out in the manner of Example 1, and the adsorbent was selected from color-changing silica gel and 5A molecular sieve, and the filling volume ratio was 1:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com