Catalyst for synthesizing pyridine using microsphere type high-silicon ZSM-5 molecular sieve as carrier and preparation method thereof

A technology of ZSM-5 and molecular sieve, which is applied in the field of pyridine synthesis catalyst and its preparation, can solve the problems of low catalyst yield and many by-products, and achieve the effect of avoiding the influence of binder and good activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

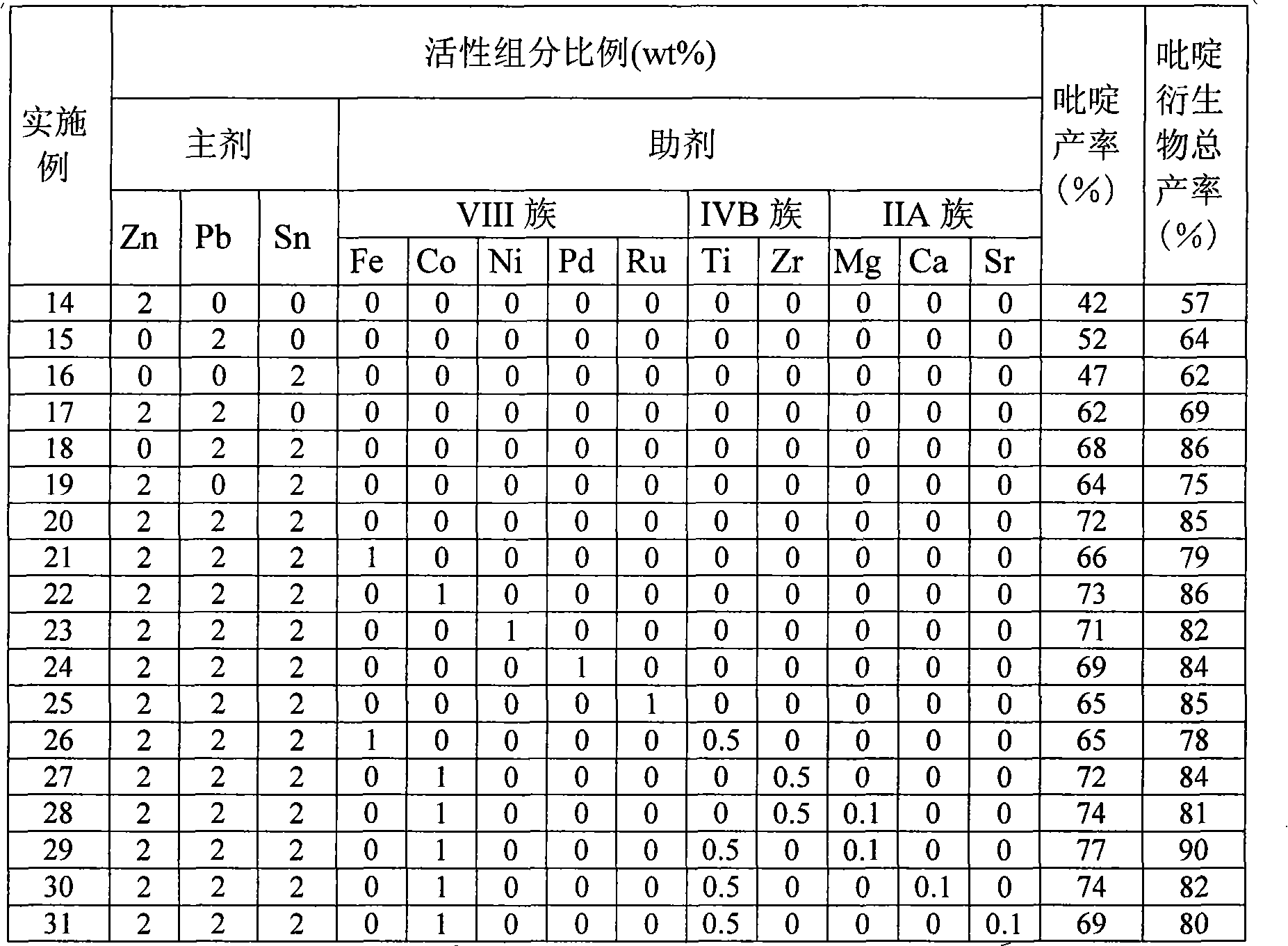

Examples

Embodiment 1~9

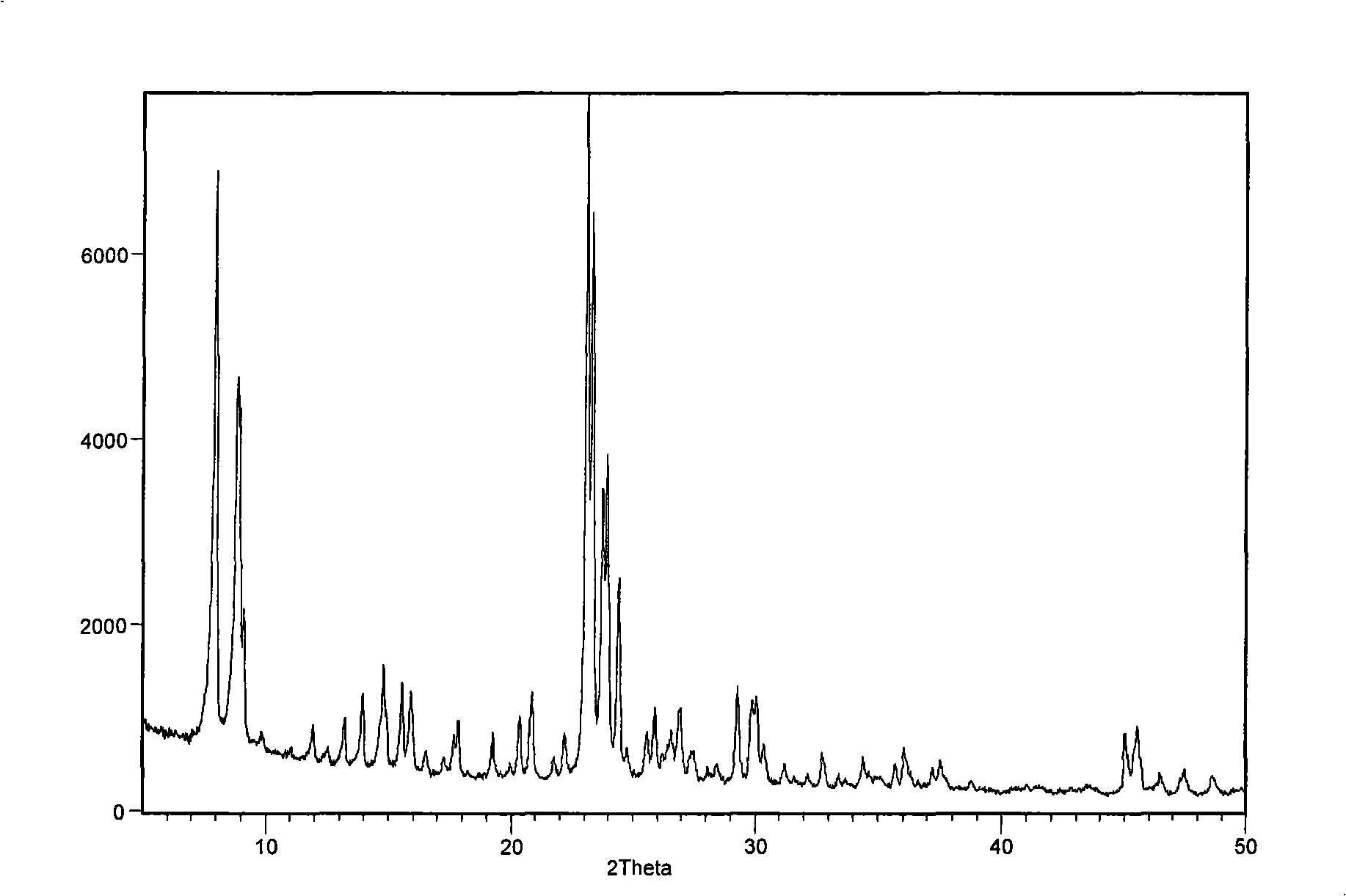

[0041] Embodiment 1~9: the synthesis of microsphere type high silicon ZSM-5 molecular sieve

