Multichannel high-efficient electrode with same variable electric field force

A multi-channel, electric field force technology, applied in the direction of electrostatic spraying device, chemical/physical/physicochemical process of energy application, spraying device, etc., can solve the problem of not being able to obtain electric field force at the outlet of the channel at the same time, and achieve easy high-temperature sterilization , uniform particle size, and the effect of reducing the encapsulation voltage value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

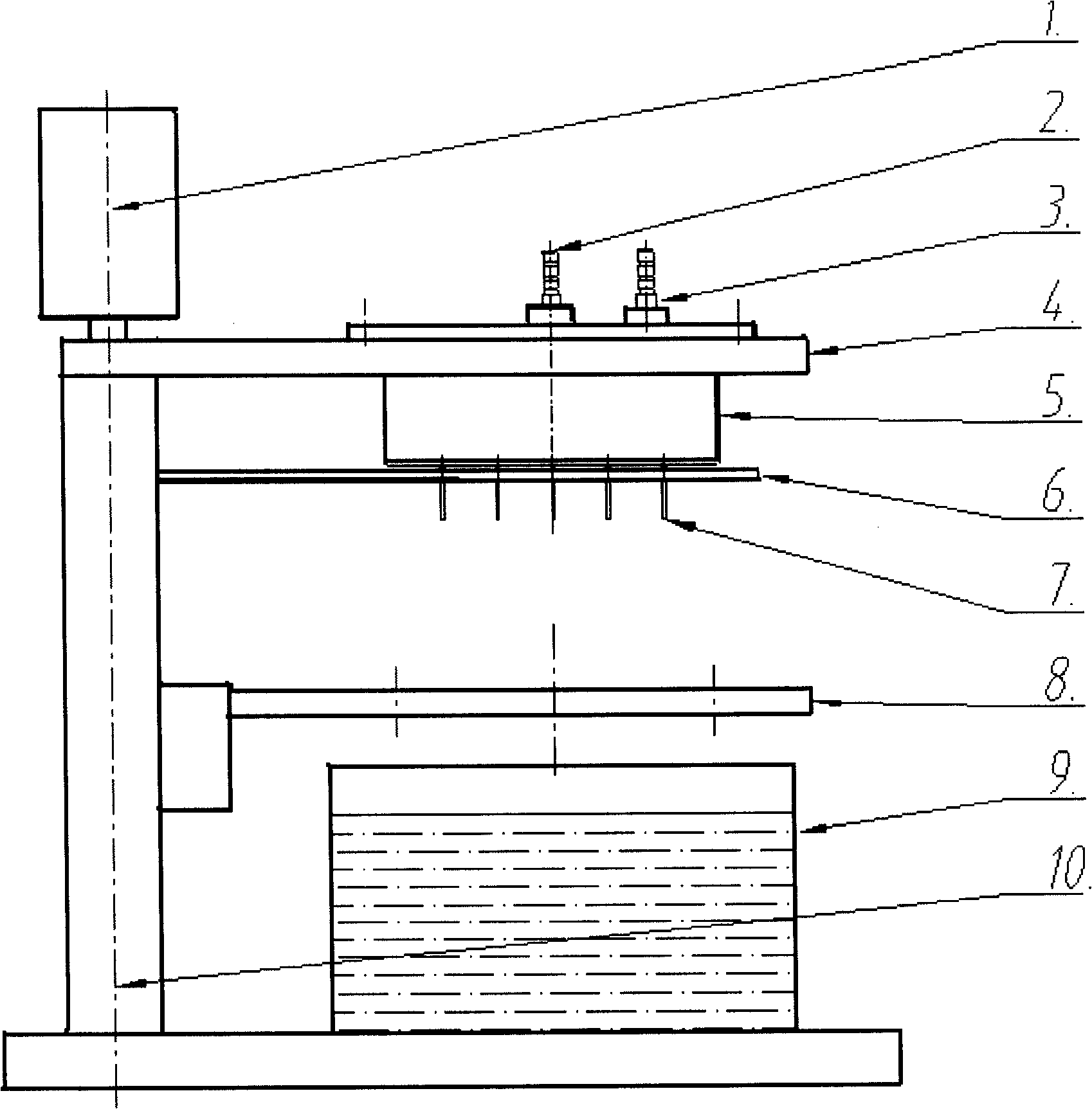

Method used

Image

Examples

Embodiment 1

[0045] 1. Sodium alginate is dispersed in 0.9% saline to form 1.5% (w / v) sodium alginate raw material solution; 1.11% (w / v) CaCl 2 The solution is a gel bath.

[0046] 2. In the case of high-voltage pulse voltage + Upp = 5.0kV, frequency f = 110Hz, pulse width 4ms, threshold voltage U = 1000V, the raw material solution of sodium alginate is 0.075MPa under the pressure of Φ0.4mm Flow out from the sharp hole of the channel, fall into the gel bath to solidify, and form calcium alginate microgel beads with a particle size of 750 μm, and the output is 2000ml / h.

[0047] 3. The prepared microgel beads were observed by the biological inverted microscope CK40 type of Japan Olympus Company (such as figure 2 ).

[0048] 4. Adopt the American Beckman-Coulter company LS-100Q type laser particle size analyzer to measure the particle size and particle size distribution of composite polymer microspheres (such as Figure 4 ).

[0049] 5. Measure the volume of microgel beads collected wit...

Embodiment 2

[0051] 1. Sodium alginate is dispersed in 0.9% saline to form 1.0% (w / v) sodium alginate raw material solution; 1.11% (w / v) CaCl 2 The solution is a gel bath.

[0052] 2. In the case of high-voltage pulse voltage Upp=6.8kV, frequency f=140Hz, pulse width 5ms, threshold voltage U=0V, the raw material solution of sodium alginate under the pressure of 0.085MPa, from nineteen Flow out from the sharp hole of the channel, fall into the gel bath to solidify, and form calcium alginate microgel beads with a particle size of 300 μm, with an output of 400ml / h.

[0053] 3. Same as embodiment 1, the results are shown in image 3 .

[0054] 4. Same as Example 1, the results are shown in Figure 5 .

[0055] 5. Same as embodiment 1.

Embodiment 3

[0057] In the existing literature, the buried electrode formed by the metal ring placed in the gel bath is used as the ground electrode, and the comparison experiment between the buried electrode and this electrode is carried out:

[0058] 1. Sodium alginate is dispersed in 0.9% saline to form 1.5% (w / v) sodium alginate raw material solution; 1.11% (w / v) CaCl 2 The solution is a gel bath.

[0059] 2. Parameter comparison:

[0060]

[0061] 3. The prepared microgel beads were observed by the CK40 biological inverted microscope of Japan Olympus Company, as shown in Figure 6 for details. When the electrode is used and the pulse voltage is reduced by 62%, the generated microcapsules have a better shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com