Solid-state fermentation method of mycophenolic acid

A solid-state fermentation, mycophenolic acid technology, applied in microorganism-based methods, fermentation, biochemical equipment and methods, etc., can solve problems such as affecting mass transfer and heat transfer efficiency, increasing system complexity, and easy to shrink and agglomerate. , to achieve the effect of being beneficial to mass and heat transfer, environmental protection and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

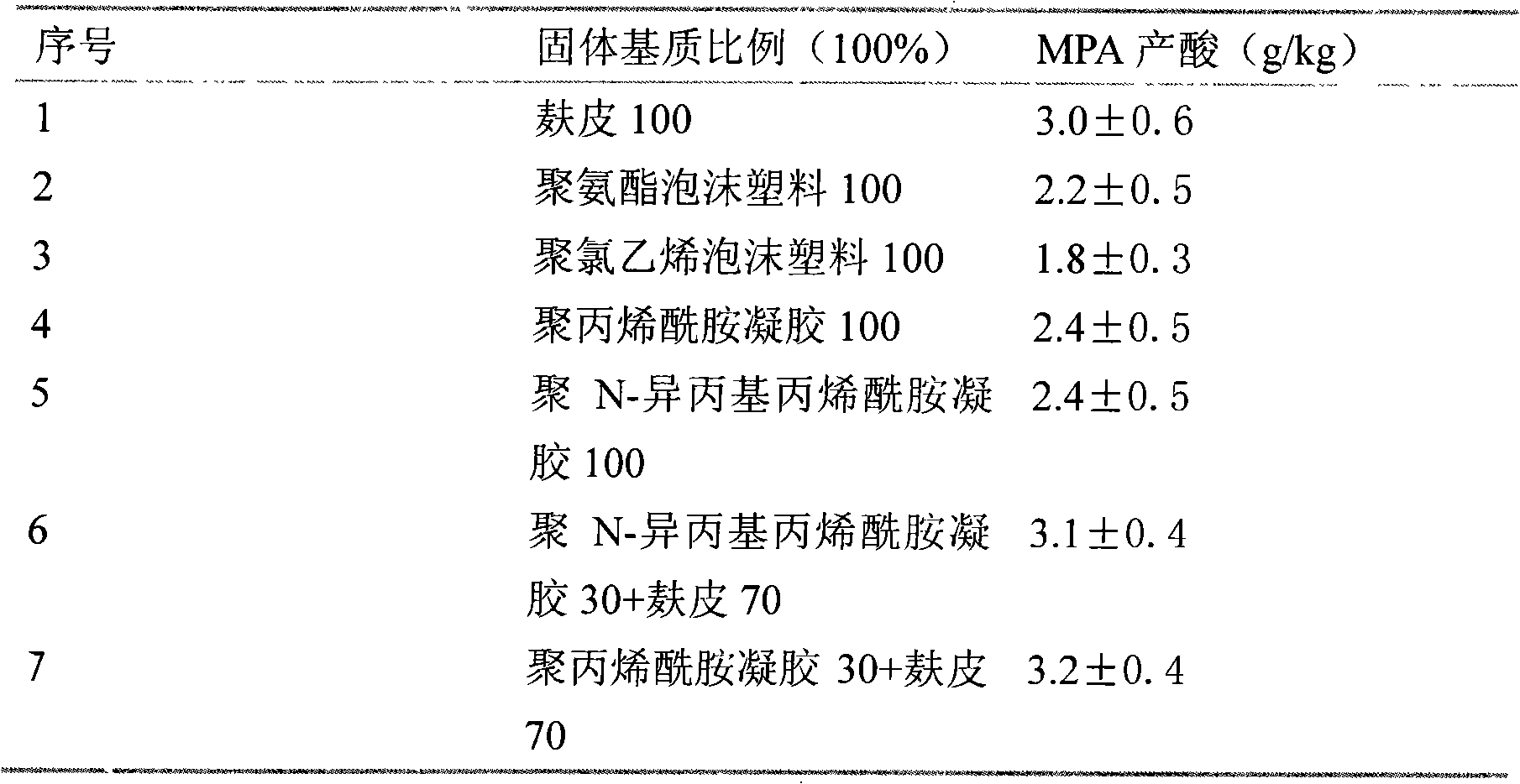

Examples

Embodiment 1

[0020] Cultivation of bacteria and seeds

[0021] The strain used is Penicillium brevicompactum P. brevicompactum, which is a single spore isolated from Penicillium brevicompactum, which is usually stored in potato dextrose agar (PDA) medium or spores are stored in glycerol tubes and stored in- 80°C refrigerator.

[0022] The strains were subcultured from fresh Potato Dextrose Agar (PDA) slant at a culture temperature of 28±1°C. After 8 days, the spores on the slant were washed with 10ml of normal saline containing 0.01% sterile Tween, and 5ml of bacterial suspension was taken. The solution is inserted into a 250ml shake flask, and 50ml of seed medium is installed inside, and the ingredients (g / L): 10 glucose, 5 corn steep liquor, 10 oat flour, 40 tomato paste, 10ml nutrient additive solution, and it consists of: FeSO 4 ·5H 2 O 1g, MnSO 4 ·7H 2 O 760mg, boric acid 56mg, CaCl 2 2H 2 O100mg, CuSO 4 ·5H 2 O 25mg, ammonium molybdate 19mg, ZnSO 4 ·5H 2 O 200mg, L-Asparagi...

Embodiment 2

[0024] Add 10g of bran into a 250ml shake flask, fill it with distilled water so that the initial cultivation humidity reaches 70%, then sterilize the shake flask at 121°C for 1h, wait for the shake flask to cool to 25°C, insert 5ml of the secondary seeds prepared in Example 1 The solution was fully mixed, and the shaker flask was placed in an environmental chamber for cultivation at a cultivation temperature of 25±1°C and a relative humidity (RH) of 80±5%, for 8 days and sampling once a day.

Embodiment 3

[0026] Add 7g of bran and 3g of polyurethane foam into a 250ml shake flask, fill with distilled water so that the initial cultivation humidity reaches 70%, then sterilize the shake flask at 121°C for 1h, wait for the shake flask to cool to 25°C, and insert 5ml of Example 1 The prepared secondary seed liquid was fully mixed, and the shake flask was placed into an environmental chamber for cultivation at a cultivation temperature of 25±1° C. and a relative humidity (RH) of 80±5%, and samples were taken once a day.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com