Artificial cardiac valve stitching ring polyester material with antibiosis function

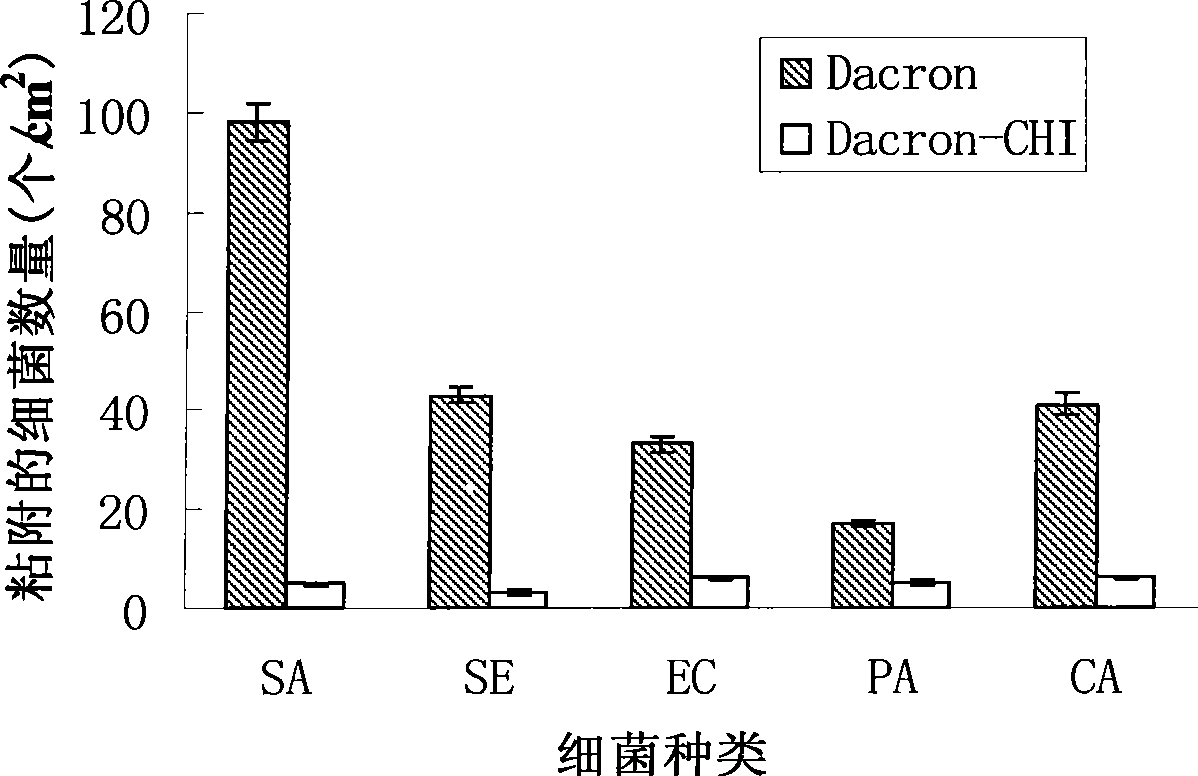

An artificial heart valve and sewing ring technology, applied in heart valve, medical science, fiber type, etc., can solve the problems of poor histocompatibility of silver coating, reduce the incidence of PVE, paravalvular leakage, etc., and achieve good histocompatibility effect of reducing infective endocarditis and overcoming paravalvular leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

