Method for preparing organic metal compound anti-cancer medicine with electrostatic spinning technique

An electrospinning technology and organometallic technology, applied in the field of nano-biomedicine and materials, can solve the problems of severe nephrotoxicity, nausea and vomiting, cisplatin restriction, etc., and achieve low production cost, simple preparation process, and large single-time output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

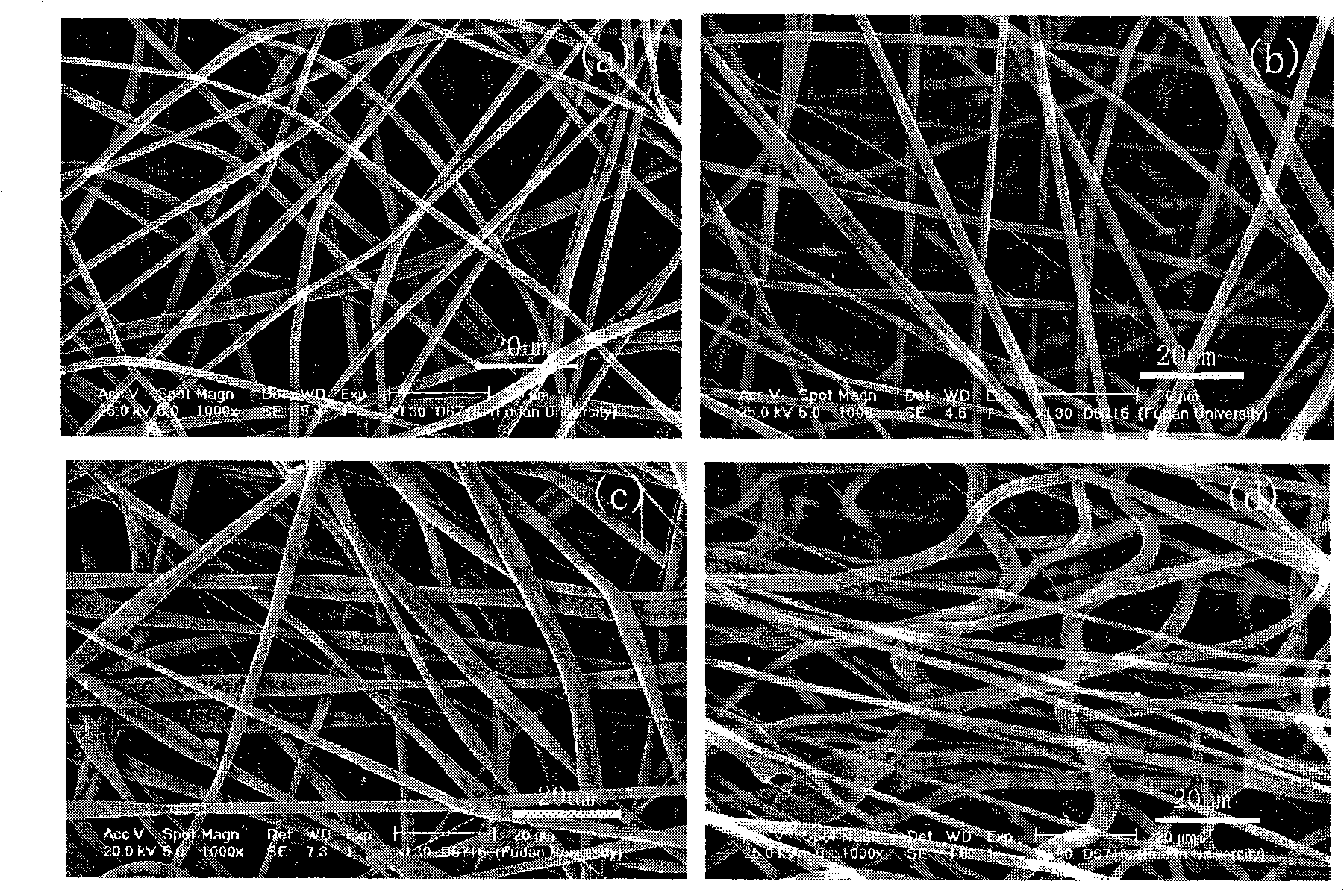

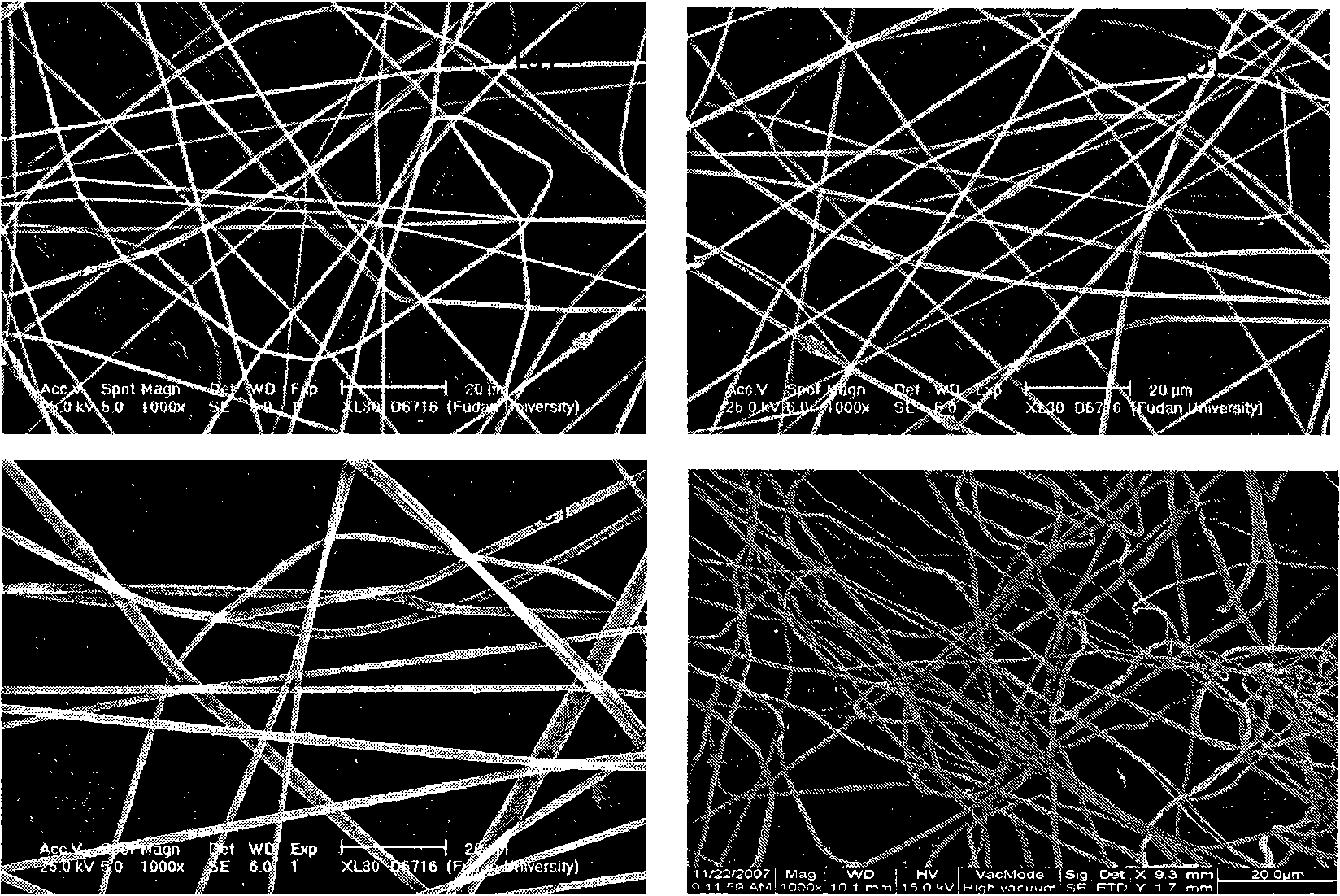

[0030] 1) Accurately measure PLLA (the mass ratio of PLLA in dichloromethane solvent is 5wt%) solute and dichloromethane solvent with an analytical balance, place in a clean glass dish and stir for about 2 hours under the action of a magnetic stirrer until completely dissolved , to obtain solution A. Accurately measure titanocene dichloride (the mass ratio of titanocene dichloride is 0.4wt%) solute and dichloromethane solvent with an analytical balance, place in a clean glass dish and stir for 2.5 hours under the action of a magnetic stirrer until completely dissolved , to obtain solution B.

