Separation method for light hydrocarbon products in MTO/MTP reaction products

A technology for reaction products and separation methods, applied in distillation purification/separation, hydrocarbon purification/separation, chemical instruments and methods, etc., can solve problems such as increased equipment investment, energy consumption, and complex separation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

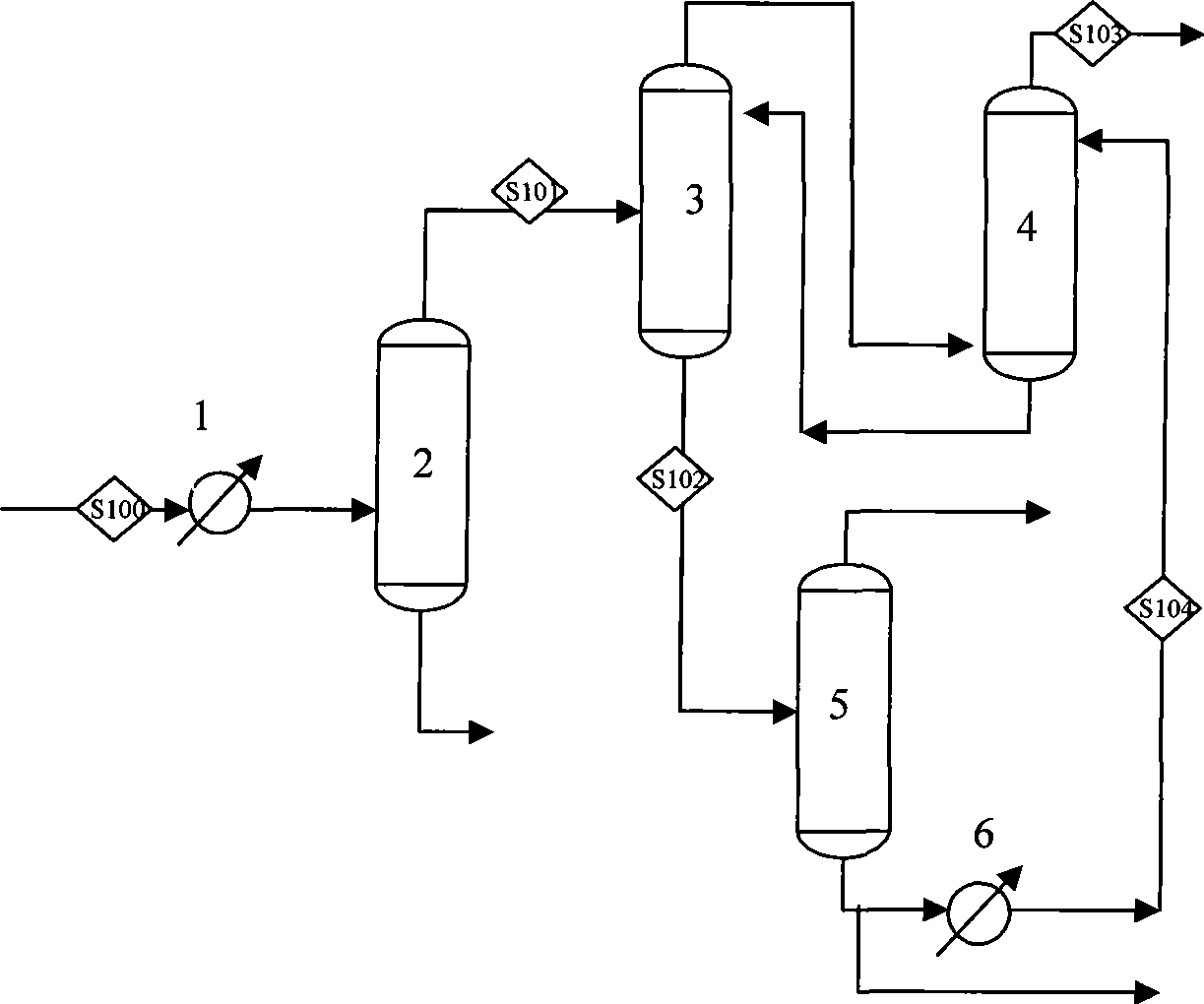

[0027] like figure 1 As shown, a certain reaction product is compressed, washed with water, washed with alkali, deoxidized and dried before entering the separation system. The gas is separated from carbon 3 and carbon 4 through the high and low pressure depropanizer, the still liquid of the low pressure depropanizer enters the debutanizer for separation of carbon 4 and carbon 5, and the gas phase at the top of the high pressure depropanizer is compressed to 3MPa. S100 is cooled to -20°C and then enters the deethanizer 2 for carbon 2 and carbon 3 separation, and the product from the tower still enters the propylene tower for separation to obtain polymer-grade propylene products. Deethanizer 2 tower top carbon two and lighter fractions S101 enter the absorption and distillation tower 3 for absorption and separation, the top gas phase is absorbed in the oil absorption tower 4, and the oil absorption tower 4 tower top S103 is methane, hydrogen and other light components Divide th...

Embodiment 2

[0032] like figure 1As shown, a certain reaction product is compressed, washed with water, washed with alkali, deoxidized and dried before entering the separation system. The gas S100 is cooled to -20°C and then enters the deethanizer 2 for C2 and C3 separation, the product from the tower still enters the depropanizer for C3 / C4 separation, and the top product of the depropanizer enters the propylene tower to obtain polymerization grade propylene , the still liquid of the depropanizer enters the debutanizer for C4 / C5 fraction separation. Deethanizer 2 tower top carbon two and lighter fractions S101 enter the absorption and distillation tower 3 for absorption and separation, and the tower top gas phase is recovered in the oil absorption tower 4, and the oil absorption tower 4 tower top S103 is light such as methane and hydrogen. Component gas, the tower still returns to absorb the distillation tower 3 as a rich absorbent, and the carbon two fraction S10 of the absorption distil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com