Nonpolar GaN film and growth method thereof

A growth method and non-polar technology, applied in the field of non-polar GaN thin film and its growth, can solve the problems of reducing device efficiency, high cost, reducing luminous efficiency, etc., and achieve the effect of improving surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further illustrate the specific implementation steps of the present invention below in conjunction with accompanying drawing:

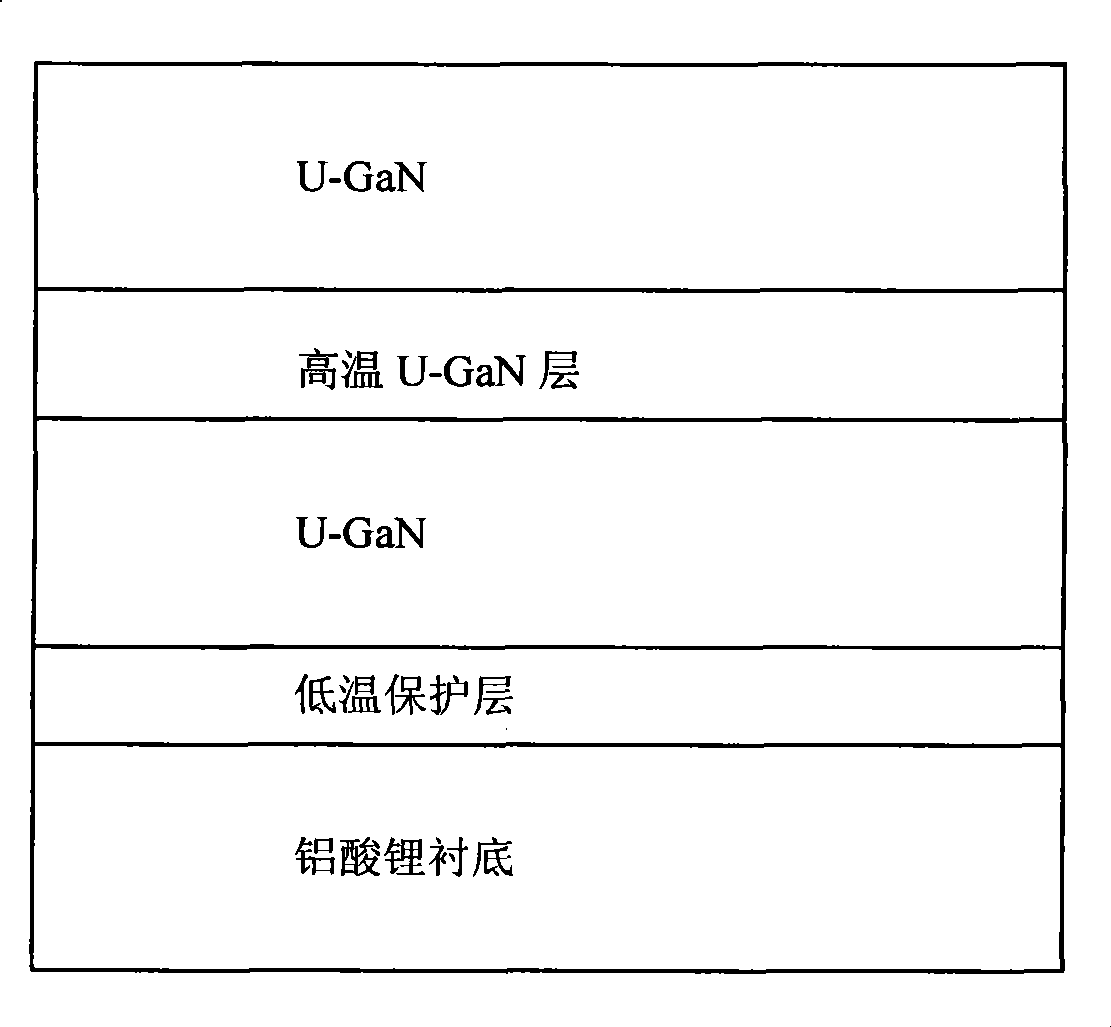

[0016] A non-polar GaN thin film, which is synthetically grown on a lithium aluminate substrate by using an MOCVD system. The thin film includes a low-temperature protective layer, a U-GaN layer, a high-temperature U-GaN layer and another a U-GaN layer.