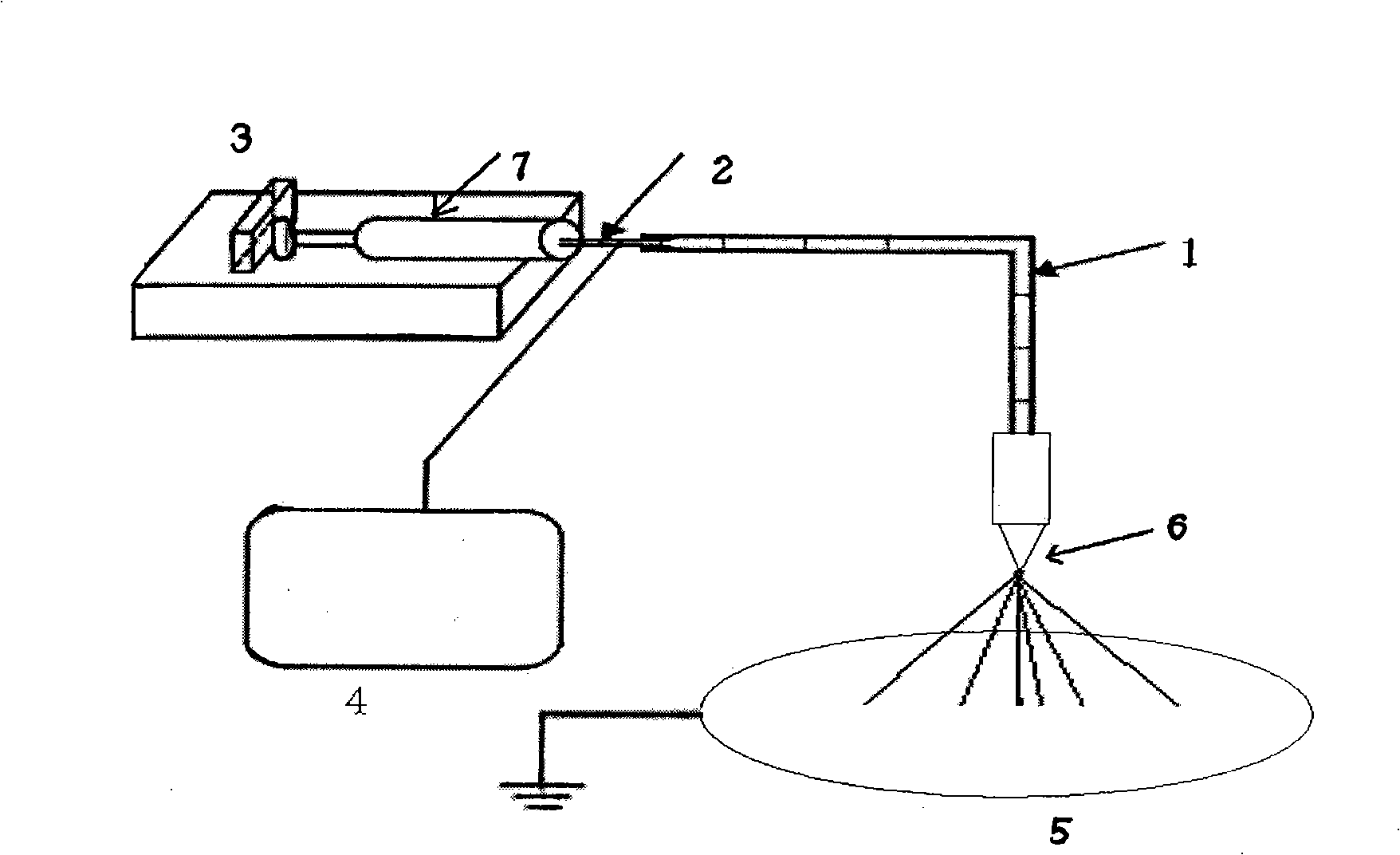

[0031] 2) Mix solution A and solution B evenly and add to the liquid storage tube, and spray it out from the spray needle under the condition of voltage applied by the high-voltage electrostatic generator. The controlled environment temperature is 18-20°C; the ambient humidity is 45%-50%; the distance between the collecting screens is 14-15 cm. The voltage is 14.0KV; the mass flow rate...

Embodiment 2

[0034] 1) Accurately measure PLLA (the mass ratio of PLLA is 5wt%) and dichloromethane solvent with an analytical balance, place in a clean glass dish and stir for about 2 hours under the action of a magnetic stirrer until completely dissolved to obtain solution A. Accurately measure titanocene dichloride (the mass ratio of titanocene dichloride is 0.6wt%) solute and dichloromethane solvent with an analytical balance, place in a clean glass dish and stir for about 2 hours under the action of a magnetic stirrer until completely dissolved , to obtain solution B.

[0035]2) Mix solution A and solution B evenly and add to the liquid storage tube, and spray it out from the spray needle under the condition of voltage applied by the high-voltage electrostatic generator. The controlled environment temperature is 18-20°C; the ambient humidity is 45%-50%; the distance between the collecting screens is 14-15 cm. The voltage is 16.0KV; the mass flow rate of the syringe pump is 6.0mL / h; t...

Embodiment 3

[0038] 1) Accurately measure PLLA (the mass ratio of PLLA is 5wt%) and dichloromethane solvent with an analytical balance, place in a clean glass dish and stir for about 2 hours under the action of a magnetic stirrer until completely dissolved to obtain solution A. Accurately measure titanocene dichloride (the mass ratio of titanocene dichloride is 0.8wt%) solute and dichloromethane solvent with an analytical balance, place in a clean glass dish and stir for about 2 hours under the action of a magnetic stirrer until completely dissolved , to obtain solution B.

[0039] 2) Solution A and solution B are mixed and sprayed out from the spray needle. The controlled environment temperature is 18-20°C; the ambient humidity is 45%-50%; the distance between the collecting screens is 14-15 cm. The voltage is 16.0KV; the mass flow rate of the syringe pump is 6.0mL / h; the product fibers are collected at the collection screen. The obtained product is micron-sized, with a size range of 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com