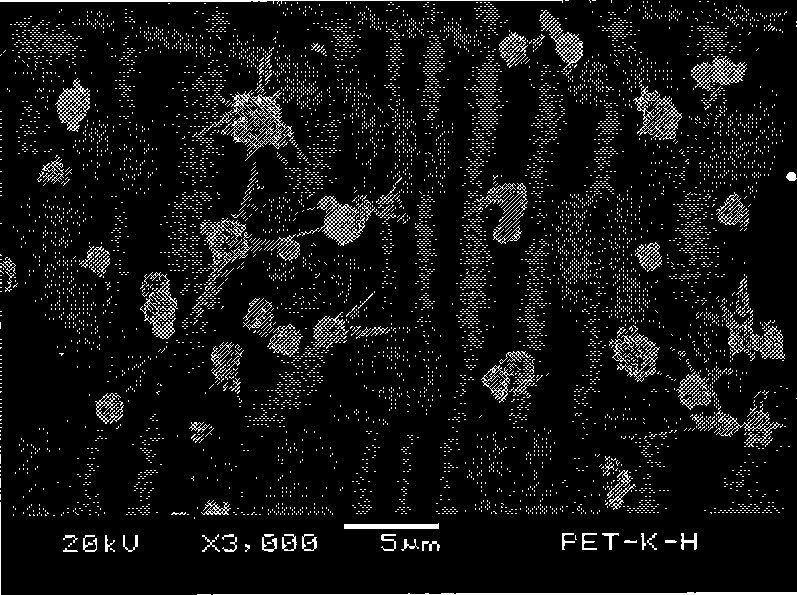

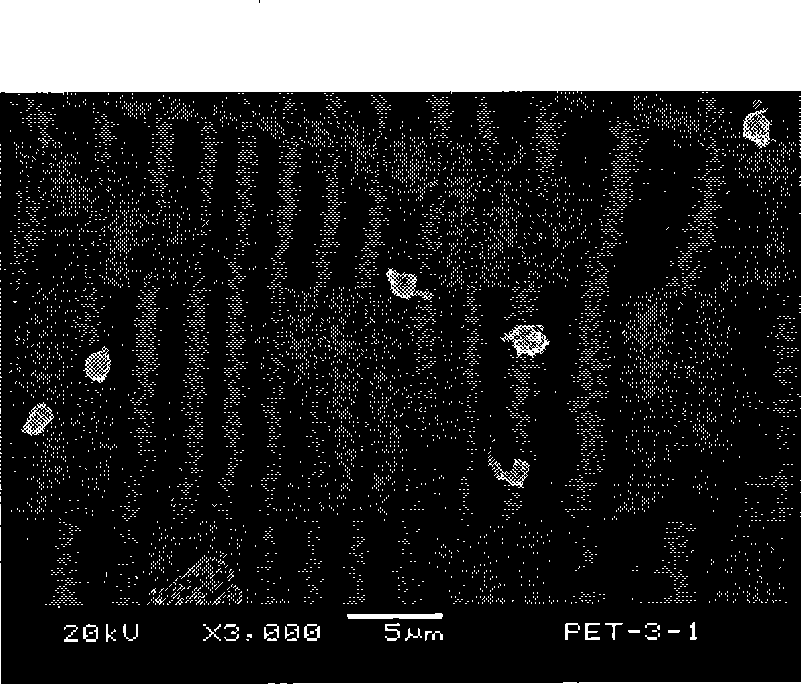

Image

Examples

Embodiment 1

[0023] The first specific embodiment of the present invention is a kind of artificial heart valve sewing ring polyester material with antibacterial function, which is made by the following method:

[0024] A, the Dacron non-woven polyester material that the artificial heart valve sewing ring is used will be prepared by every 400cm 2 The polyester material is subjected to 8ml / min, 30min ozone surface activation;

[0025] The polyester material after ozone activation was transferred to another reaction flask, and vacuum degassed for 30 minutes.

[0026] B. React the surface-activated polyester material with an aqueous solution of acrylic acid monomer to graft and copolymerize acrylic acid on the surface; the concentration of the aqueous solution of acrylic acid monomer is 5 wt%, the polymerization reaction temperature is 30° C., and the time is 60 minutes.

[0027] C, the terylene material that the surface graft copolymerization acrylic acid that B step obtains is immersed in t...

Embodiment 2

[0031] A kind of artificial heart valve sewing ring polyester material with antibacterial function is prepared by the following method:

[0032] A, the Dacron non-woven polyester material that the artificial heart valve sewing ring is used will be prepared by every 400cm 2 The polyester material is subjected to 12ml / min, 40min ozone surface activation;

[0033] The polyester material after ozone activation was transferred to another reaction bottle, and vacuum degassed for 60 minutes.

[0034] B. React the surface-activated polyester material with an aqueous solution of acrylic acid monomer to graft and copolymerize acrylic acid on the surface; the concentration of the aqueous solution of acrylic acid monomer is 10 wt%, the polymerization reaction temperature is 40° C., and the time is 120 minutes.

[0035] C, the terylene material that the surface graft copolymerization acrylic acid that B step obtains is immersed in the phosphate buffer solution of 1-(3-dimethylaminopropyl ...

Embodiment 3

[0040] A kind of artificial heart valve sewing ring polyester material with antibacterial function is prepared by the following method:

[0041] A, the Dacron non-woven polyester material that the artificial heart valve sewing ring is used will be prepared by every 400cm 2 The polyester material is subjected to 15ml / min, 50min ozone surface activation;

[0042] The polyester material after ozone activation was transferred to another reaction bottle, and vacuum degassed for 120 minutes.

[0043]B. React the surface-activated polyester material with an aqueous solution of acrylic acid monomer to graft and copolymerize acrylic acid on the surface; the concentration of the aqueous solution of acrylic acid monomer is 25 wt%, the polymerization reaction temperature is 60° C., and the time is 240 minutes.

[0044] C, the terylene material that the surface graft copolymerization acrylic acid that B step obtains is immersed in the phosphate buffer solution of 1-(3-dimethylaminopropyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com