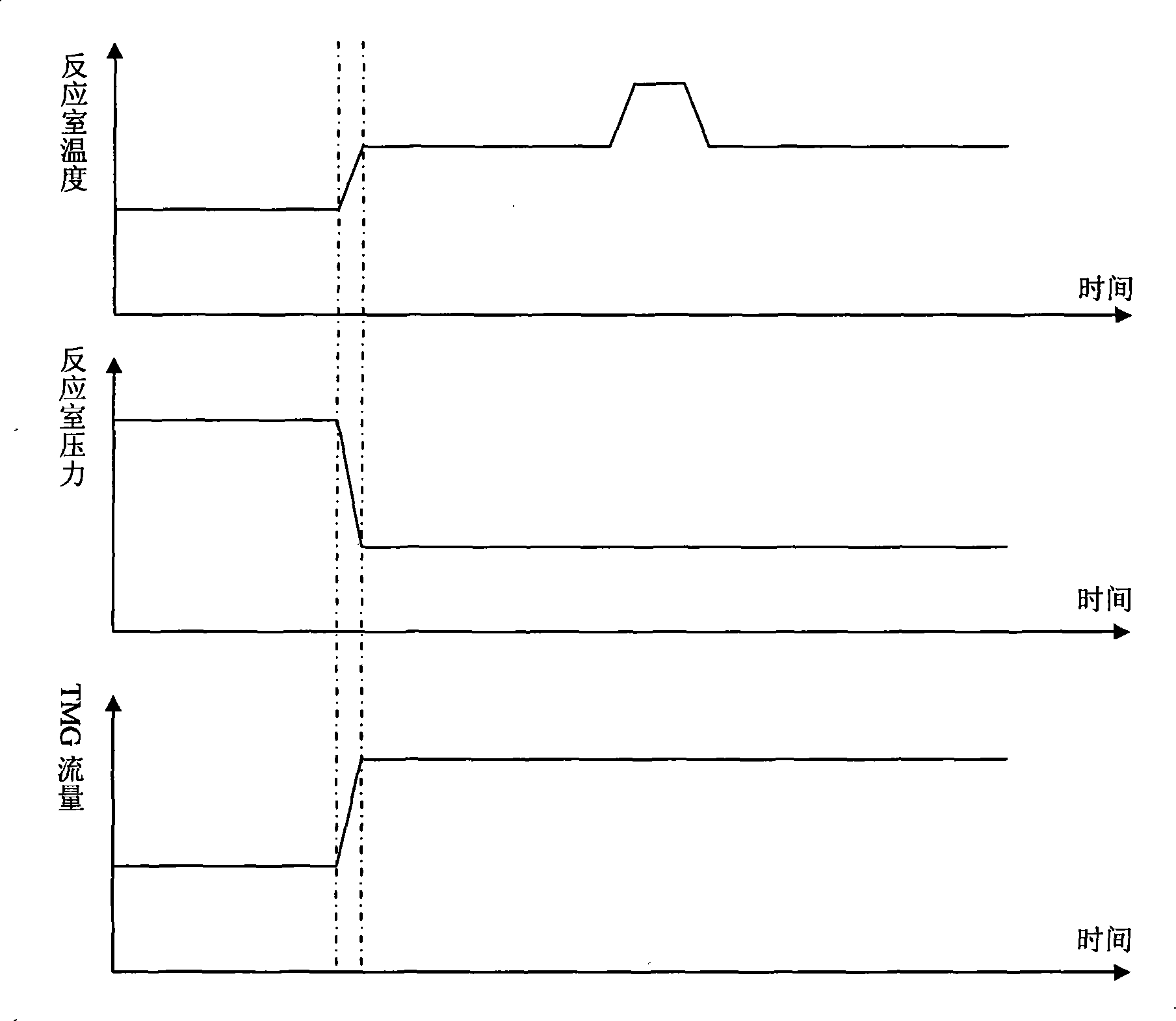

[0017] A kind of growth method of nonpolar GaN film, in MOCVD system, in N 2 Under protection, (in-situ heat treatment can be performed at 600-900°C or not) the temperature is raised to 800-900°C to grow a low-temperature protective layer. The pressure of the low-temperature protective layer is relatively high (150-500torr), and the TMGa flow rate is relatively low (1 -50sccm, corresponding to the molar flow rate: 4E-6mole / min—3E-4mole / min), then reduce the pressure (100-300torr), raise the temperature to 1000-1100°C to continue growing the U-GaN layer, and the TMGa flow rate is relatively hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com