Process for treating heavy-metal waste water containing high concentration suspended matter

A technology for wastewater treatment and suspended solids, which is applied in the field of resources and the environment, can solve problems such as the decline in utilization rate, achieve the effect of reducing load and avoiding regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

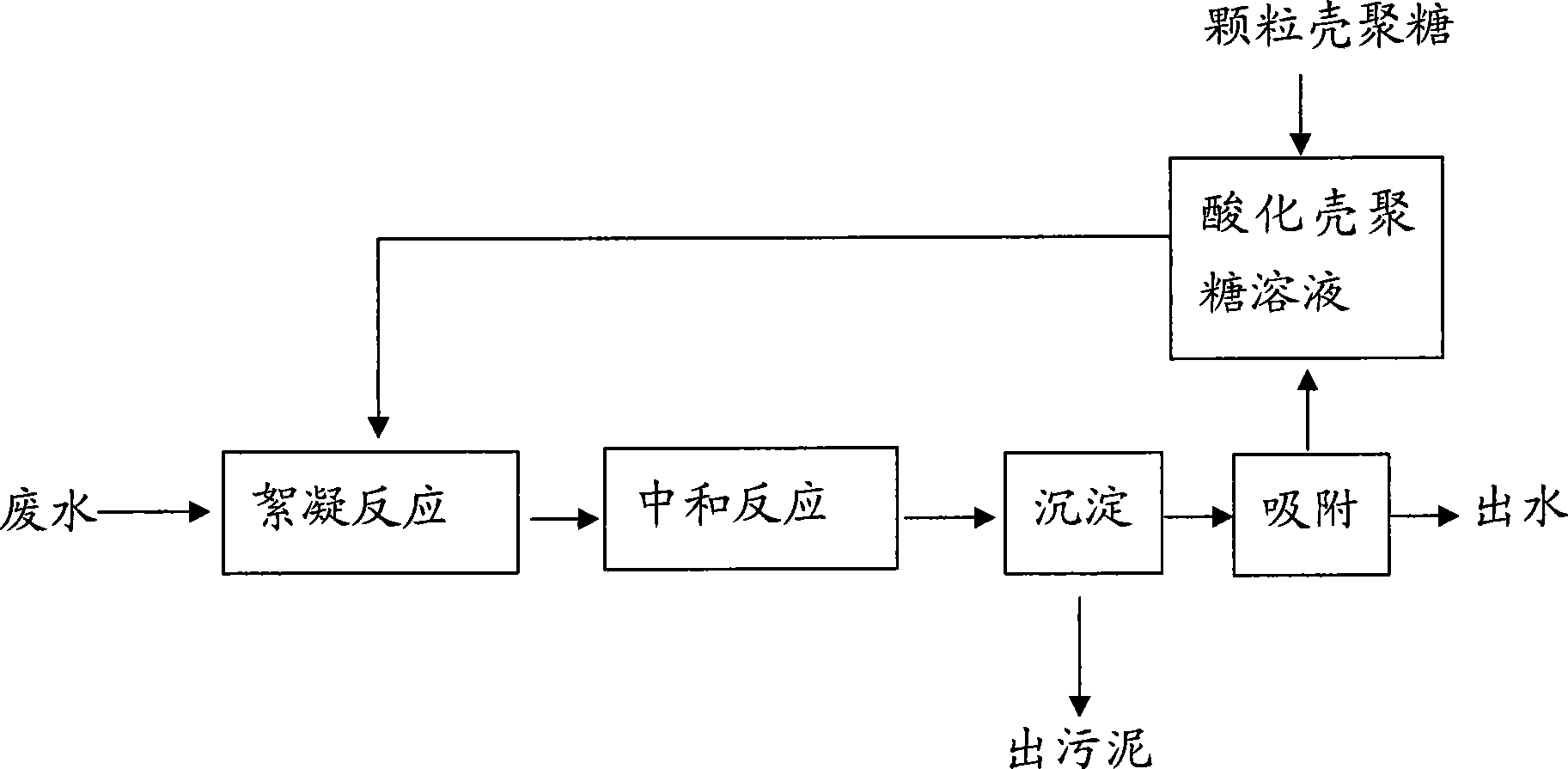

Image

Examples

Embodiment 1

[0018] Treatment containing suspended matter SS=50g / L, Mn 2+ =50mg / L, Cu 2+ =50mg / L of waste water.

[0019] Using hydrochloric acid as an acidifying agent, hydrochloric acid and granular chitosan were acidified in an acidizing tank to form a 5% soluble chitosan solution, and the pH value of the solution was 3.0. The waste water enters the flocculation reaction tank and the chitosan solution flowing out from the acidification tank undergoes metal chelation and flocculation reactions. polysaccharide 0.2g / L waste water).

[0020] Milk of lime is used as the neutralizing agent, and the neutralizing agent is added to the wastewater after the above reaction. After neutralization, the pH value is about 7.0, and then the wastewater enters the sedimentation tank for clarification and sludge concentration, and the supernatant is sent to the adsorption column.

[0021] The adsorption column is filled with 20 mesh fine granular chitosan. After the adsorbent reaches saturation, replac...

Embodiment 2

[0024] Treatment containing suspended matter SS=20g / L, Mn 2+ =50mg / L, Zn 2+ =50mg / L of waste water.

[0025] Sulfuric acid is used as an acidifying agent, and sulfuric acid and granular chitosan are acidified in an acidizing tank to form a 1% soluble chitosan solution with a pH value of 2.5. The waste water enters the flocculation reaction tank and the chitosan solution flowing out of the acidification tank has metal chelation and flocculation reactions, and the amount of chitosan is 0.8g / L waste water (wherein directly adding chitosan 0.4g / L waste water, comes from the shell of adsorption saturation polysaccharide 0.4g / L waste water).

[0026] Milk of lime is used as the neutralizing agent, and the neutralizing agent is added to the wastewater after the above reaction. After neutralization, the pH value is about 8.0, and then the wastewater enters the sedimentation tank for clarification and sludge concentration, and the supernatant is sent to the adsorption column.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com