Embodiment 1

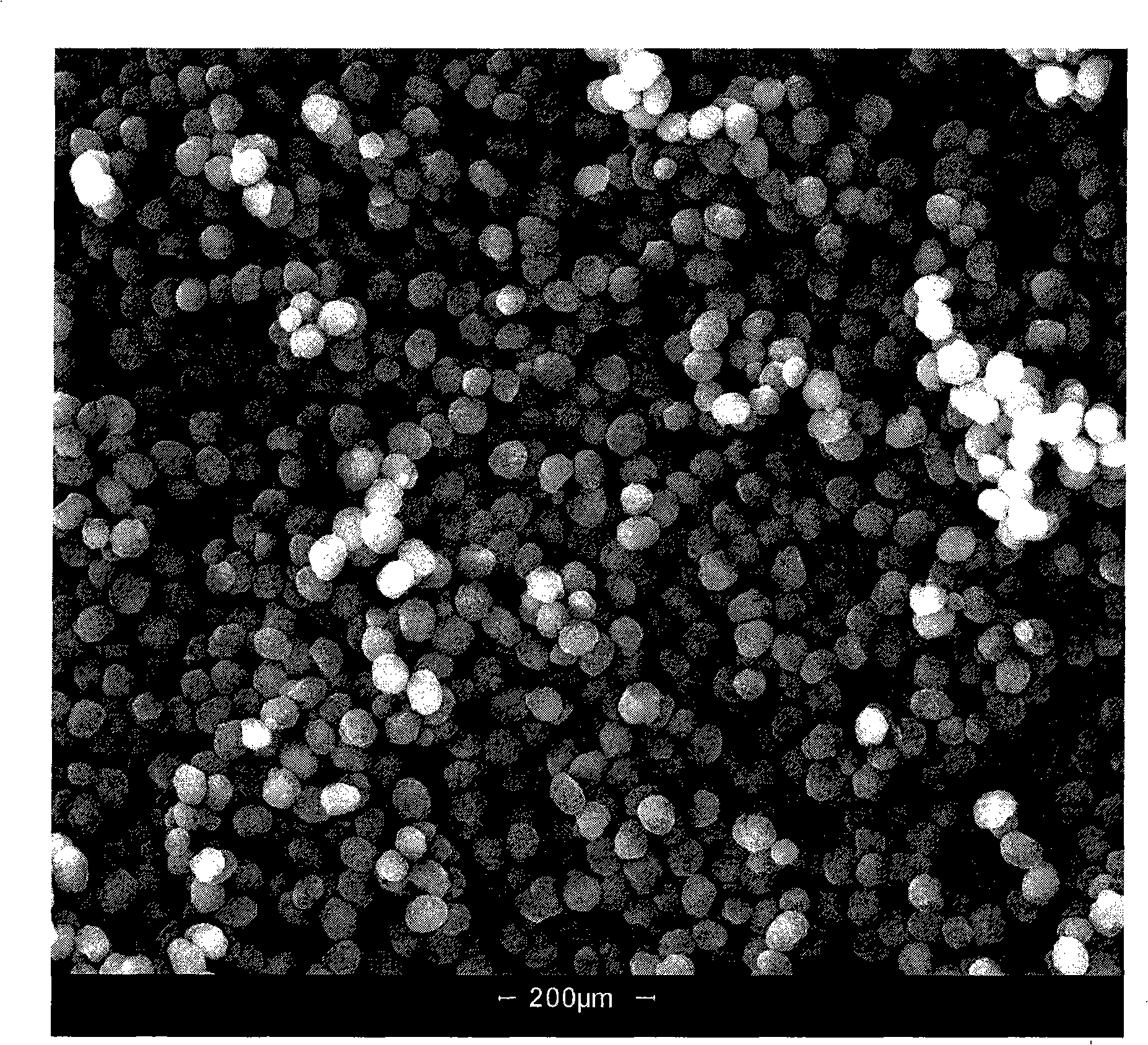

[0043] 1), preparation of silica-alumina microspheres

[0044] Add 0.023Kg potassium hydroxide and 0.84Kg 40% concentration of tetrapropyl ammonium hydroxide solution in 3.2Kg water, stir and dissolve, add 1.66Kg 30% concentration of silica sol, and then dissolve 0.018Kg aluminum sulfate into 0.36Kg water Make a solution, add this solution dropwise to the aforementioned silicon-containing solution, prepare a reaction mixture solution, hydrolyze it into a gel at room temperature, and obtain a uniform slurry, molar ratio SiO 2 :Al 2 o 3 : R: Potassium Hydroxide: H 2 O is 1:0.00333:0.2:0.05:35, wherein R is tetrapropylammonium hydroxide. The prepared slurry was spray-dried to obtain silica-alumina microspheres with a diameter of 60 microns.

[0045] 2), hydrothermal crystallization

[0046] Place the silica-alumina microspheres obtained in the first step in a bracket and place them in a hydrothermal device, add n-butylamine and water to the lower part, and the amount added i...

Embodiment 2

[0048] 1), preparation of silica-alumina microspheres

[0049] Add 0.17Kg sodium hydroxide and 0.042Kg 40% concentration of tetrapropylammonium hydroxide solution in 2.2Kg water, stir and dissolve, add 1.66Kg 30% concentration of silica sol, and then dissolve 0.0011Kg aluminum sulfate into 0.36Kg water Make a solution, add this solution dropwise to the aforementioned silicon-containing solution, prepare a reaction mixture solution, hydrolyze it into a gel at room temperature, and obtain a uniform slurry, molar ratio SiO 2 :Al 2 o 3 :R:NaOH:H 2 O is 1:0.0002:0.01:0.5:25, wherein R is tetrapropylammonium hydroxide. The prepared slurry was spray-dried to obtain silica-alumina microspheres with a diameter of 95 microns.

[0050] 2), hydrothermal crystallization

[0051] Place the silicon-aluminum microspheres obtained in the first step in a bracket and place them in a hydrothermal device, add monoethanolamine and water to the bottom, and the amount added is based on the molar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com