Method for preparing double-layer self peeling nano porous anodised aluminum film

A technology of anodized aluminum and porous anodes, applied in the field of material chemistry, can solve problems such as corrosion, poor effect of membrane through-holes, expensive equipment, etc., achieve regular pore diameters, and avoid the effects of chemical corrosion and pore expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

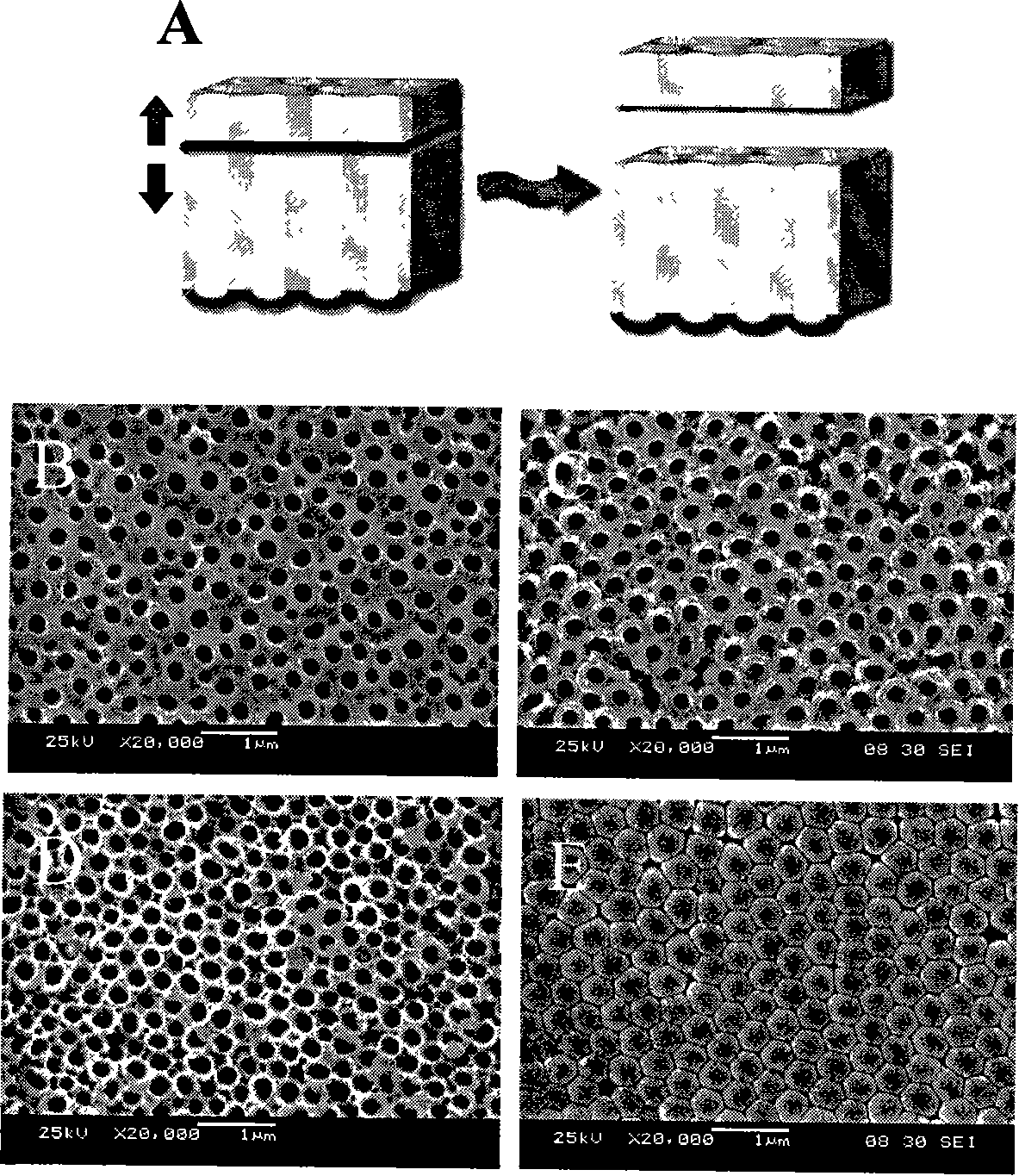

[0030] The steps of preparing double-layer self-stripping porous anodic aluminum oxide membrane provided by the invention are as follows:

[0031] (1) The aluminum sheet is annealed at 500° C. for 5 hours under the protection of nitrogen atmosphere. Electrochemical polishing was performed for 5 minutes in a 1:5 perchloric acid-ethanol mixture solution at a potential of 20V.

[0032] (2) install the aluminum sheet after the pretreatment of step (1) in the U-shaped electrolytic cell system as the anode, add the phosphoric acid that contains 1.0mol / L of 50% polyethylene glycol-400 as the electrolysis Liquid, with a clean large-area aluminum sheet as the cathode to form a two-electrode electrolysis system;

[0033] (3) Adopting a constant temperature water bath to control the temperature of the electrolytic cell to be 15°C;

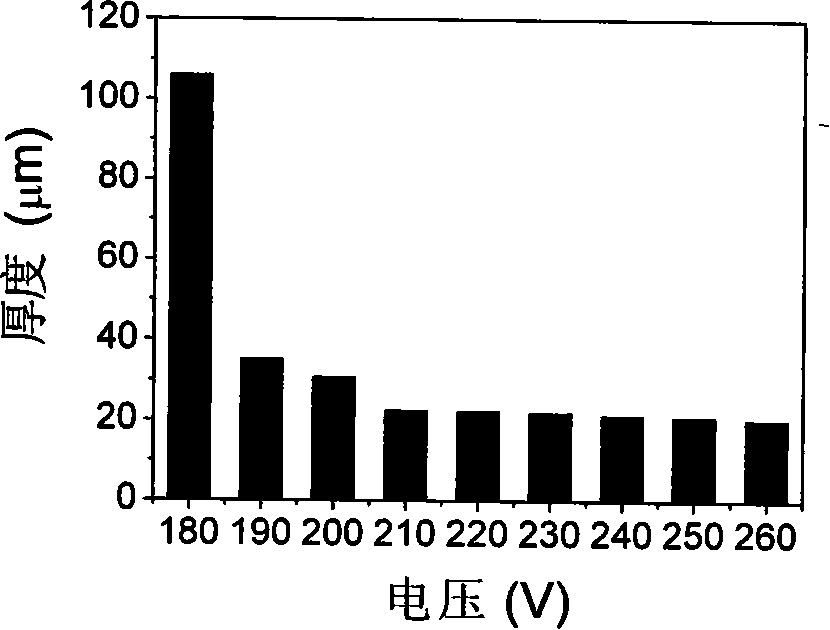

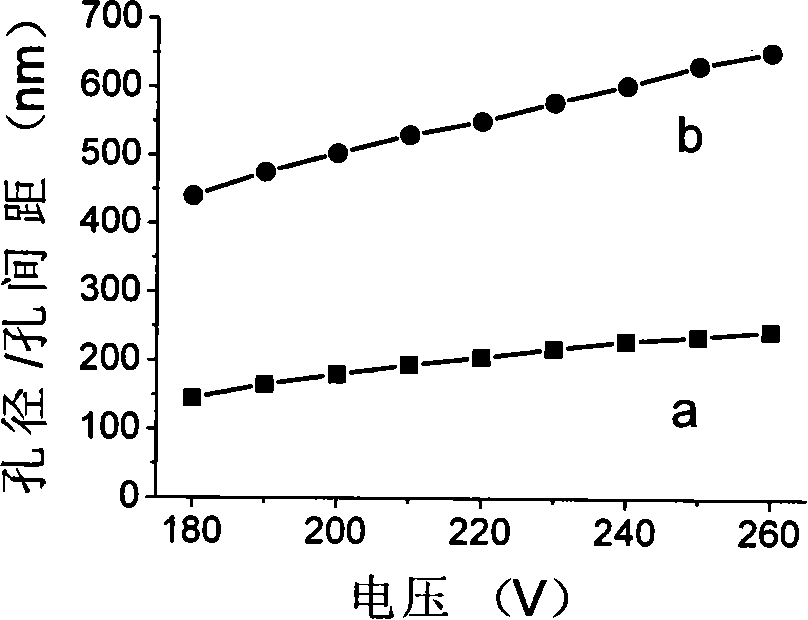

[0034] (4) Use a potentiostat to control the oxidation potential, and perform electrolysis at 180V, 190V, 200V, 210V, 220V, 230V, 240V, 250V and 260V;

[...

Embodiment 2

[0038] The steps of preparing double-layer self-stripping porous anodic aluminum oxide membrane provided by the invention are as follows:

[0039] (1) The aluminum sheet is annealed at 500° C. for 5 hours under the protection of nitrogen atmosphere. Electrochemical polishing was performed for 5 minutes in a 1:5 perchloric acid-ethanol mixture solution at a potential of 20V.

[0040] (2) install the aluminum sheet after the pretreatment of step (1) in the U-shaped electrolytic cell system as the anode, add the phosphoric acid that contains 1.0mol / L of 50% polyethylene glycol-400 as the electrolysis Liquid, with a clean large-area aluminum sheet as the cathode to form a two-electrode electrolysis system;

[0041] (3) Adopting a constant temperature water bath to control the temperature of the electrolytic cell to be 15°C;

[0042] (4) Adopt potentiostat to control oxidation potential, carry out electrolysis with 190V;

[0043] (5) Connect the power supply in step (4) to the a...

Embodiment 3

[0046] The steps of preparing double-layer self-stripping porous anodic aluminum oxide membrane provided by the invention are as follows:

[0047] (1) The aluminum sheet is annealed at 500° C. for 5 hours under the protection of nitrogen atmosphere. Electrochemical polishing was performed for 5 minutes in a 1:5 perchloric acid-ethanol mixture solution at a potential of 20V.

[0048] (2) install the aluminum sheet after the pretreatment of step (1) in the U-shaped electrolytic cell system as the anode, and add the concentration of 50% polyethylene glycol-400 containing 0.8mol / L, 1.0mol / L, 1.5mol / L and 2.0mol / L phosphoric acid are used as the electrolyte, and a clean large-area aluminum sheet is used as the cathode to form a two-electrode electrolysis system;

[0049] (3) Adopting a constant temperature water bath to control the temperature of the electrolytic cell to be 15°C;

[0050] (4) Adopt potentiostat to control oxidation potential, carry out electrolysis with 190V;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com